- EFFICIENT

| Communication | Ethercat |

| Number of ejectors | 4 |

| SCPSt 15 G02 NO | |

| SCTSi-ECT-4-AB-4C7A-00 |

Variety, optimization of production processes, and continuous energy and process control are the challenges of the future. In order to meet these demands, powerful, flexible and energy-efficient vacuum systems are required. The answer is our Compact Terminal SCTSi Ethernet, a compact unit of several vacuum generators for simultaneously and independently handling different parts with a single vacuum system.

The compact terminal SCTSi is sort of the masterpiece of our engineers, a compact and powerful unit for vacuum generation in automated systems. Now Schmalz has enhanced the Ethernet version of the terminal by adding new modules. Via an IO-Link master that can be integrated into the terminal, field devices can be connected via IO-Link and thus communicate directly with the PLC. Digital field devices such as sensors are integrated via digital input modules – without separate I/O modules. The terminal thus becomes the central control unit for vacuum gripping systems.

Direct communication with the system controller via Ethernet interface (EtherCat, EtherNet/IP or ProfiNet)

NFC interface allows diagnosis and parameterization via smartphone

Central compressed air and power supply for up to 16 ejectors minimizes hosing effort

Individually controllable vacuum circuits allow handling of different parts

Condition monitoring for predictive maintenance and increased plant efficiency

Your Individual Configuration

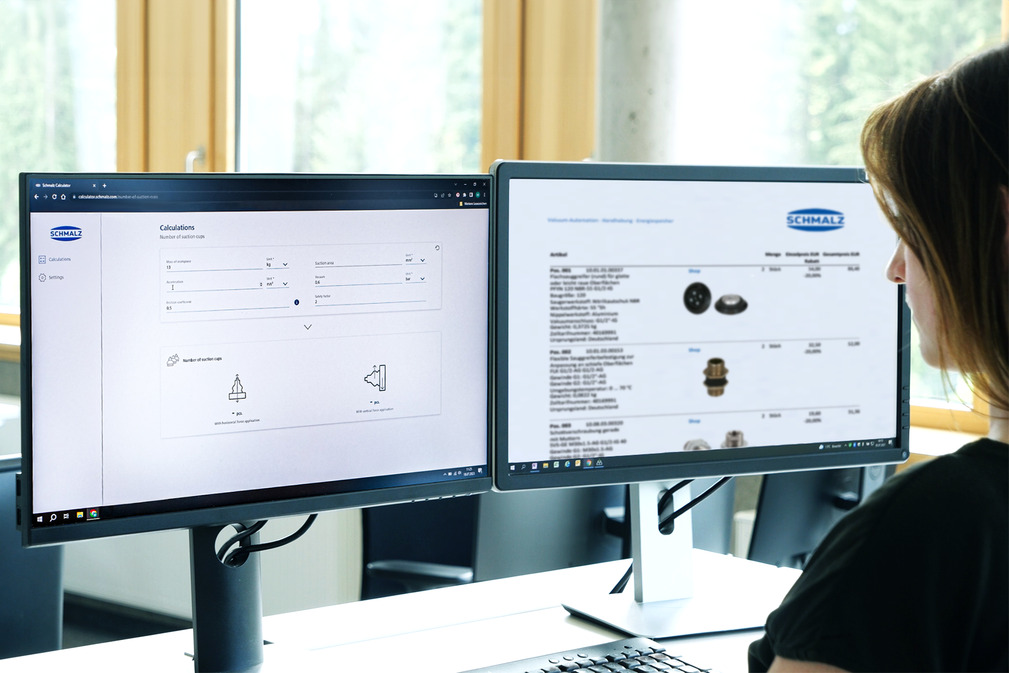

The compact terminals SCTSi offer the flexibility to design the handling process entirely according to your needs. Thanks to innovative configurators, our sales staff can create a custom-made solution for you in no time at all.

In addition to an offer for your individual product, you will also receive a CAD model.

Request your personal configuration now and contact us!

