- Move workpieces up to 300 kg quickly and easily

- Configurable lifting unit, operator handle, vacuum gripper and vacuum generator

- Lifting and lowering the load using vacuum

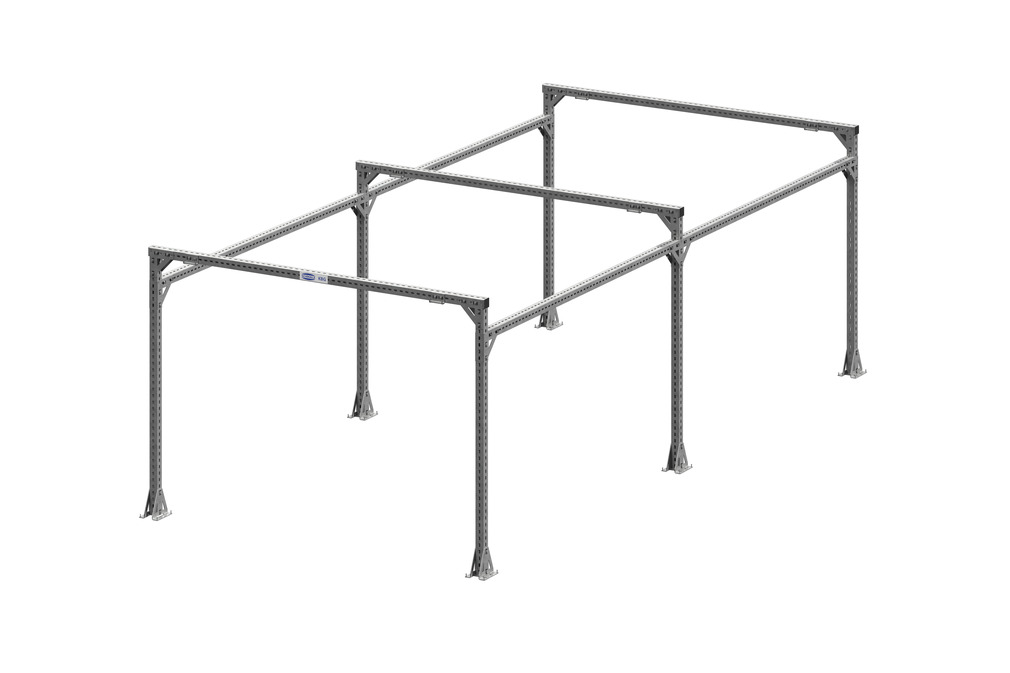

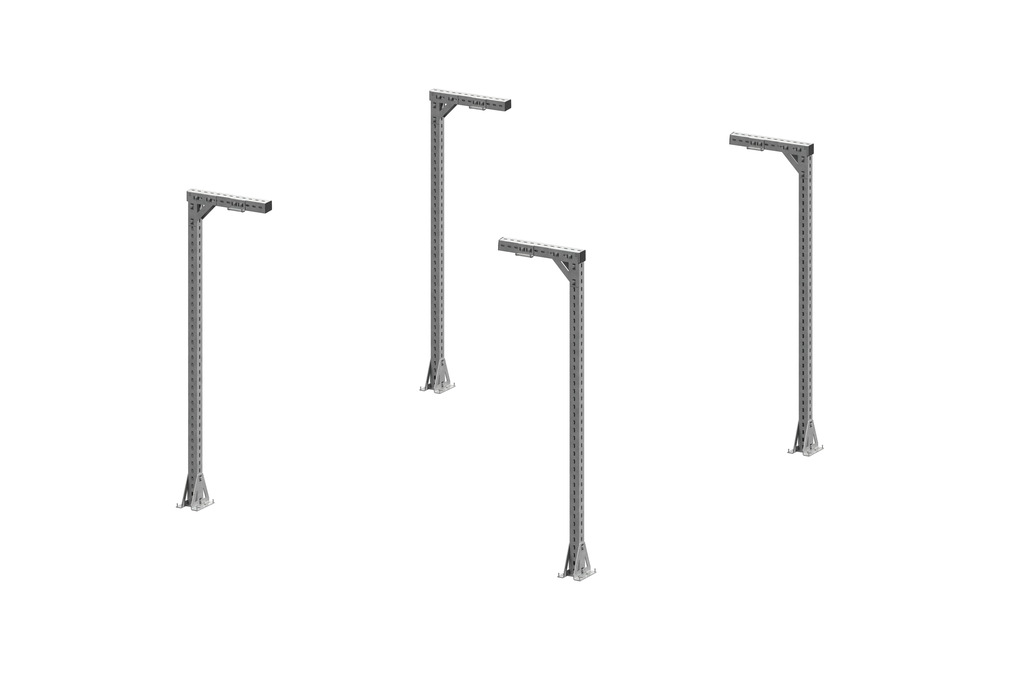

Aluminum Bridge Cranes

Schmalz aluminum overhead crane systems offer impressive low friction operation. A favorable weight-load ratio ensures that even heavy work pieces are handled effortlessly. The equal distribution of loads on all the supporting rollers prevents the transport trolleys from tilting. The modular design allows the crane system to be attached to any steel structure or other superstructure.

Ergonomic handling thanks to outstanding low-friction operation and low moving mass

Reduction of throughput times due to high working speed and positioning accuracy

Cost-efficient adaptation to individual requirements and lift capacities

Maximum safety through independent strength calculation of all load-bearing components according to the FEM method

Designed according to the latest state of the art (DIN EN 13001)

Awarded the seal of approval by Aktion Gesunder Rücken e. V.

Schmalz vacuum lifters and crane systems support the back and musculoskeletal system when lifting light and heavy loads. They reduce strain and help to make the work environment ergonomic. This is confirmed by the independent association Aktion Gesunder Rücken e. V. (AGR) with its seal of approval.

