.jpg)

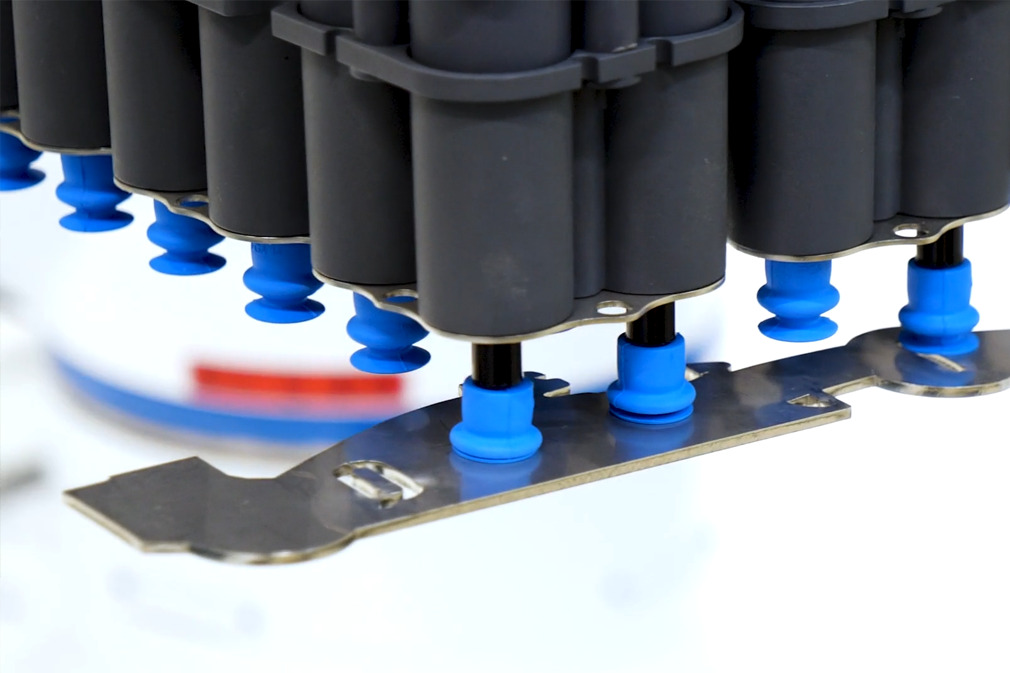

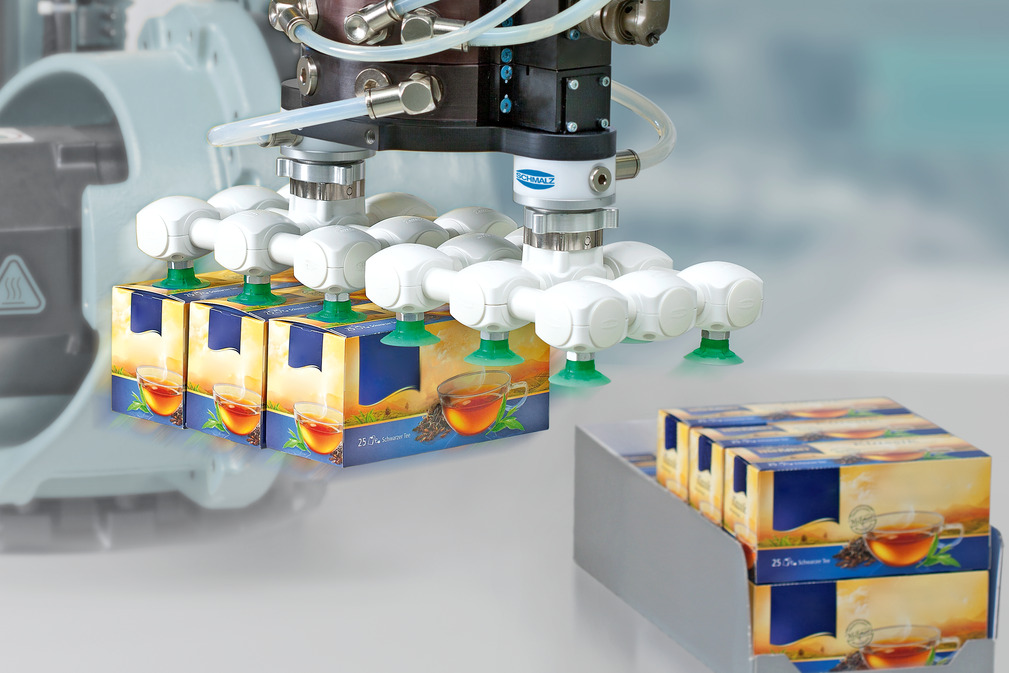

- VEE system expansion for handling complex 3D-shaped products

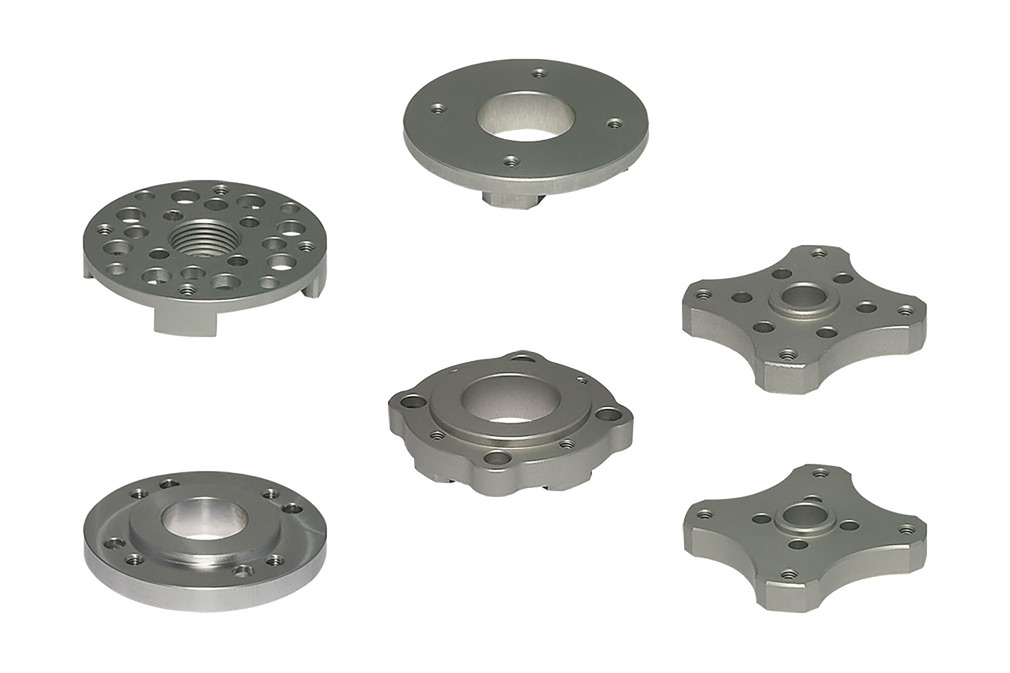

- Low weight by sintered polyamide

- Warp resistant gripper for increased cycle speed and load capacity

