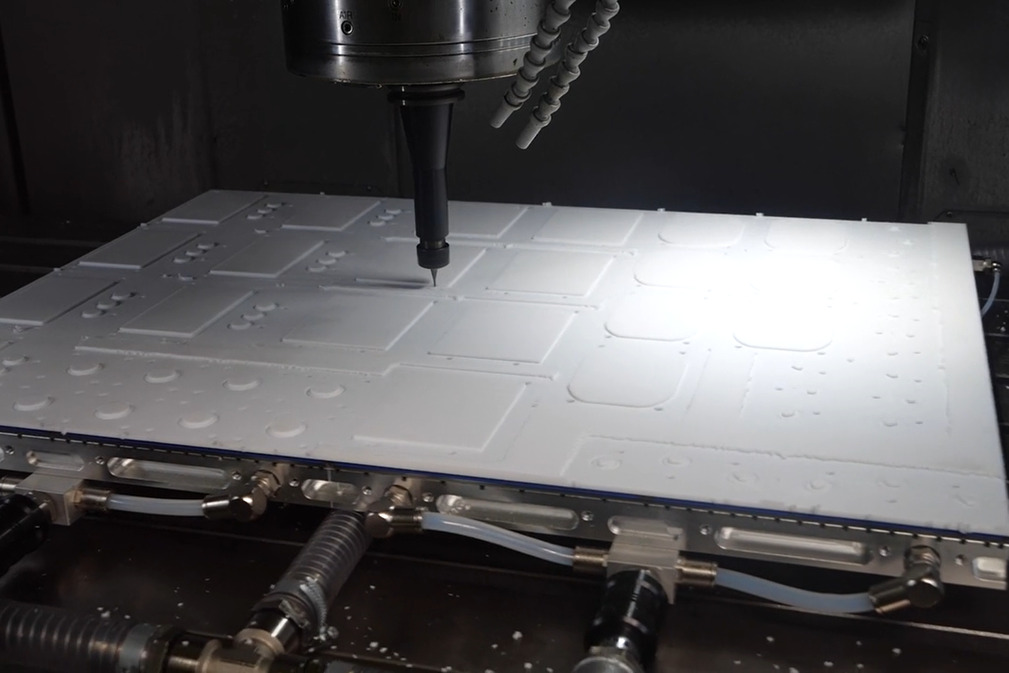

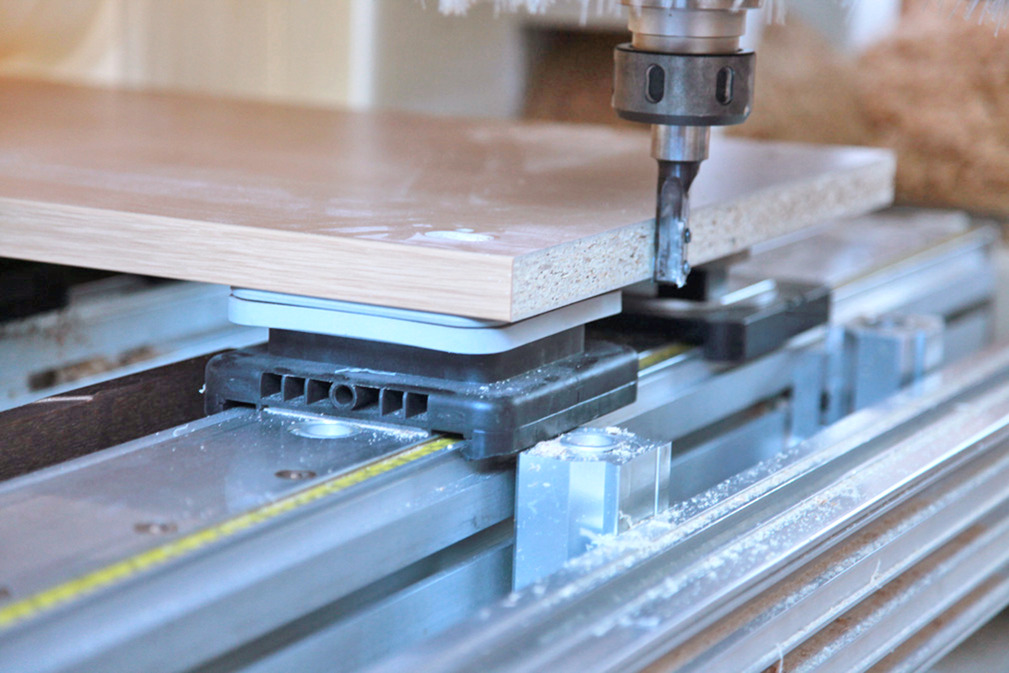

- Vacuum clamping technology for CNC machining of wooden workpieces

- Solutions for console table, grid table and flat table systems

- Clamping equipment for both narrow workpieces and workpieces made from solid wood

