AI power for sheet metal production

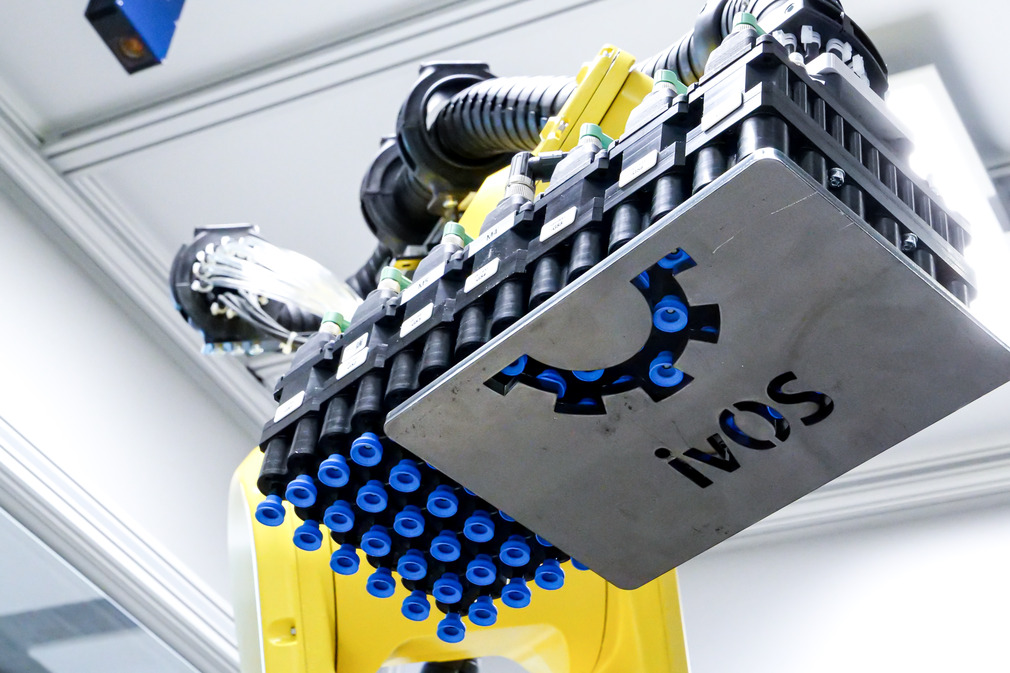

The ivOS Sheet Metal Solution Kit from Schmalz consists of a software package, an intelligent vacuum matrix gripper and 3D vision sensors.

"We are specialists when it comes to optimizing work processes," says Daniel Wechsel. He is Head of Sheet Metal Production at LISSMAC Maschinenbau GmbH. This is why the company is constantly looking for solutions to increase its own productivity and improve its systems. In sheet metal production, employees loaded and unloaded the deburring machines - one person was required for each machine. "The shortage of skilled workers repeatedly led to bottlenecks. Our goal was therefore to load the machines automatically in order to relieve our employees," says Daniel Wechsel, summarizing the task.

The AI-supported part recognition works extremely reliably - and saves noticeable time, as the tedious manual placement of workpieces is now a thing of the past.∼ Daniel Wechsel, Head of Sheet Metal Production at LISSMAC Maschinenbau GmbH

Founded in 1978, LISSMAC specializes in construction machinery such as floor saws and stone cutting saws, grinding and deburring machines and handling systems. With around 380 employees worldwide, the Group, based in Bad Wurzach in Upper Swabia, generated around 68 million euros in 2023. Exports account for more than 40 percent of sales, and this figure is rising - the company is active in Europe, America, the Middle East, Australia and New Zealand, with mounting and service locations in the USA and Dubai.

Partnership at eye level

With its deburring machines, LISSMAC processes workpieces made of aluminum, steel and stainless steel from a size of 150 × 50 millimeters and up to a diagonal of 950 millimeters, the thickness varies between 0.8 and 20 millimeters. The components differ in their internal contours and the surfaces can be dry or wet. "For automation, the system must be able to reliably recognize the parts," explains Daniel Wechsel. "We have been working with our partner Schmalz on vacuum and gripping solutions for a lengthy period of time. When we heard about the Solution Kit for sheet metal processing, we were immediately interested."

As a technology expert for the interaction between robots and grippers, Schmalz not only contributed the ivOS solution kit, but also the FMG matrix area gripper. Schmalz linked seven modules for this, each suction cup can be controlled individually. The FMG is characterized by a low vacuum requirement, it holds suctioned workpieces even if the actuator voltage is lost. The highlight, however, is the artificial intelligence (AI) in the Solution Kit ivOS Sheet Metal. It reacts flexibly to changing requirements and workpieces without the need for a teach-in process. "The AI-supported part recognition works extremely reliably - and saves noticeable time, as the tedious manual placement of workpieces is now a thing of the past," confirms the Head of Sheet Metal Production.

From a manual to an automated process

The employees feed the workpieces into the robot cell in single-variety stacks on a pallet. Only one sheet thickness is allowed in each shrink wrapped good. 3D vision sensors mounted on the ceiling of the cell detect different sheet geometries and provide the necessary data for robot control. This allows the gripper to be positioned precisely and place the sheet metal accurately on the conveyor belt of the deburring machine. Schmalz and LISSMAC defined rules for this and connected the robot cell and deburring system via an interface.

The system places 700 to 1,000 workpieces per shift fully automatically into the LISSMAC sanding machine. The system still has large reserves - if required, it can handle up to 500 parts per hour. After deburring, a conveyor belt transports the processed parts, from which they are currently still removed manually. "The Solution Kit has become an important tool in our sheet metal production," emphasizes Daniel Wechsel. The worker now loads and unloads two deburring machines at the same time. "This allows us to deploy our staff much more efficiently," he says happily. There is only one restriction: the sheet metal parts require a minimum web width of 30 millimetres for the grippers to be able to grip them.

The system has been in regular operation since August 2024. The robot solution has been well received by the staff, as they are now relieved of repetitive tasks. "Operation is intuitive and the system works reliably," says the head of sheet metal production, summarizing the experience. "We can now deploy our skilled workers on several machines at the same time. This significantly increases productivity."

The next step

As a machine manufacturer, LISSMAC naturally thinks ahead with the automation solution. "We have a great product with a lot of potential. That's why we don't just want to use the Solution Kit for our own production, but also make it available to our customers," says Daniel Wechsel. This is why LISSMAC and Schmalz are developing a modular system for different payloads and part geometries. "Of course, full automation also includes a solution for removal directly after machining. We are currently working on this. The system will then be able to meet any challenge."

The matrix area gripper FMG automates the loading of deburring machines in sheet metal processing, for example.

The system recognizes different workpieces without a teach-in process and controls the gripper precisely.

The robot cell loads the LISSMAC deburring machine fully automatically.

Pressekontakt

Für Rückfragen steht Ihnen das Schmalz Presseteam gerne zur Verfügung.