Schmalz at LogiMAT: Effortless gripping and lifting with a system

The MATE UBA forward bend exoskeleton relieves pressure on the bottom of the back during lifting and bending movements and supports physically demanding work.

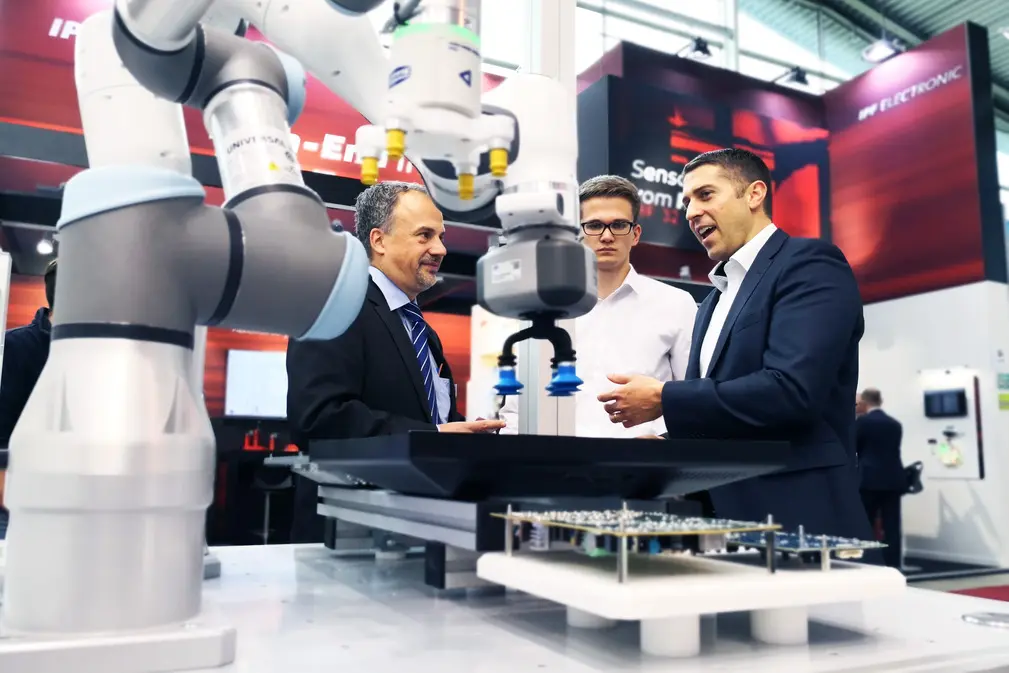

Many operations in storage and shipping are constantly repeated. This is precisely where Schmalz comes in with its strength-saving handling systems. These include vacuum lifters, balancers and exoskeletons. These solutions provide support where people are lifting heavy loads or working overhead. In this way, companies combine ergonomic workstations with economically stable processes.

Exoskeletons act like a mechanical support structure that employees wear on their bodies. They relieve the strain on certain muscle groups during frequent lifting or carrying. The MATE UTA upper body exoskeleton and the MATE UBA forward bend exoskeleton adapt to typical logistics movements and reduce physical strain.

With the Quick-Lift-Arm QLA from Binar Handling, part of the Schmalz Group, the vacuum specialist is adding another solution to its portfolio. Because it guides the loads almost weightlessly via a smart hoist, employees position goods sensitively, even with frequent changes of direction in confined spaces.

Guide tube lifters precisely and operate them easily

The JumboFlex vacuum tube lifter has been redesigned. Schmalz has optimized the operation so that skilled workers, regardless of hand size, have a safe grip and can guide loads precisely. This makes the daily lifting of cardboard boxes or bags easier and noticeably improves ergonomics. Two intuitive operating buttons release the single-button control. This allows applications to lift and lower loads intuitively, so that even new employees can move the tube lifter precisely. Thanks to the new change mechanism, the grippers can be inserted effortlessly and replaced in a single movement - making gripper changes much faster.

A new manual handling device is celebrating its premiere at LogiMAT: it is easy to operate and easy to take with you. Unlike classic tube lifters or crane systems, the solution remains mobile and flexible. This makes ergonomic lifting possible even where logistics processes are constantly on the move. Details are not yet being revealed, but will be shown publicly for the first time at the trade show.

