Eco Power for a Better Future

Discover how the new Eco functions of our Vacuum Tube Lifters help you save energy and boost efficiency.

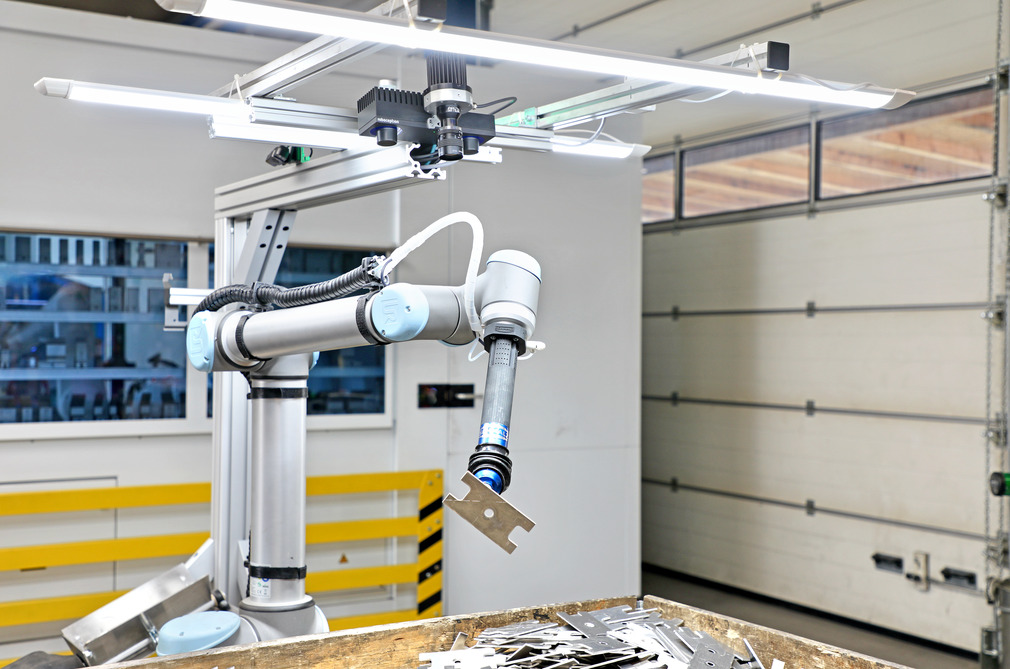

With Schmalz products, you boost your automated processes and relieve your employees of heavy physical work: smart, efficient and sustainable all around.

We know your industry, too. Whether automotive, food, logistics or electronics. Schmalz offers you the right solution for various applications. You can find detailed information about the solutions on the respective industry pages or contact us directly for a personal consultation.

Find the right products for your application. Schmalz offers a wide range of products for automation with vacuum. Order them quickly and easily in our Online Shop.

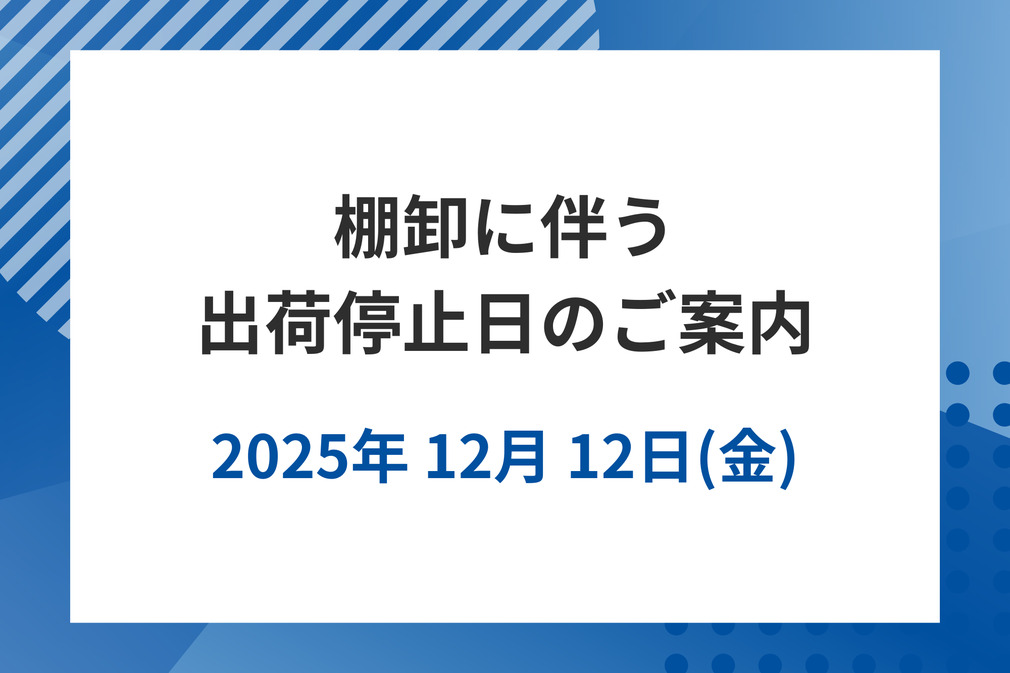

Information on the date of suspension of shipments due to inventory

Due to the implementation of inventory, shipping operations will be suspended all day on Friday, December 12, 2025.

New

Handling efficiently, working ergonomically

Anyone who manually loads or unloads dozens of containers every day knows the problem: heavy cardboard boxes, uncomfortable positions, exhausted employees. The portable conveyor systems Destuff-it™ and Restuff-it™ provide a remedy and pay for themselves faster than expected. With them, Schmalz offers a solution that achieves three goals at the same time: higher productivity, better working conditions and measurable cost benefits.

Schmalz Energy Storage receives award at the Baden-Württemberg Environmental Technology Prize

The Glatten-based company has been awarded the Baden-Württemberg Environmental Technology Prize in the "Energy Efficiency" category for its highly efficient and scalable redox flow stack. With this solution, Schmalz is bringing the most powerful stack in Europe onto the market.

Even more flexible: Schmalz expands the range of applications of the VCBL-GL vacuum block

Vacuum specialist Schmalz has further developed the VCBL-GL vacuum block. The new generation impresses with a modular design, an extensive spare parts catalog and a wider range of applications - for more flexibility and lower costs over the entire life cycle.

We combine the internationality of a globally active group of companies with the charm of a medium-sized family business. Schmalz products are used in logistics applications as well as in the automotive industry, the electronics sector or furniture production. The combination of comprehensive consulting, high innovation orientation and first-class quality ensures customers sustainable added value. Intelligent solutions from Schmalz make production and logistics processes more flexible and efficient - and at the same time fit for the advancing digitalization. Schmalz is represented in all important markets with its own locations and trading partners in around 70 countries. The family-owned company employs around 1,800 people at its German headquarters (Glatten, Black Forest) and in 30 other companies worldwide.