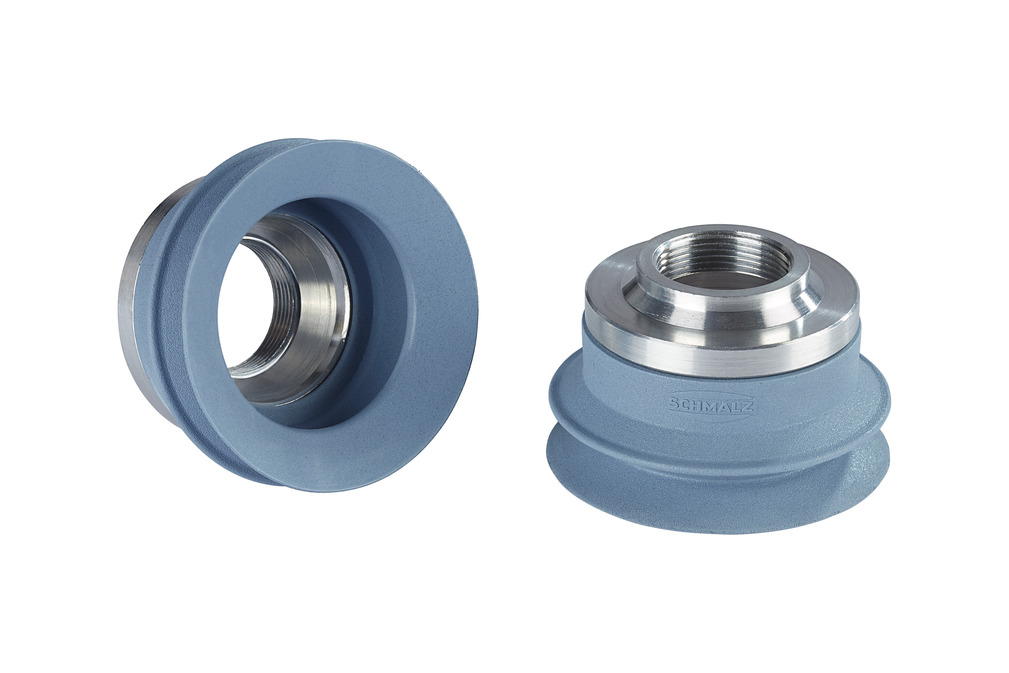

Suction Cups for Flow Grippers SCGS

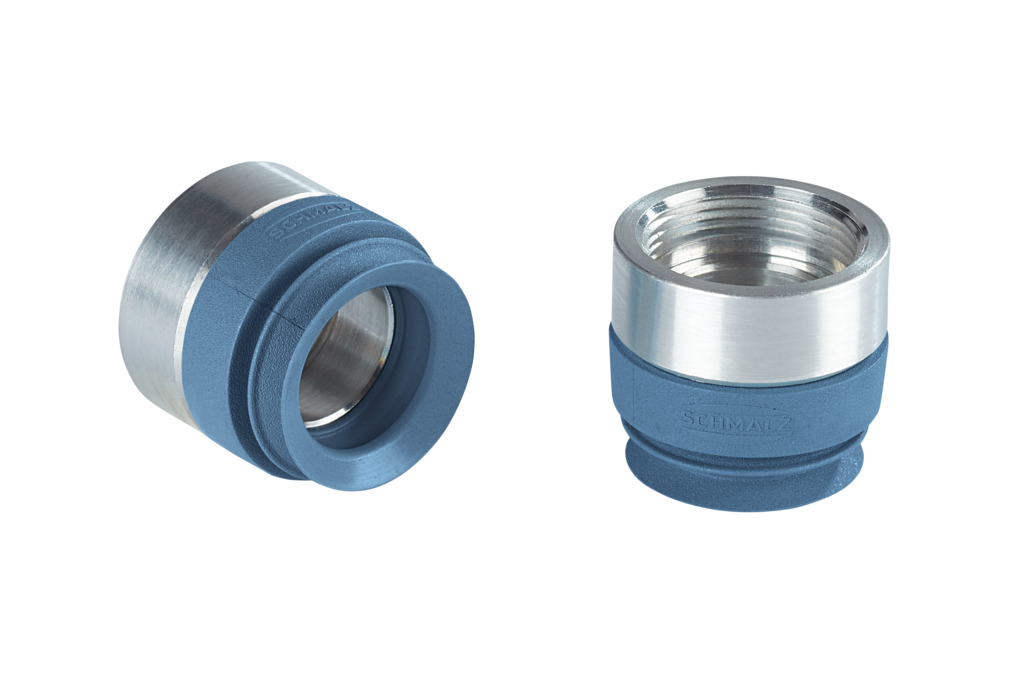

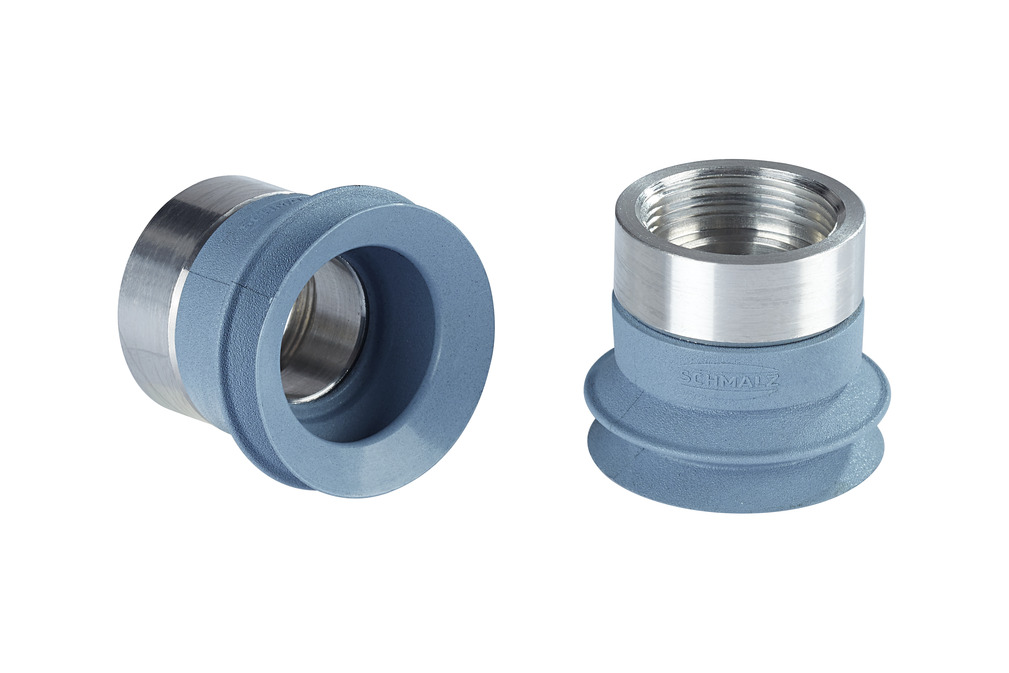

Contact elements optionally food-safe (POM, SI-MD