Schmalz at the aaa 2026: Automating as light as a feather

Thanks to the modular gripper system PXT, applications can build flexible systems with just a few standard parts and little effort.

Automation specialists are under pressure: they need to lower energy costs and increase the availability of their systems at the same time. The electrical Compact-Pump GCPi works completely without compressed air and is therefore very energy-efficient. Using 24-volt technology, it generates vacuum purely electrically and vents when the workpiece is deposited. It is particularly suitable for decentralized installation directly on the machine. In combination with the compact valve LQEi directly on the gripper, the GCPi shortens cycle times thanks to fast ventilation functions and handles both air-tight and porous workpieces reliably.

The integrated control unit monitors the entire vacuum system. Thanks to IO-Link and NFC interfaces, it can be initialized quickly and integrated cost-effectively into existing control systems. For operations with mobile robots (AMR) or autonomous transport systems (AGV), the electrical compact pump GCPi offers additional advantages: it works independently of compressed air supply and reduces infrastructure costs.The electrical vacuum generator ECBPMi, which is particularly suitable for mobile and lightweight robotics as well as human-robot collaboration (HRC) thanks to its low weight, will also be on display at the stand.

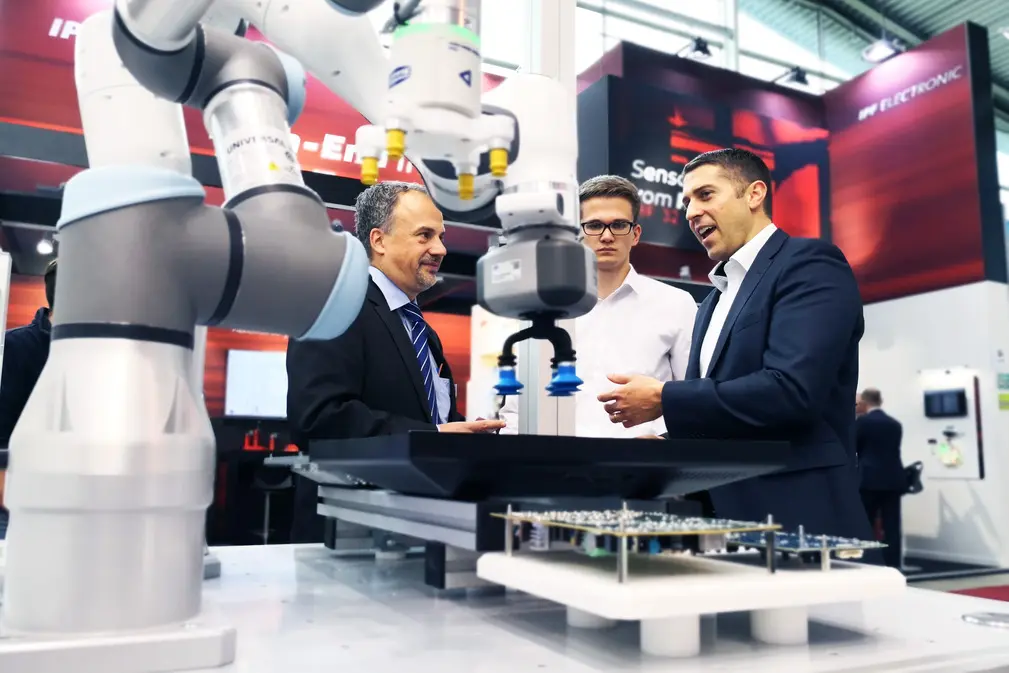

Modular and fast: the modular gripper system PXT

The modular gripper system PXT enables operations to put together gripper systems for lightweight robots quickly and easily. The modular system consists of standardized components. Users can configure the gripper themselves and assemble it with just a few tools. If required, they can also obtain a ready-to-use system from Schmalz. They can use it to handle workpieces weighing up to 25 kilograms and achieve a maximum gripping range of 800 × 600 millimetres.

One particular advantage is the optional internal vacuum guide. It eliminates external hoses and reduces interfering contours to a minimum. The system is therefore also suitable for confined spaces, for example when removing injection-molded parts. If workpiece geometries change, the components can be recombined or adjusted.

Flexible and energy-efficient: the matrix area gripper FMG

A high number of variants presents companies with challenges. The modular matrix area gripper FMG handles flat and predominantly air-tight workpieces of different shapes and dimensions fully automatically. Each FMG module weighs less than one kilogram and has between two and twelve individually controllable suction points. Applications can block several modules as required and control them via IO-Link. The suction points, which can be activated separately, guarantee high energy efficiency and pick up individual workpieces from complete storages.

With the Digital Engineering Service from Schmalz, users can easily automate their design processes and save around 80 percent of the time thanks to the digital design of the matrix area gripper. The result: an application-specific, scalable solution for the safe handling of different components is created without gripper changes and with noticeably less set-up time.

Schmalz at the aaa: Hall B2, Booth 410

The electrical compact pump GCPi is particularly impressive in Vacuum Automation as well as in autonomous transport systems (AGV) and robots (AMR).

The matrix area gripper FMG is equally suitable for heavy and small workpieces with complex geometries.

Media contact

The Schmalz press team will be happy to answer any questions you may have.