Schmalz at LogiMAT: gripping and lifting at its best

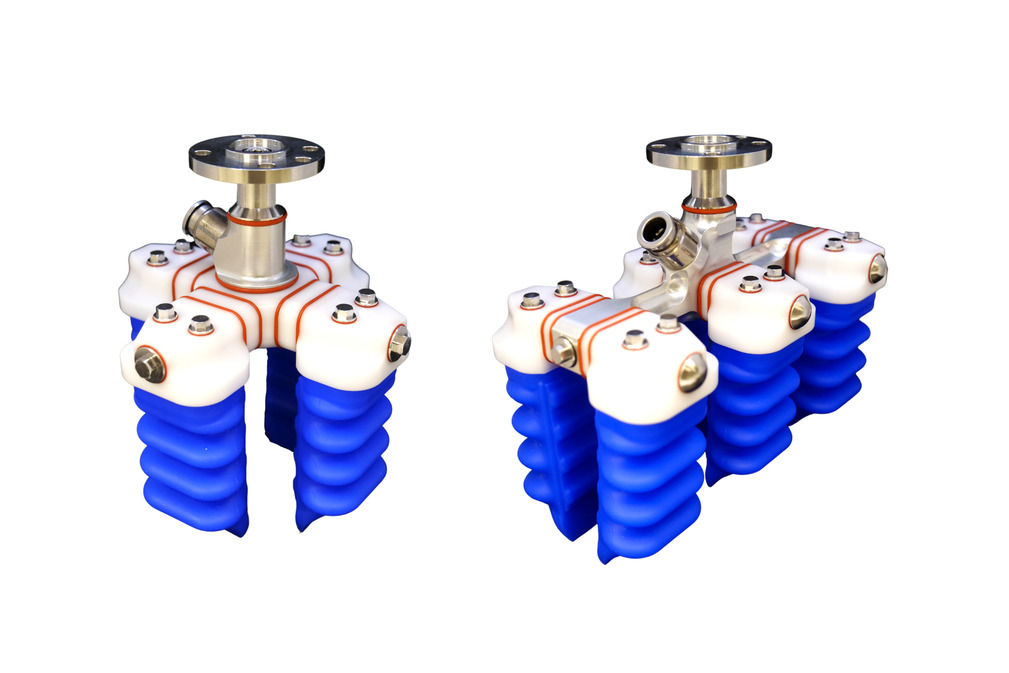

The sack gripper PSSG is a real lightweight and impresses above all with its lengthy service life.

New technologies for warehousing, material flow, transportation and robotics will be the focus of LogiMAT - the international trade fair for intra-logistic solutions and process management - in March. Vacuum expert Schmalz will be showcasing several product highlights at its booth.

Flexible, strong and safe grip

The matrix area gripper FMG has a compact and modular design. It is ideal for gripping flat and predominantly air-tight workpieces in various shapes and dimensions. It can also safely pick up and place complete product layers and very thin components. This allows users to easily automate high-mix-low-volume processes, for example in pick-and-place applications. Additional modules can be supplemented as required.

Another highlight is the gripper FQE-V, which Schmalz has designed for handling workpieces in automation technology. The modular, freely scalable system can be used to safely handle workpieces of different sizes and shapes. Thanks to smart design tools, applications benefit from particularly fast project planning of grippers in batch size 1.

The finger gripper mGrip in hygienic design meets the highest cleanliness standards. Thanks to its flexibility and adaptability, it can pick up sensitive objects such as baked goods precisely and gently. It is ideal for automated packaging processes, for example for picking small items into nets or bags. The bin-picker SBPG can also be seen at the booth. This helper for autonomous bin picking enables components to be removed from bins and thus optimizes the material flow in production.

The sack gripper PSSG is a strong lightweight with a special feature: the robust sealing lip guarantees a very long service life. Schmalz has developed it specially for handling bags; it moves heavy loads safely and efficiently. The combination of vacuum technology and an intelligent gripping mechanism makes the PSSG an optimal solution for logistics centers and production facilities.

Proven improvements

The JumboFlex has been the first choice for many years when it comes to moving workpieces weighing up to 50 kilograms. Schmalz proves that there is always room for improvement with the redesign of the vacuum tube lifter. It is now even more intuitive to use and ergonomically designed - the handle fits perfectly in every hand. Its flexible handling ensures optimal use in modern production. Visitors can experience the versatility of the JumboFlex live in various applications at the booth.

Schmalz at the LogiMAT: Hall 7, Booth C05

Thanks to its modular design, the matrix area gripper FMG can grip almost any geometry with process reliability.

The optimized JumboFlex is suitable for many different hands thanks to its ergonomic design.

The finger gripper mGrip in hygienic design can be cleaned without disassembly (CIP).

The Rope Balancer NEO 30 reacts directly to the worker's hand movement and thus supports the lifting and lowering of loads weighing up to 30 kilograms.

Media contact

The Schmalz press team will be happy to answer any questions you may have.