und SI-HD) or conductive for electrostatic discharge (HT1-ESD and NBR-ESD)

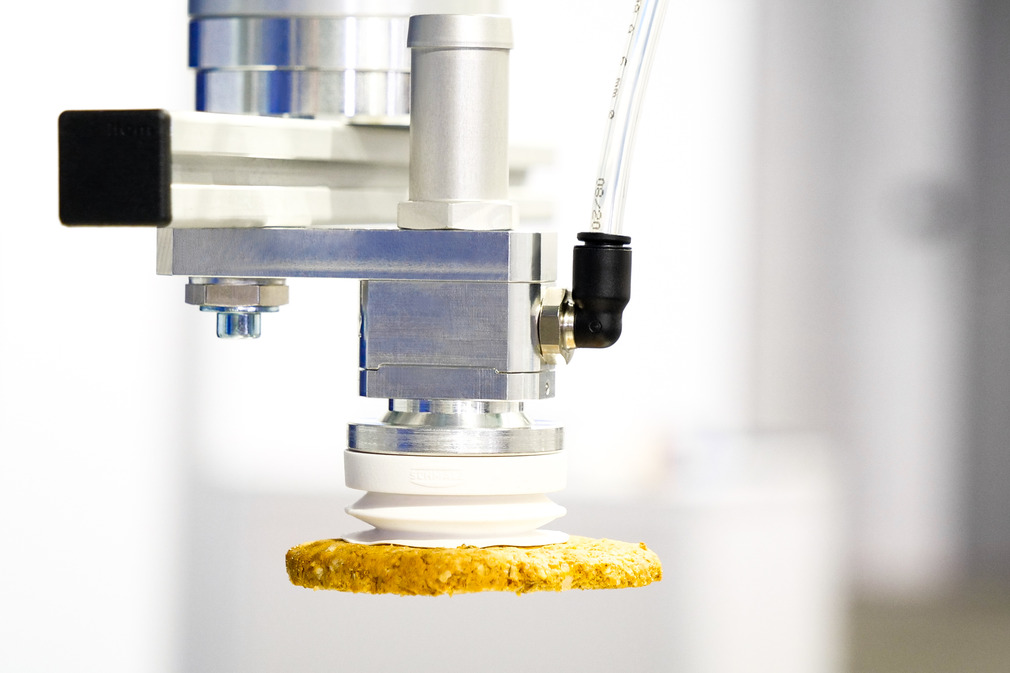

Very high suction flow rate enables safe gripping even of porous, highly structured workpieces

