Schmalz at HOLZ-HANDWERK: Ergonomics in a handy format

Thanks to VacuMaster Wood, employees can handle even large sheets precisely and effortlessly.

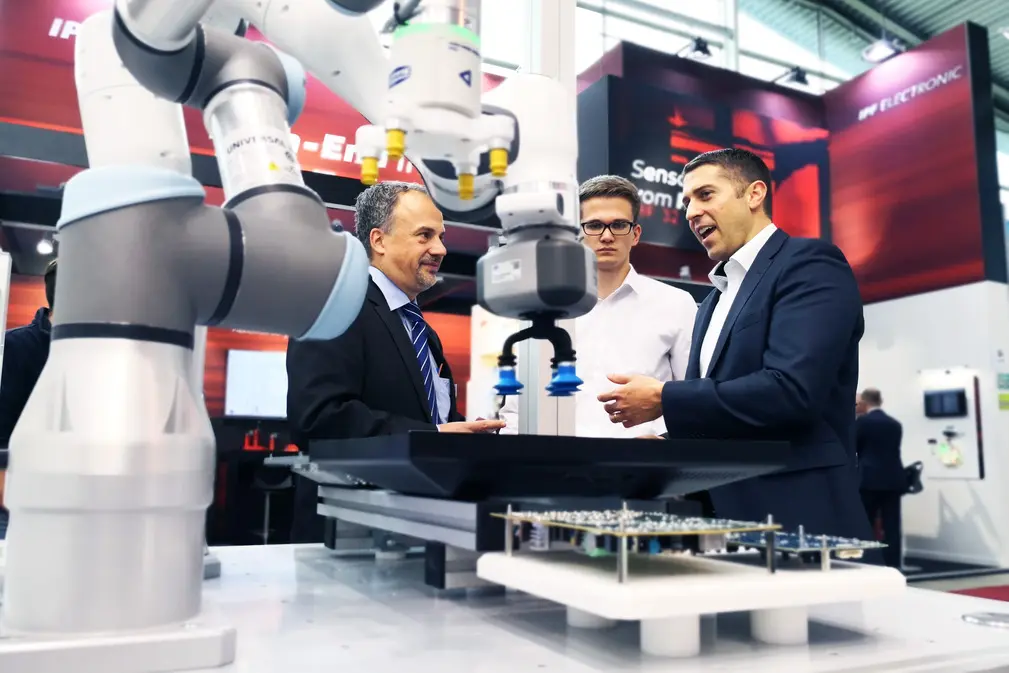

Woodworking companies today organize their processes under demanding conditions. Workpieces are becoming larger and more varied, and production cycles are becoming more compressed. At the same time, the health of employees is becoming an even greater focus. If you want to work economically, you need technology that handles materials safely and supports people. Schmalz brings ergonomics directly to the workplace. The aim is to measurably reduce physical strain so that skilled workers remain productive in the long term. Vacuum handling and supplementary body-worn assistance systems relieve strain on the back, shoulders and joints, while processes remain stable. This reduces downtime and gives operations planning security.

The highlight at the booth is a manual handling device that Schmalz is presenting to the public for the first time at HOLZ-HANDWERK. The solution supports ergonomic working methods, can be operated intuitively and - unlike the well-known tube lifters and crane systems - is easy to take with you. Schmalz is thus addressing core processes in production and order picking. Visitors to the trade fair can see for themselves and test the new lifting aid in practical use directly at the stand.

VacuMaster Wood: Safe lifting, precise guidance

The VacuMaster Wood makes manual handling of sheets and components in wood working easier, as it absorbs their weight and thus significantly reduces the load. Applications can also position large workpieces precisely and effortlessly. This speeds up work processes because employees can move and align products in a single step. The ergonomically designed lifting solution grips porous and coated components equally reliably.

Exoskeletons provide support where it counts

With exoskeletons, Schmalz supplements ergonomic handling with body-worn assistance systems. The MATE UTA upper body exoskeleton relieves strain on the shoulders and arms when working above chest height. The MATE UBA forward bend exoskeleton supports the lower back when bending forward frequently. Both systems are mechanical and do not require a power supply. For woodworking companies, this means less fatigue, a lower risk of injury and a staff that can achieve their tasks in good health for longer.