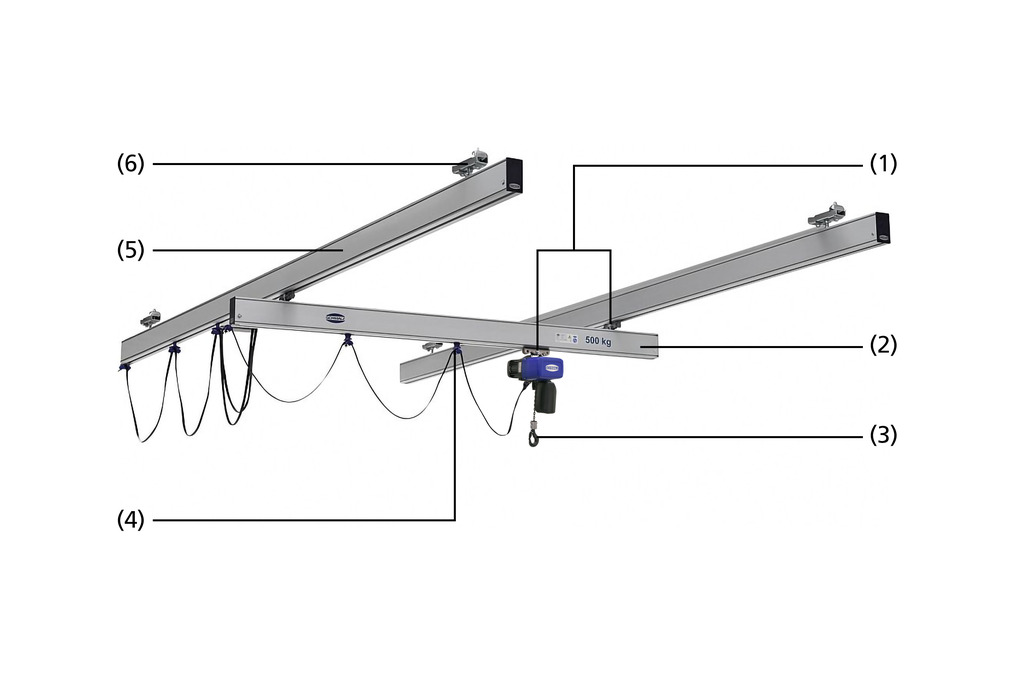

Design

- (1) Transport trolley, connection of crane bridge and hoist

- (2) Aluminum crane bridge

- (3) Chain hoist

- (4) Energy supply, trailing cable or conductor line

- (5) Aluminum crane runway, lightweight and robust, weights from 3 kg/m

Modular elements

.jpg)

Lightweight and Robust Aluminum Section

- Weight optimized extruded section with hollow chamber geometry (weight from 3 kg/m)

- Inner web for reinforced vertical support

- Material: Aluminum natural anodized (EN AW 60 63 T66)

- Five section sizes for loads weighing up to 1,200 kg

- Section lengths up to 8,000 mm can be extended as needed using rail connectors

- Dovetail for retroactive mounting of variable end stops