Soft, flexible sealing lip for best damping and sealing on structured surfaces such as biscuits

Suction surface made of POM prevents suction and damage to the workpiece

Suction cup can be dismantled without tools for easy cleaning

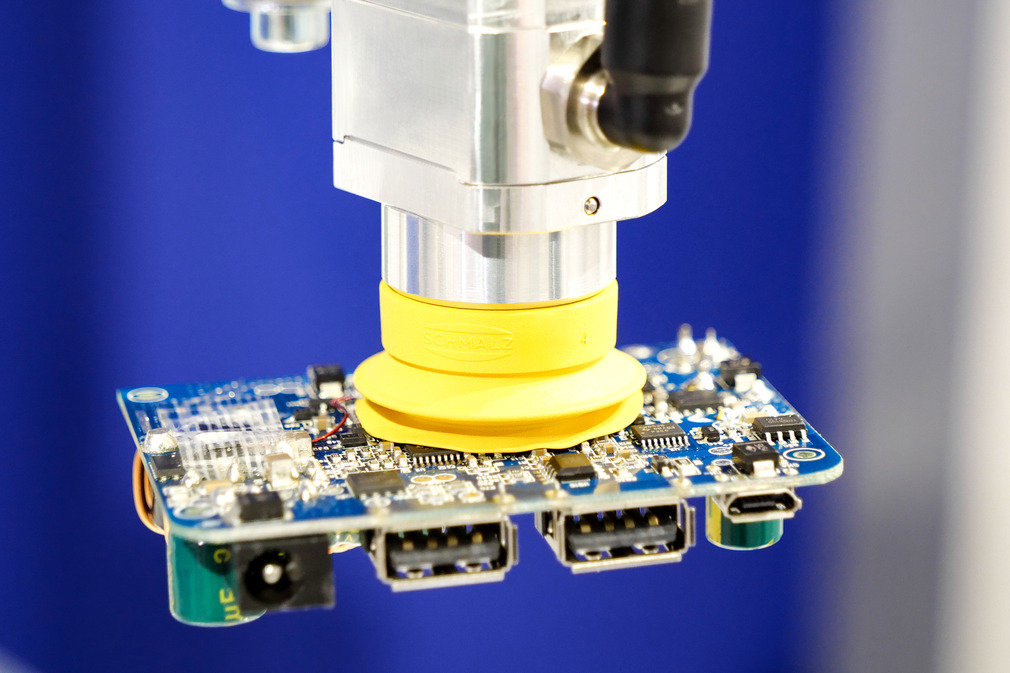

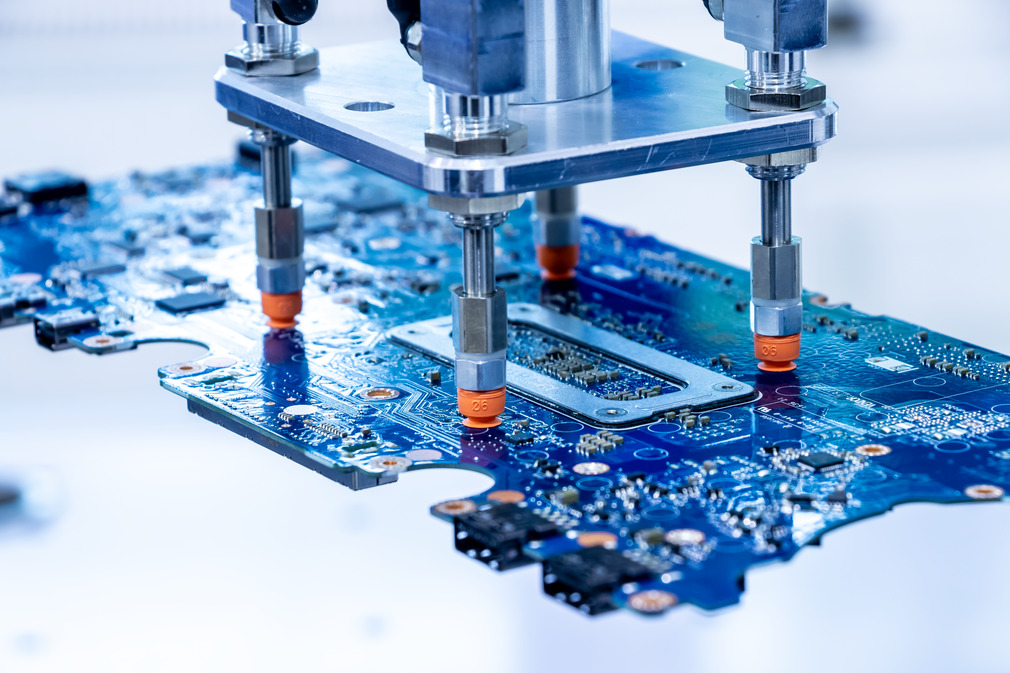

Sensitive Electronics Perfectly Handled – Minimized Marks, Maximized ESD Protection

In electronics manufacturing, there is no second chance. One tiny mark, one static discharge and entire batches are ruined. Not with us!

Our innovative suction cups made the material of HT1-ESD solve these challenges and many more: They protect workpieces from unwanted marks and ESD damage. With our suction cups, you benefit from:

- Clean surfaces

- Maximum component safety

- Reliability at high temperatures

- High system availability and cost efficiency