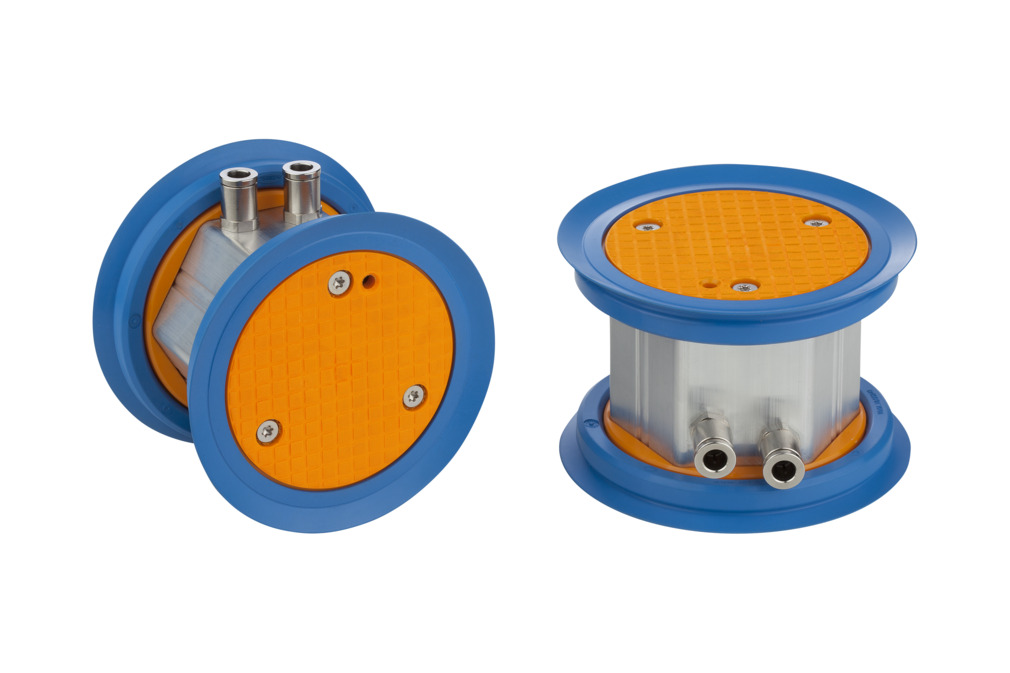

Flexible clamping systems in CNC wood and glass processing

With the VCMC-HZ horizontal clamp, Schmalz is presenting a new clamping system for console tables, which will also be on show for the first time at the trade show. A fixed stop and a movable clamping module clamp workpieces horizontally. This creates more space for the workpiece and greater freedom for the process. The two-part design allows free dimensions. Four defined clamping heights cover different material thicknesses. Reduced interfering contours keep the machining area clear. Variants with compressed air or mechanical drive facilitate integration into 1-circuit and 2-circuit systems. Applications significantly lower set-up times and double throughput, as the double-sided stop enables parallel clamping.

Schmalz has the VCBL-GL vacuum block for handling glass. The friction plate and sealing are specially designed for CNC glass processing centers. Thanks to a large selection of dimensions, the vacuum blocks reliably hold workpieces of different geometries.

Thinking outside the box

Binar Handling, part of the Schmalz Group, will be exhibiting a VacuMaster Window and also the new handling device at the parallel FENSTERBAU FRONTALE trade fair in Hall 3, Stand 430. The systems supplement the ergonomic approach to window construction.

Schmalz at the HOLZ-HANDWERK: Hall 9, Stand 210

The MATE UBA forward bend exoskeleton provides targeted relief for the lower back during lifting activities, enabling healthy and efficient work.

The VCMC-HZ horizontal clamp for console tables has a fixed stop and a movable clamping module for maximum flexibility.

Media contact

The Schmalz press team will be happy to answer any questions you may have.