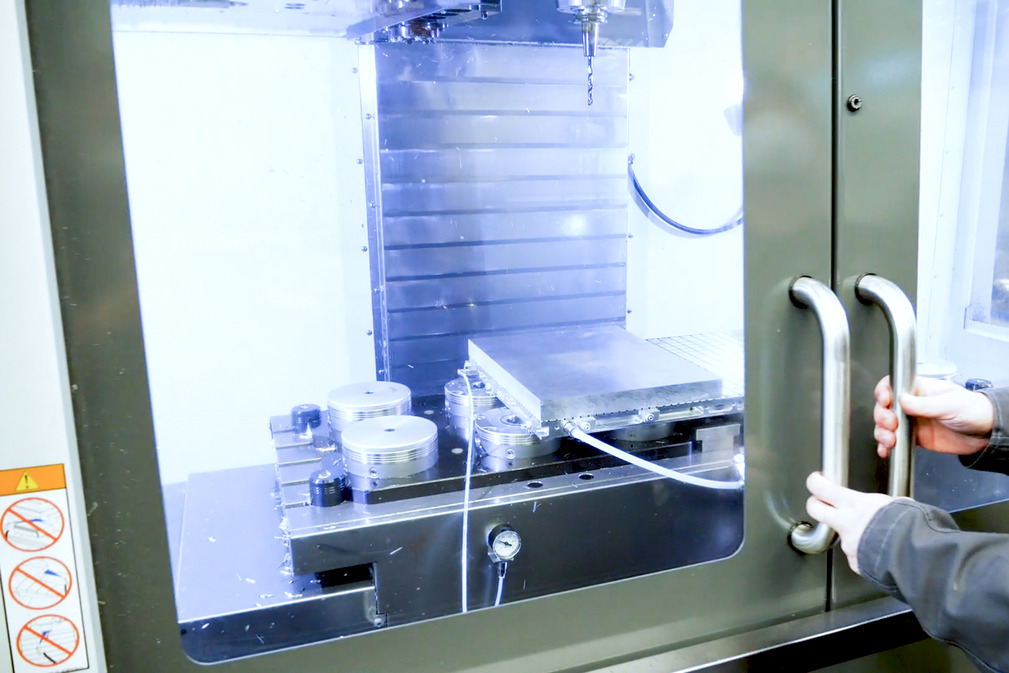

- Clamping solutions for modernizing CNC machining centers

Vacuum Clamping Technology

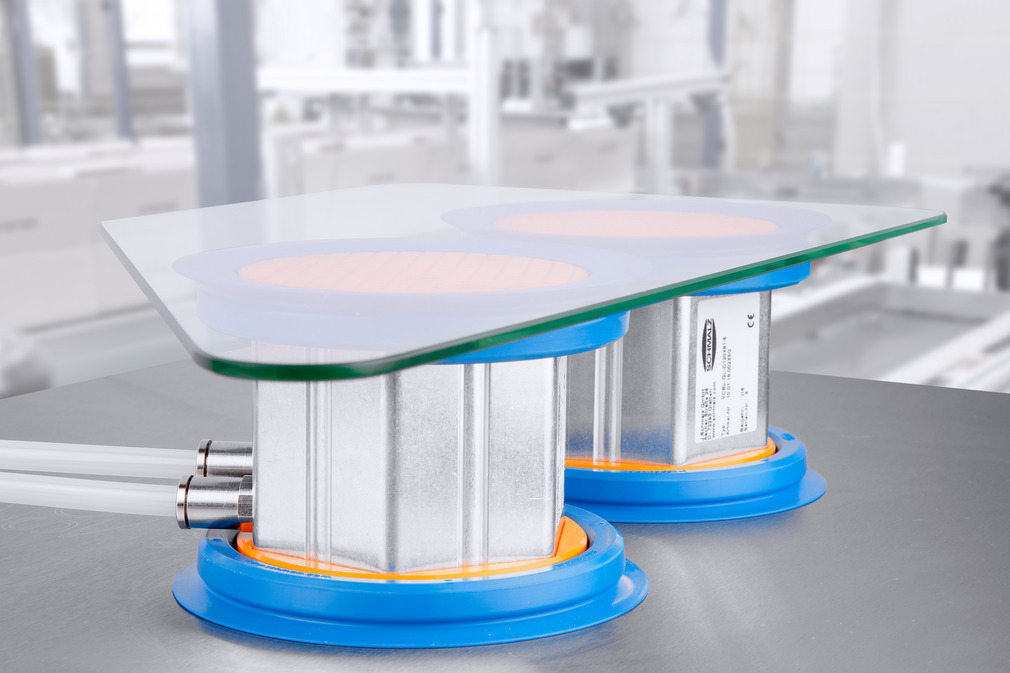

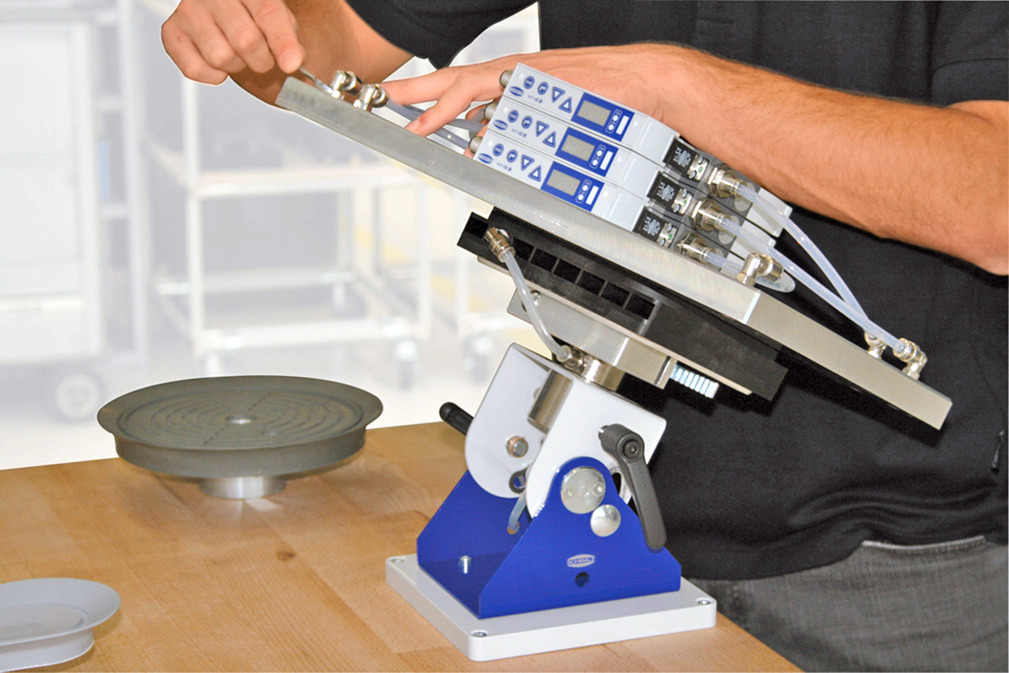

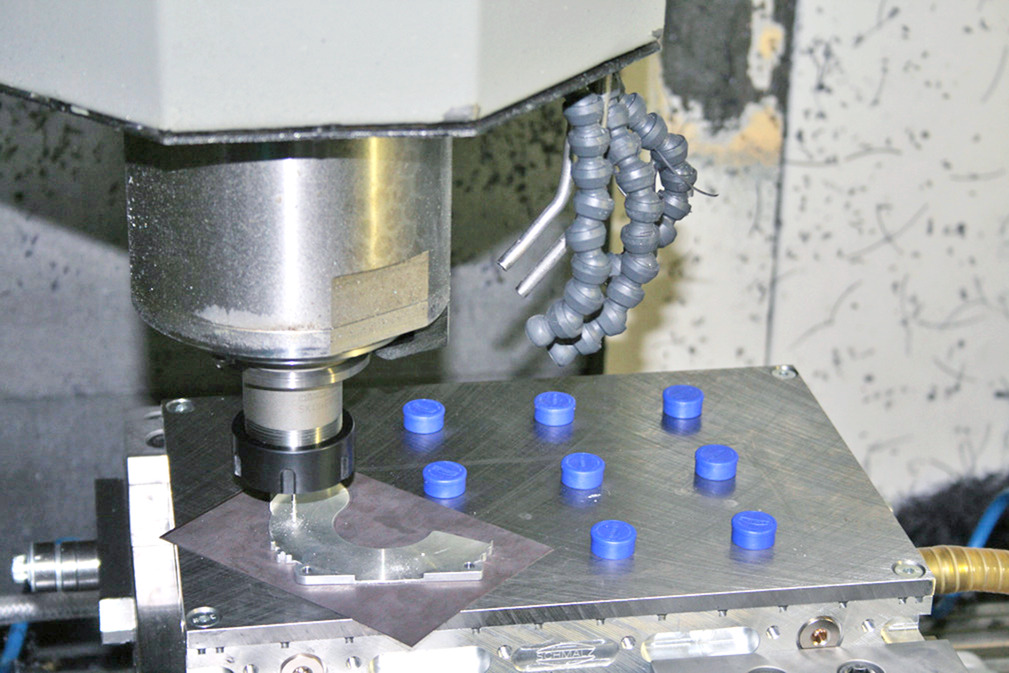

Before a workpiece can be machined reliably - for example, drilling, milling or grinding - it must always be clamped, i.e. fixed with dimensional accuracy. Clamping with vacuum offers several advantages over other clamping methods: fast, precise, damage-free and low-distortion fixing, high holding force and five-sided machining. In addition, thin and elastic materials can also be fixed.

The clamping technology program from Schmalz includes solutions for wood, glass, plastics and metal machining.

SCHUNK – Your partner for vacuum automation in Sweden

In Sweden, our partner SCHUNK Intec AB distributes and services our vacuum automation products – from components and gripping systems to vacuum clamping technology. SCHUNK offers you the right solution for your production.

Videos

Discover application examples of the product in various industries - user-friendly, informative and practical.

No suitable videos found? Then take a look at our media center.

Products

- Vacuum clamping technology for CNC machining of glass workpieces

- For flexible and efficient production processes

- Wear-resistant friction pads for high precision

- Wide range of flexible and powerful clamping equipment for low-distortion clamping of workpieces using vacuum

- Specialized vacuum generators ensure efficient and process-reliable vacuum supply

- The ideal supplement to conventional clamping technology on CNC machining centers

- Vacuum clamping technology for securely clamping workpieces with free-form surfaces with minimum warping

- Used in laser and milling processes in the fiber composite industry and in applications with metal, plastics or wood

- Powerful vacuum systems for large CNC processing machines

- Compact pumps for flexible use