.jpg)

Product code

Similar to a part number, the product code is used to uniquely identify product configurations at Schmalz. The product code can be found on the product label or on the quotation or order. Do you have questions about your product or would you like to order a configuration again? Then please have this key ready when you contact Schmalz.

| Code | Type |

|---|---|

| SCTSI | SCTSi |

| Code | Type |

|---|---|

| EIP | EthernetIP |

| ECT | EtherCat |

| PNT | ProfiNet |

| Code | Type |

|---|---|

| E + number | Number of ejectors |

| V + number | Number of valves |

| E + number V + number | Number of ejectors and number of valves |

| Code | Type |

|---|---|

| I + number | Number of IO-Link modules |

| D + number | Number of digital modules |

| I + number V + number | Number of IO-Link and digital modules |

| Code | Type |

|---|---|

| ABC00001C | Individual configuration code |

Ordering information

| Variant | Type |

|---|---|

| SCTSi-PNT | Main body SCTSi Ethernet interface Communication: ProfiNet |

| SCTSi-ECT | Main body SCTSi Ethernet interface Communication: EtherCAT |

| SCTSi-EIP | Main body SCTSi Ethernet interface Communication: Ethernet/IP |

| Variant | Type |

|---|---|

| 0-16 | Number of ejectors |

Note:

A maximum of 16 ejectors can be integrated in one terminal.

A version without ejectors for use as a central control unit is also possible.

| Variant | Type |

|---|---|

| AA | Standard version, push-in vacuum connection, hose outer diameter = 6 mm (for nozzle size = 0.7 mm and 1.0 mm) or hose outer diameter = 8 mm ( for nozzle size = 1.5 mm) |

| AB | Standard version, threaded connection, G1/8"-F (for all nozzle sizes) |

| NE | Standard version, without ejectors |

| Variant | Type | Option of terminal | Suction rate l/min | Air consumption l/min | Part no. |

|---|---|---|---|---|---|

| C8B | SCPst 07 GS01 NC C8B | AA | 16 | 22 | 10.02.02.05957 |

| C79 | SCPSt 07 GS01 NO C79 | AA | 16 | 22 | 10.02.02.05954 |

| C8N | SCPSt 10 GS01 NC C8N | AA | 36 | 46 | 10.02.02.05984 |

| C8A | SCPSt 10 GS01 NO C8A | AA | 36 | 46 | 10.02.02.05956 |

| C7U | SCPSt 15 GS02 NC C7U | AA | 65,5 | 98,5 | 10.02.02.06203 |

| C78 | SCPSt 15 GS02 NO C78 | AA | 65,5 | 98,5 | 10.02.02.06202 |

| C7E | SCPSt 07 G02 NC C7E | AB | 16 | 22 | 10.02.02.06187 |

| C7H | SCPSt 07 G02 NO C7H | AB | 16 | 22 | 10.02.02.06184 |

| C7D | SCPSt 10 G02 NC C7D | AB | 36 | 46 | 10.02.02.06188 |

| C7B | SCPSt 10 G02 NO C7B | AB | 36 | 46 | 10.02.02.06185 |

| C7N | SCPSt 15 G02 NC C7N | AB | 65,5 | 98,5 | 10.02.02.06189 |

| C7A | SCPSt 15 G02 NO C7A | AB | 65,5 | 98,5 | 10.02.02.06186 |

Note:

You can choose between different nozzle technologies and sizes, Connections or rest positions of the suction valve (NO/NC/IMP).

A maximum of 4 different ejector blocks are possible.

From 9 ejectors upwards, a larger hose diameter is required for compressed air supply.

| Variant | Type |

|---|---|

| 2 | Number of IO-Link masters |

| 4 | Number of DI modules |

Note:

A maximum of 6 modules can be integrated in one terminal.