- Lateral grooves for connecting accessories

.jpg)

End plate

- Attractive closing off of sections

- Protection from dirt

.jpg)

Reinforcement section

- Increases range and suspension distance by up to 50% while maintaining the same maximum load

- Increases the maximum load for installed crane systems

.jpg)

Rail connector

- Positive and non positive connection of sections for crane runways or bridges larger than 8,000 mm

- Full load capacity at the interface

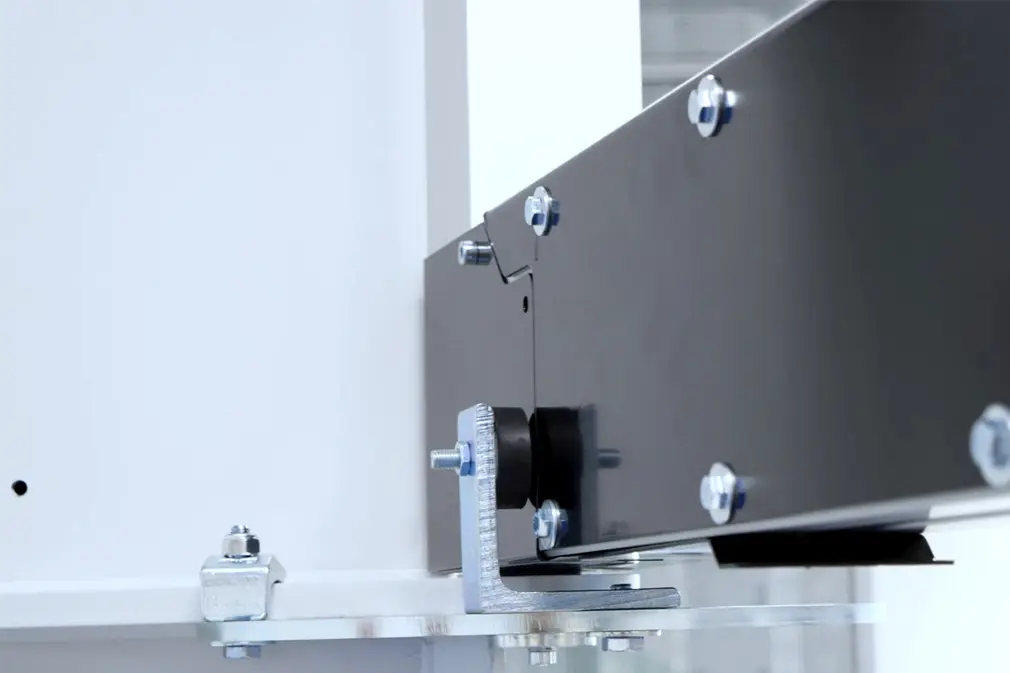

Transport Trolley with Optimal Running Performance

- Stable aluminum pressure cast construction for loads weighing up to 1,000 kg

- Only one transport trolley required to connect the crane bridge and hoist; thus less parts