Thanks to our extensive expertise in material development, the suction cup material HT1-ESD stands for cutting-edge technology and sets new standards in electronics manufacturing.

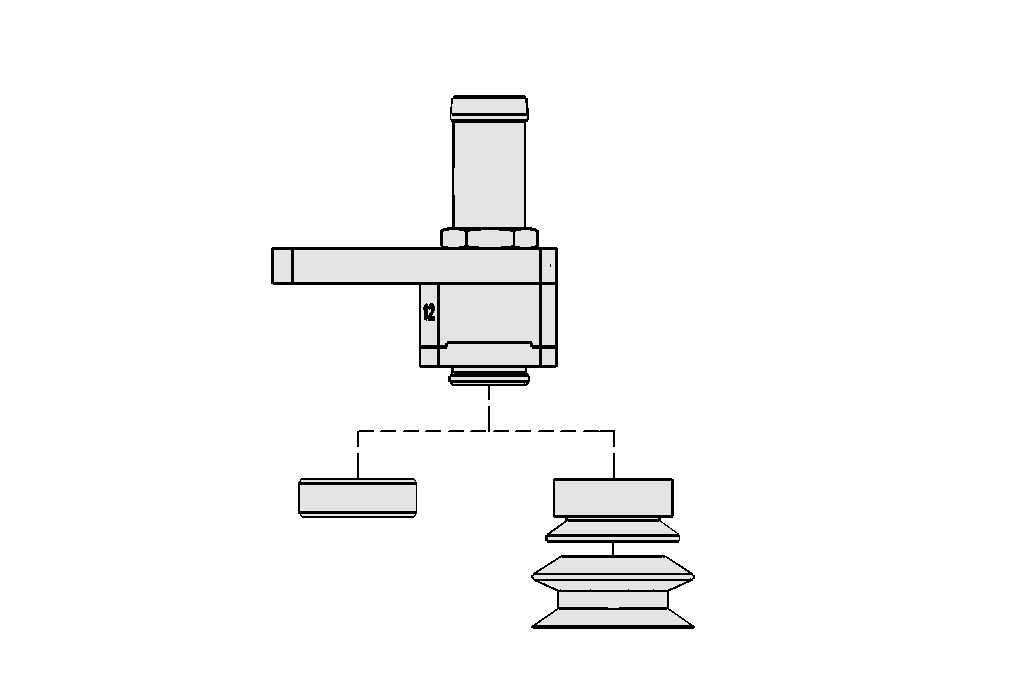

Design

- Suction cup connector made from aluminum (FDA compliant)

- Suction cups (Ø 20-50 mm) made of FDA-compliant SI-MD, SI-HD and electrostatic HT1-ESD, NBR-ESD

- Gripping surface made out of POM (Ø 30 mm)

- Large shaft diameter for high flow rates

Technical Data

- Diameter suction area: 30 mm

- Diameter suction cup: 20 to 50 mm

- Suction areas made of FDA compliant POM

- Suction cups made of SI-MD, SI-HD, HT1-ESD, NBR-ESD

Documentation

The matching documentation for this product is available in this section.

| Documents | Language |

|---|---|

| Serbian |

The documentation is also fully available in English.

| Documents | Language |

|---|---|

| English |

1 - 10 from 25 results