0 to 2 IO-Link masters and 0 to 6 DI modules, depending on the combination.

| Type | Operating temperature [°C] |

Pressure range (operating pressure) [bar] |

Electrical connection | Communication |

|---|---|---|---|---|

| SCTSi Ethernet | 0...50 | 2...6 | M12, 5-pin plug | Ethernet |

| Type | Nozzle Size [mm] |

Degree of evacuation [%]* |

Max. suction rate [m³/h]* |

Max. suction rate [l/min]* |

Vacuum air consumption [m³/h]* |

Air consumption for blow off [m³/h]* |

Sound level free* [dB(A)]** |

Sound level during gripping* [dB(A)]** |

|---|---|---|---|---|---|---|---|---|

| SCPSt 07... | 07 | 85 | 0.98 | 16.0 | 1.35 | 7.25 | 63 | 58 |

| SCPSt 10... | 10 | 85 | 2.21 | 36.0 | 2.85 | 7.25 | 73 | 60 |

| SCPSt 15... | 15 | 85 | 4.03 | 65.5 | 6.03 | 7.25 | 73 | 65 |

| SCPSt 2-07... | 2-07 | 85 | 2.28 | 37.0 | 1.35 | 7.25 | 63 | 58 |

| SCPSt 2-09... | 2-09 | 85 | 3.05 | 49.5 | 2.49 | 7.25 | 73 | 60 |

| SCPSt 2-14... | 2-14 | 85 | 4.40 | 71.5 | 5.04 | 7.25 | 75 | 65 |

*At optimal operating pressure (4 bar)

**No linear increase in sound level with increase in ejector disks

| 0 | 50 | 100 | 150 | 200 | 250 | 300 | 400 | 500 | 600 | 700 | 800 | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 0.7 mm | 0,01 | 0,15 | 0,31 | 0,48 | 0,67 | 0,91 | 1,19 | 1,85 | 2,72 | 4,00 | 6,07 | 10,50 |

| 2-0.7 mm | 0,00 | 0,00 | 0,00 | 0,08 | 0,15 | 0,35 | 0,40 | 0,85 | 1,75 | 2,70 | 4,20 | 7,20 |

| 0 | 50 | 100 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 550 | 600 | 650 | 700 | 750 | 800 | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 0.7 mm | 15,69 | 13,56 | 12,28 | 11,22 | 10,37 | 9,36 | 8,21 | 7,38 | 6,22 | 4,83 | 4,05 | 3,00 | 2,11 | 1,69 | 1,16 | 0,63 | 0,25 |

| 2-0.7 mm | 37,20 | 32,30 | 28,10 | 24,00 | 19,90 | 16,50 | 12,50 | 10,00 | 7,50 | 5,40 | 3,90 | 3,10 | 2,00 | 1,60 | 1,00 | 0,63 | 0,30 |

| 2 | 3 | 4 | 5 | 6 | |

|---|---|---|---|---|---|

| 0.7 mm | 477,81 | 700,18 | 867,18 | 855,86 | 838,29 |

| 2-0.7 mm | 334,00 | 564,57 | 789,19 | 892,20 | 885,26 |

| 0 | 100 | 200 | 300 | 400 | 500 | 600 | 700 | 800 | |

|---|---|---|---|---|---|---|---|---|---|

| 1.0 mm | 0,00 | 0,15 | 0,30 | 0,50 | 0,80 | 1,20 | 1,75 | 2,80 | 5,50 |

| 2-0.9 mm | 0,00 | 0,00 | 0,00 | 0,20 | 0,45 | 0,85 | 1,45 | 2,50 | 5,00 |

| 0 | 100 | 200 | 300 | 400 | 500 | 600 | 700 | 800 | |

|---|---|---|---|---|---|---|---|---|---|

| 1.5 mm | 0,00 | 0,07 | 0,15 | 0,25 | 0,40 | 0,60 | 0,90 | 1,30 | 2,30 |

| 2-1.4 mm | 0,00 | 0,00 | 0,00 | 0,10 | 0,20 | 0,35 | 0,65 | 1,20 | 2,30 |

| 2 | 3 | 4 | 5 | 6 | |

|---|---|---|---|---|---|

| 1.0 mm | 475,00 | 700,00 | 850,00 | 850,00 | 810,00 |

| 2-0.9 mm | 430,00 | 650,00 | 820,00 | 875,00 | 860,00 |

| 2 | 3 | 4 | 5 | 6 | |

|---|---|---|---|---|---|

| 1.5 mm | 450,00 | 660,00 | 870,00 | 880,00 | 865,00 |

| 2-1.4 mm | 390,00 | 590,00 | 800,00 | 890,00 | 880,00 |

| 0 | 100 | 200 | 300 | 400 | 500 | 600 | 700 | 800 | |

|---|---|---|---|---|---|---|---|---|---|

| 1.5 mm | 65,50 | 57,10 | 47,40 | 39,30 | 32,00 | 25,30 | 17,00 | 8,80 | 1,50 |

| 2-1.4 mm | 71,80 | 61,40 | 52,50 | 42,20 | 31,90 | 23,50 | 15,30 | 8,50 | 1,20 |