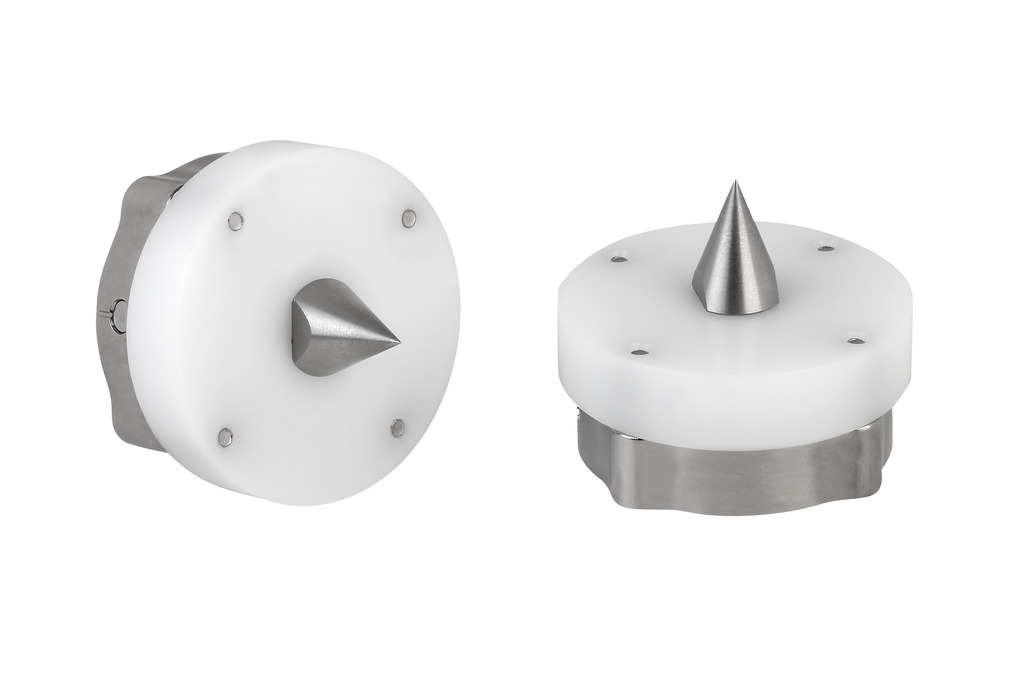

- Realization of complex custom-shaped grippers by innovative sinter technology

- Hose-free vacuum distribution (standard) and integrated vacuum generator (option)

.jpg)

.jpg)

.jpg)

.jpg)