Schmalz at automatica: Technology gets to work here

The Solution Kit ivOS Wood demonstrates intelligence - thanks to a vacuum gripping system, 3D camera and AI-supported software, it packs varying workpieces fully automatically.

With the Solution Kits ivOS, Schmalz enables the design of application-specific, automated handling solutions. The combination of vacuum gripping system, 3D camera and AI-supported software recognizes, grasps and moves unknown and varying workpieces - from batch size 1. The versions for logistics (fast picking) and sheet metal for sheet metal handling are joined by the new Solution Kit ivOS Wood. It is tailored to the requirements of furniture manufacturing companies and loads and unloads CNC, drilling and other processing machines, for example. Painting processes can be automated and made significantly more efficient, as can the destacking of single components from nesting machines. Joineries save their staff from monotonous tasks and at the same time counteract the shortage of skilled workers.

Advantages of electrical vacuum generation

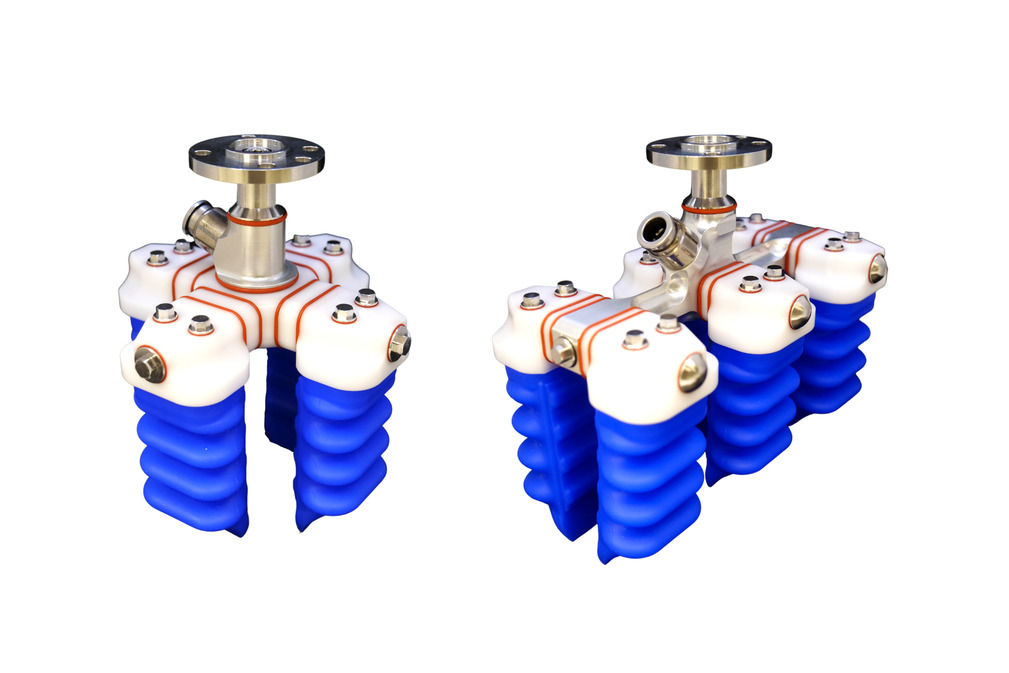

In addition to proven pneumatic vacuum generators, Schmalz will also be presenting innovative purely electrical systems for automated handling at its booth. For the first time, the company will be showing the lightweight layer gripper ZLW with electrical vacuum generation - ideal for moving entire workpiece layers such as glasses, cans or cardboard boxes. The Compact-Pump GCPi double-head diaphragm pump in combination with the LQEi compact valve enables particularly short cycle times thanks to pre-evacuation and fast venting - comparable to pneumatics. The compact vacuum generator ECBPMi is mounted directly on the end-of-arm and, thanks to its diameter, fits perfectly with standard robot arms.

Efficient material handling with vacuum grippers

Schmalz focuses on high efficiency with the new area grippers FA-X: the system reduces compressed air consumption by 80 percent. The grippers are used for palletizing, depalletizing, picking or sorting cardboard boxes, sheet metal, wood or plastic workpieces.

In the food industry in particular, companies have to pick and pack products that have delicate surfaces and can vary greatly in shape - from chicken drumsticks and peppers to soft donuts. The finger gripper mGrip adapts to all objects thanks to circular or parallel grippers and different finger module sizes. Hygienic design and IP69K certification ensure that the system can withstand high temperatures or high-pressure water and protects against the ingress of dust. As a result, the finger gripper is easy to clean - it is designed for both clean-in-place (CIP) and clean-out-of-place (COP) processes. Such adaptable systems are also used in other industries, for example when handling nets or bags with small parts. They enable fast and continuous picking without the need for personnel to be constantly available.

Keep your back free

The forward bend exoskeleton MATE UBA supports the lower back when lifting and depositing goods - especially during repetitive tasks, for example when employees remove goods from low shelves. The upper body exoskeleton MATE UTA relieves strain on people when carrying out overhead work such as mounting plasterboard on ceilings or loading and unloading freight containers stacked at a height. The systems do not require an external energy source, they are lightweight and suitable for outdoor use.

Also on display is the tried-and-tested JumboFlex vacuum tube lifter, which Schmalz has redesigned. Its handle now fits even better in the hand - regardless of its size. It is intuitive to use and significantly reduces the training time for new skilled workers.

Schmalz at automatica: Hall A5, Stand 301

Its small dimensions and low weight make the vacuum generator ECBPMi ideal for robots with payloads of up to three kilograms.

The area gripper FA-X enables users to realize short process cycles.

The finger gripper mGrip grips - whether marshmallow or steak.

The forward bend exoskeleton MATE UBA supports the bottom of the back when lifting and placing goods.

Media contact

The Schmalz press team will be happy to answer any questions you may have.