| 0 | 100 | 200 | 300 | 400 | 500 | 600 | 700 | 800 | |

|---|---|---|---|---|---|---|---|---|---|

| 1.0 mm | 36,10 | 29,50 | 25,90 | 20,80 | 16,90 | 13,00 | 8,10 | 3,40 | 0,50 |

| 2-0.9 mm | 49,60 | 42,10 | 34,40 | 24,70 | 17,00 | 11,60 | 7,20 | 3,30 | 0,50 |

The matching documentation for this product is available in this section.

| Documents | Language |

|---|---|

| Serbian | |

| Serbian |

The documentation is also fully available in English.

| Documents | Language |

|---|---|

| English | |

| English | |

| English |

The matching software for this product is available in this section.

| Software | Language |

|---|---|

| English | |

| English |

.jpg)

Near-Field Communication (NFC)

.jpg)

Networking in Industry 4.0 Systems

.jpg)

Automatic Air Saving Function

.jpg)

Integrated Electronic Sub-Bus System

Eco-Nozzle Technology

IMG1:

Connection of intelligent field devices (sensors and actuators)

Direct connection to the controller via only one data line

Connection of digital field devices (sensors)

Up to 4 expansion modules with 4 ports each (M12-5 socket)

Ejector discs with bistable suction valve increase process reliability

If the actuator voltage fails, the ejector remains in the last active state

Valve requires only a short voltage pulse for switching

IMG2:

(1) Connection of SCTSI via IO-Link master

(2) Connection SCTSi via Profinet / EtherCAT / Ethernet/IP

| Communication | Ethercat |

| Number of ejectors | 4 |

| SCPSt 15 G02 NO | |

| SCTSi-ECT-4-AB-4C7A-00 |

| Communication | Ethercat |

| Number of ejectors | 4 |

| SCPSt 15 G02 NC | |

| SCTSi-ECT-4-AB-4C7N-00 |

| Communication | Ethercat |

| Number of ejectors | 8 |

| SCTSi 15 G02 NO | |

| SCTSi-ECT-8-AB-8C7A-00 |

| Communication | Ethercat |

| Number of ejectors | 8 |

| SCTSi 15 G02 NC | |

| SCTSi-ECT-8-AB-8C7N-00 |

| Communication | EtherNet/IP |

| Number of ejectors | 4 |

| SCPSt 15 G02 NO | |

| SCTSi-EIP-4-AB-4C7A-00 |

| Communication | EtherNet/IP |

| Number of ejectors | 4 |

| SCPSt 15 G02 NC | |

| SCTSi-EIP-4-AB-4C7N-00 |

| Communication | EtherNet/IP |

| Number of ejectors | 8 |

| SCTSi 15 G02 NO | |

| SCTSi-EIP-8-AB-8C7A-00 |

| Communication | EtherNet/IP |

| Number of ejectors | 8 |

| SCTSi 15 G02 NC | |

| SCTSi-EIP-8-AB-8C7N-00 |

| Communication | Profinet |

| Number of ejectors | 4 |

| SCPSt 15 G02 NO | |

| SCTSi-PNT-4-AB-4C7A-00 |

| Communication | Profinet |

| Number of ejectors | 4 |

| SCPSt 15 G02 NC | |

| SCTSi-PNT-4-AB-4C7N-00 |

| Communication | Profinet |

| Number of ejectors | 8 |

| SCTSi 15 G02 NO | |

| SCTSi-PNT-8-AB-8C7A-00 |

| Communication | Profinet |

| Number of ejectors | 8 |

| SCTSi 15 G02 NC | |

| SCTSi-PNT-8-AB-8C7N-00 |