From CAD file to digitally designed gripping solution: Schmalz automates sheet metal handling

The Digital Engineering Service from Schmalz creates a tailored gripping solution from CAD data in the shortest possible time – without any manual calculations.

Schmalz's presence at Blechexpo 2025 will be characterized by a trade show innovation – and it has the potential to revolutionize engineering processes. With the Digital Engineering Service, digital designs of tailored gripping solutions are created automatically – in a way that was simply not possible before by using conventional methods and manual analysis due to sheer volume of data and time it would take. With just a few clicks, users receive a reliable design that is precisely tailored to their workpieces. The basis is CAD data or simple parameter entries. The software analyses geometries, centres of gravity and possible gripping points and creates an optimized model. The benefit: the engineering process is up to 80 % faster – one day instead of one week engineering time. The result is an economical, scalable and process-reliable solution that conserves resources because it does not require any superfluous components.

Smart gripping, automated loading and unloading

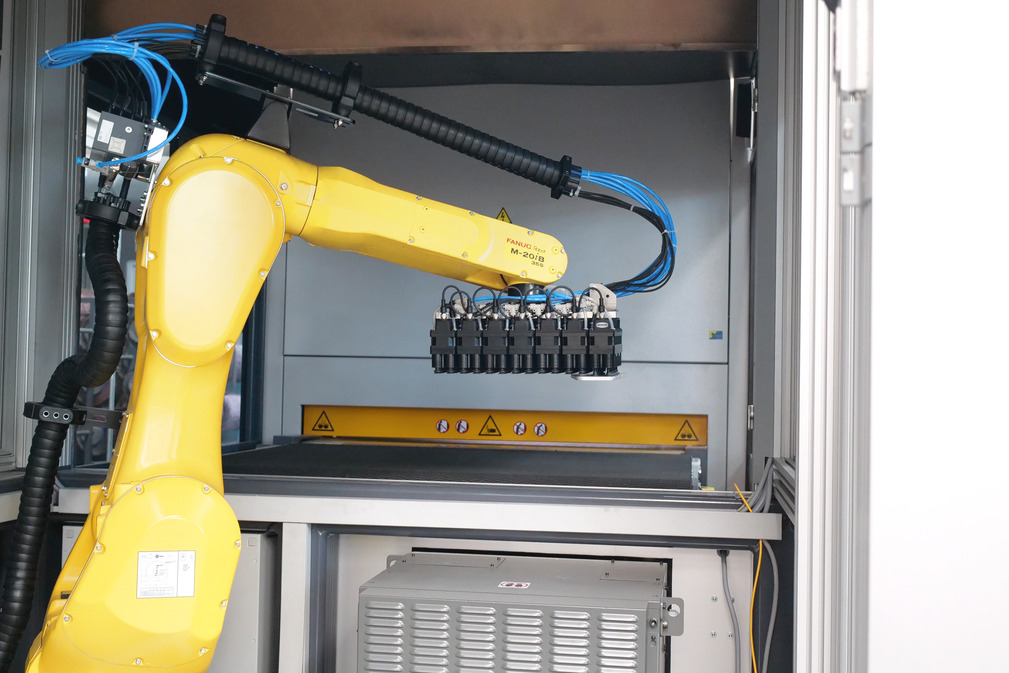

Schmalz will also be presenting the Solution Kit ivOS Sheet Metal at the trade show. This combines 3D vision sensors, the right gripping technology and artificial intelligence (AI) to create a plug-and-work solution for handling sheet metal – increasing productivity in partial automated processes by up to 50 percent. With the next step towards full automation, increases of up to 90 percent are even possible. The system automatically recognizes different or unknown workpiece geometries without the need for programming or manual intervention. The software segments the workpieces to be gripped and independently selects the strategy and control of the individual suction cups. It takes over the entire process planning, calculates the best stopping point and controls the robot collision-free until it reaches its destination. If the requirements in production change, the software optimizes part handling and continuously expands the range of recognized workpieces and executable processes. This provides operations with a future-proof system.

Moving workpieces with different geometries reliably? The matrix area gripper FMG, which can also be seen in Stuttgart, can do just that. The modular system automates the handling of different workpiece shapes and dimensions. The gripper demonstrates its flexibility particularly in high-mix, low-volume processes. It picks up individual workpieces from complete storages and reliably grips even very thin parts. This is made possible by individually controllable suction cups in each module; several modules can be blocked together to form a large area gripper. Even if the actuator voltage is lost, the matrix area gripper FMG holds the workpieces reliably.

Ergonomic solutions for moving heavy loads

With the crane gantry KBG and the vacuum lifting device VacuMaster Comfort, Schmalz is focusing on the manual handling of large sheet metal, for example when loading CNC machines. Using a chain hoist suspended from the modular gantry, a single person can lift, rotate or swivel loads weighing up to 750 kilograms by up to 180 degrees as required. A controlled vacuum generator minimizes energy consumption and enables even handling of large and flat workpieces.

Another innovation in sheet metal handling is the oval bellows suction cup SAOXB. This adapts perfectly to curved, elongated workpieces – even on oily surfaces and at fast cycle times. Its special structured friction surface and high lifting capacity ensure safe holding force during fast movements and complex contours.

Intelligent control in mini format

Also on display at the trade show: A clever solution for the automated handling of airtight and slightly porous materials. The mini compact terminal SCTMi offers up to 16 SCPMi ejectors suitable for mounting on blocks and communicates via common interfaces such as IO-Link, PROFINET, EtherCAT or EtherNet/IP. A variant with interlocked valves divides a central vacuum generator into different suction zones. The special feature: The SCTMi models already have an integrated power blow-off function as standard. Thanks to their compact dimensions and low weight, they are flexible to install and can withstand high accelerations on the axis.

Schmalz at the Blechexpo: Hall 1, Stand 1110

The Solution Kit ivOS Sheet Metal enables AI-controlled sheet metal handling for changing workpieces without complex adaptations.

The flexible matrix area gripper FMG can reliably move flat and very thin workpieces.

Up to 750 kilograms: The vacuum lifting device VacuMaster Comfort enables energy-efficient and even handling of heavy parts.

The mini compact terminal SCTMi is a clever solution for the automated handling of airtight and slightly porous materials.

Pressekontakt

Für Rückfragen steht Ihnen das Schmalz Presseteam gerne zur Verfügung.