Schmalz at FACHPACK: These grippers can handle anything

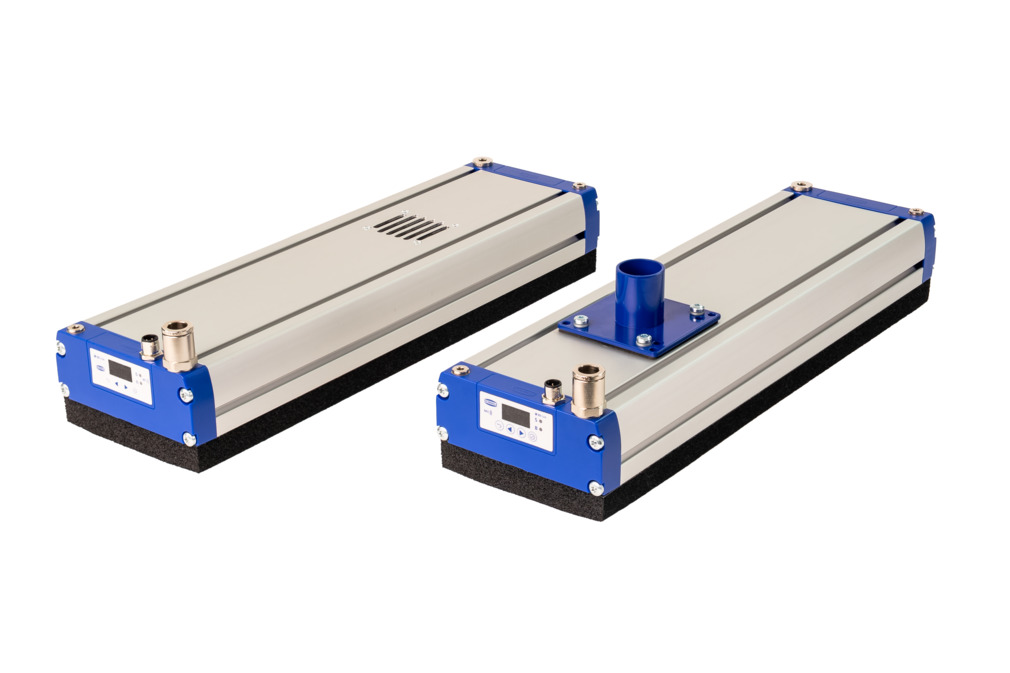

The area gripping systems FA-X and FA-M save up to 80 percent energy thanks to smart technology and an efficient nozzle system.

The new vacuum area gripping systems FA-X / FA-M move whatever comes their way - for example cardboard boxes, bags and cans. Thanks to integrated or external vacuum generation, they are flexible to use. The smart variant delivers process data directly to the display or via an app. A nozzle system saves up to 80 percent energy and the sealing foam can be changed quickly. Applications achieve maximum efficiency with minimum consumption - optimized for sustainable processes and versatile material handling.

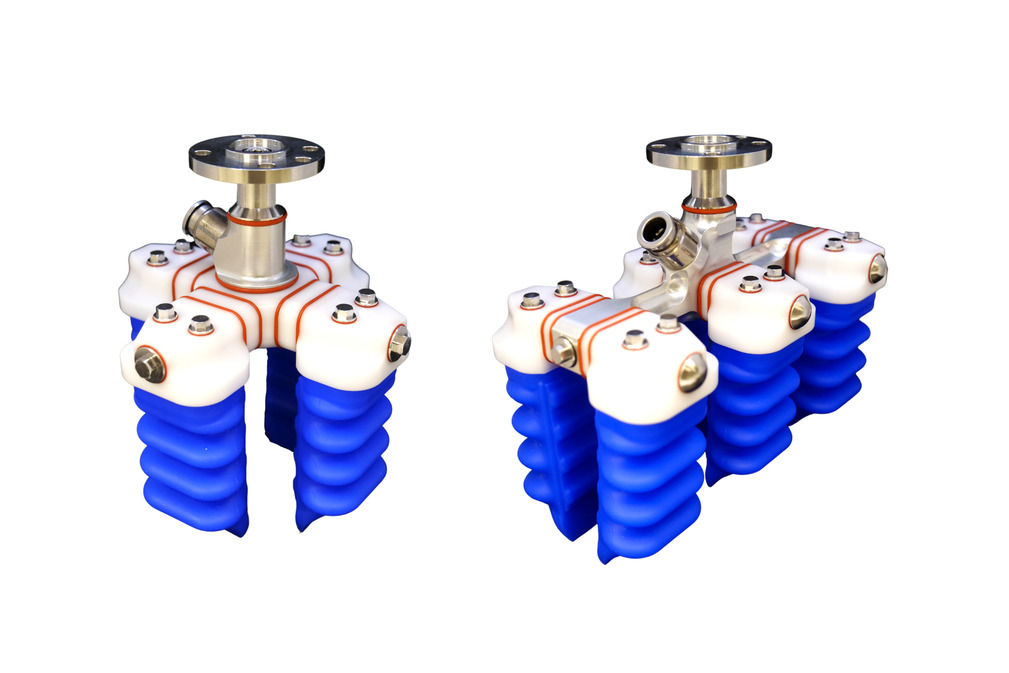

Whether flat, round or misshapen: the finger gripper mGrip from Schmalz reliably grips delicate food products - from croissants to chicken thighs. Its soft, modular fingers grip tirelessly. The system is lightweight, meets hygienic design requirements, adapts to cobots and is easy to configure. This makes it suitable for fast pick-and-place operations in the food industry and wherever sensitive products need to be moved automatically.

Stable gripping, flexible palletizing

The underfeed gripper allows open boxes and fragile ready-to-shelf packaging to be handled safely - without slipping or deforming. For example, it handles single-variety end-of-line palletizing after filling, as well as mixed palletizing tasks in logistics centers and in retail. Schmalz combines vacuum technology with a supporting sheet. Thanks to its load capacity of 25 kilograms, the underfeed gripper is suitable for many requirements and provides safe horizontal and vertical gripping.

Industrial communication without cable clutter

IO-Link Wireless avoids rigid cabling in production. The wireless solution transmits data contactlessly between sensors, actuators and controls - reliably, without interference and without complex mounting. The system shows its strengths in robotics in particular: flexible grippers, many axes, tight installation spaces. Schmalz supports the protocol with numerous solutions. This saves applications time, space and money and allows retrofitting at any time without conversion.

Lifting without effort

With the vacuum tube lifter JumboFlex, applications can ergonomically handle loads weighing up to 50 kilograms. Thanks to the intuitive grip and fast cycle time, they can move bags, crates or cardboard boxes effortlessly. The new generation relies on modular grippers and a high cycle frequency. This makes it suitable for logistics, production and packaging.

For loads up to 300 kilograms, the tube lifter JumboErgo impresses with its operator handle. This imitates a motorcycle throttle grip and ensures sensitive control. With its multiple suction cups, the vacuum tube lifter also adapts to unstable workpieces. The compact design, the fast 90-degree rotation function and the modular gripper system make it an efficient solution for production and logistics.

Schmalz at Fachpack: Hall 7, Booth 571

The finger gripper mGrip from Schmalz grips sensitive food products hygienically, flexibly and reliably - with soft, pneumatic fingers.

The vacuum tube lifter JumboErgo is suitable for many tasks - thanks to its compact design, modular grippers and precise control.

Media contact

The Schmalz press team will be happy to answer any questions you may have.