Automation that requires little space

Schmalz has intelligent and space-saving solutions for automated applications, because every centimeter counts in modern logistics systems. The SCPL compact ejectors generate vacuum directly at the gripper. This allows applications to achieve a suction rate of 290 to 1,140 liters per minute with optimized energy consumption. The new SCPLi variant has smart functions: Thanks to the integrated IO-Link interface, relevant process data is fed into the control system. The handling process is thus monitored and optimized in an efficient and targeted manner.

The SCTMi mini compact terminal is extremely compact and lightweight. This makes it easy to integrate into fully automated handling and production systems. Short evacuation times and low energy consumption support fast cycle times and great efficiency in storage. The special feature: Applications can move different parts simultaneously with just one vacuum system.

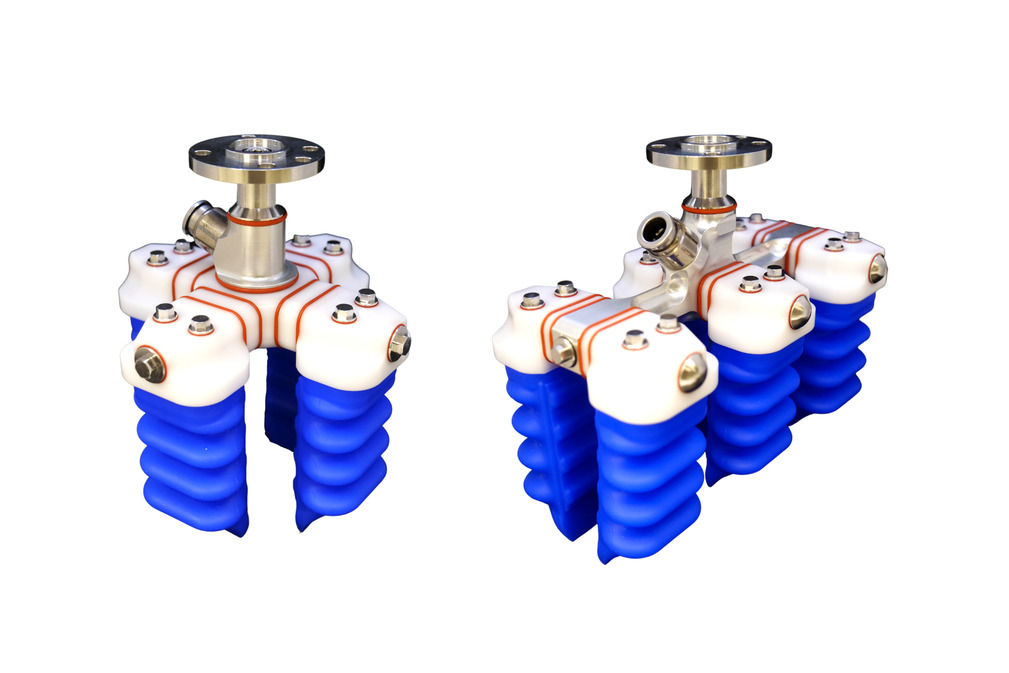

With the finger gripper mGrip, Schmalz offers a solution for anyone who wants to handle sensitive products such as vegetables, baked goods or meat in an automated and safe manner. The pneumatic fingers adapt more flexibly to the load than mechanical gripping systems. Thanks to its hygienic design and closed pneumatic circuit, the finger gripper mGrip is suitable for direct handling of food products and can be cleaned without disassembly.

Schmalz at the LogiMAT: Hall 7, Stand C05

Two operating buttons replace the single-button control on the JumboFlex, allowing users to lift, lower and guide loads intuitively and precisely.

The pneumatic finger gripper mGrip moves sensitive workpieces particularly sensitively and is easy to control.

The SCTMi mini compact terminal makes it possible to handle different parts simultaneously with just one system. It bundles several vacuum generators into one compact unit.

Media contact

The Schmalz press team will be happy to answer any questions you may have.