Lifting Technology

Lifting technology is one of the most important components in internal processes. Vacuum technology can be used to lift workpieces, deposit them at a specific position or hold them in a certain position. Schmalz offers a comprehensive range of lifting technology for both manual and automated processes. Schmalz successfully uses the vacuum medium to generate the lifting motion. Schmalz handling technology primarily consists of vacuum components vacuum gripping systems lifting devices.

Lifting Technology for Use in Any Application

Schmalz has many years of expertise in the field of vacuum technology in numerous industries. Over the years, a variety of lifting equipment has been developed to meet the requirements of a specific sector, for example the glass or automotive industry.

Lifting Technology for Automated Handling Systems

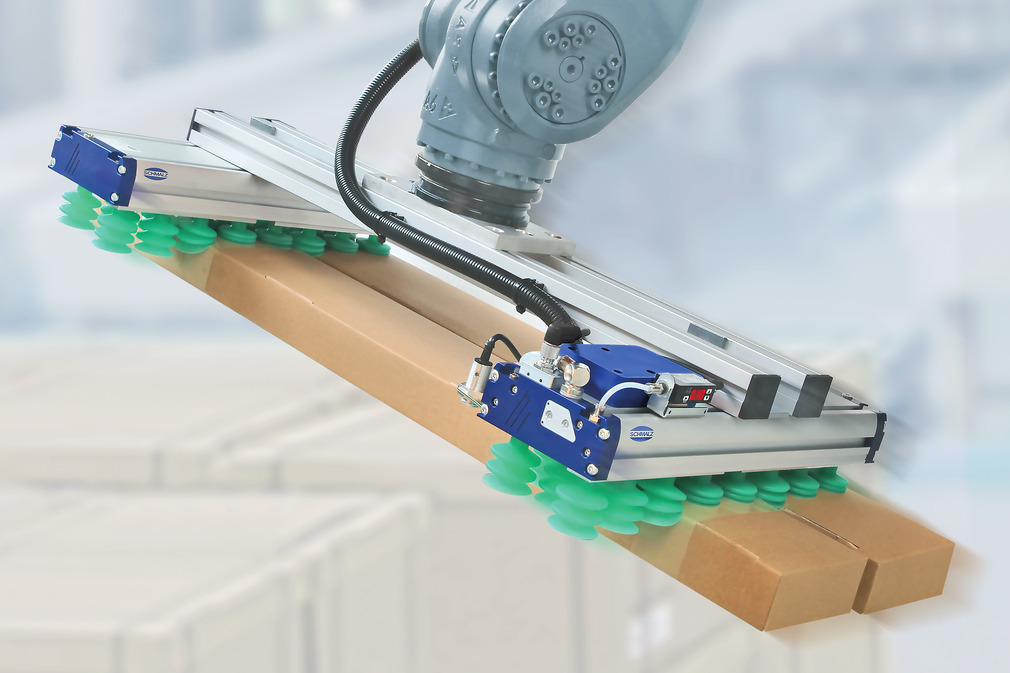

In the area of automated handling, Schmalz gripping systems reduce cycle times and use intelligent technology to reduce operating costs. Vacuum technology for automated handling comprises the following systems at Schmalz: the area gripping systems FXP/FMP have enormous suction power and can handle even heavy workpieces quickly. The layer gripping system SPZ is particularly well-suited to use in warehouse and intralogistics applications: These grippers use a combination of vacuum technology together with a global vacuum and mechanical grippers, enabling entire product layers or pallets to be gripped. The vacuum suction spider SSP is configured as end-of-arm tooling to meet specific customer requirements and thus ensures the best possible lifting result. For pick and place applications with Delta, SCARA or articulated robots, Schmalz has developed a new lifting technology with the vacuum end effector VEE. The innovative modular system offers unique flexibility, since the number and position of vacuum suction cups can be adjusted. the innovative VEE technologys designed to safely handle high-speed applications.

Lifting Technology for Manual Handling Systems

In the field of manual lifting technology for heavy loads, Schmalz vacuum lifters,column-mounted jib cranes and crane systems are an ergonomic and fatigue-free solution. Even when handling lighter loads, the moving mass can amount to several tons during a single shift. Schmalz handling systems make manual handling processes efficient and ergonomic. At the same time, they consistently reduce operating costs thanks to a range of innovative functions. Having consultants on hand to provide advice and an individual system design also ensures that Schmalz lifting technology is perfectly adapted to customer-requirements. Schmalz makes a distinction between two types of vacuum technology for manual handling systems: the vacuum tube lifter Jumbo allows for ergonomic handling of loads weighing up to 300 kg with high switching precision. The vacuum lifter VacuMaster can be used to move loads weighing several tons safely and with health and safety in mind. Combined with Schmalz crane systems these devices offer ready-to-connect complete systems for your handling applications. Schmalz grippers are powerful tools in all areas of manual handling.

More Information

Vacuum Technology for Automation

Automation with vacuum is a key to efficient processes. Individual components and ready-to-connect gripping systems from Schmalz are used successfully in various industries and applications.

Our manual handling solutions

Ergonomic handling made easy: Discover our solutions here.

Vacuum Technology in Practice

To meet the specific demands of various industries, we offer vacuum components and System solutions for range of different automation, handling and logistics applications.