- Double transport trolley for loads weighing up to 1,200 kg

- Optimal running performance thanks to large rollers made from high performance plastic

- Upward and downward forces absorbed by only six rollers

- Optimized for low ceiling heights thanks to its compact size

- Eccentric pressure rollers to compensate vertical forces in telescopic booms

.jpg)

Crane bridge suspension element

- Maximum load 2,000 kg

- Swivel mounted as standard

- Easy replacement of the joint

- 90° design for standard crane bridge; 0° design for telescopic rails

.jpg)

Fixed end stops

- Prevents transport trolleys from falling out

- Positive locking for maximum safety

- Tool free mounting

.jpg)

Variable end stops

- Easy adjustment of the crane bridge and hoist travel path

- Demarcation of several working areas and the cable storage device

- Can be mounted at a later stage

.jpg)

Antishock end stops

- Gentle stopping of transport trolleys if end stops have to be reached e.g. for dynamic applications and telescopic jibs

Distance connectors

- Stiffener for mounting rigid load and lifting axes

- Available for all section sizes

Service station

- Easy replacement of transport trolleys, particularly for long crane systems and for crane systems with several crane bridges

- Available for all section sizes

- Fully resilient depending on the section size

.jpg)

Low headroom module

- Raises crane bridge to the level of the crane runway

- Reduces the overall height of crane systems for low ceiling heights or transit roads

Spring return for telescopic jib incl. damping

- Returns telescopic jibs after reaching into difficult to access areas

- Optimal work flow thanks to the independent return of the jib

.jpg)

Safety cables

- Further secures crane bridges, crane runways and hoists by means of steel cables

.jpg)

Suspended, height-adjustable

- Most common suspension

- Compensation of height differences in the ceiling structure by up to 30 mm

.jpg)

Rigid, height-adjustable

- Absorption of upward forces for telescopes, lifting axes or manipulators

.jpg)

Rigid short 0°

- Reduction of the overall height for low ceiling heights

.jpg)

Rigid short 90°

- 90° rotated design to reduce the overall height for low ceiling heights

.jpg)

Anchor plates for concrete ceilings

- Special high-performance anchors with approval for dynamic loading

- Required concrete quality C20/C25, concrete thickness min. 200 mm

.jpg)

Clasp for wooden girders and laminated beams

- Safe mounting on wooden girders and laminated beams

.jpg)

Extension by up to 2,000 mm

- Extension of the suspension to max. 2,000 mm for high ceilings

- Diagonal brace required for stabilization

.jpg)

Diagonal suspension

- Connection for ceiling structures with inclines greater than 8°

- Diagonal brace required for stabilization

.jpg)

Conductor Line

- Wireless energy supply for electrical devices supplied in the crane such as the chain hoist or vacuum lifting device

- Profit from usable ceiling height as there are no cable storage devices or cable loops to cause interference

- Ideal for crane systems with several bridges

- Low surplus loading of the crane system thanks to lightweight plastic rails

- Easy mounting thanks to adapted suspensions and spring loaded connectors for copper contacts

.jpg)

Trailing Cable

- Most common form of energy supply via cable trolleys in the aluminum section

- Suitable for power cables (flat cables) and hoses (vacuum and compressed air)

- Easy mounting thanks to pre-assembled cable trolley

Technical Data

- Maximum dimensions: approx. 8 x 30 m

- Maximum load: approx. 1,200 kg (depending on crane girder's own weight)

- Weight of smallest crane profile: only 3,0 kg/m

| Type | Height [mm] | Weight [kg/m] | Max. lift capacity [kg] | Area moment of inertia [cm4] lx | Area moment of inertia [cm4] ly | Moment of resistance [cm3] wx | Moment of resistance [cm3] wy |

|---|---|---|---|---|---|---|---|

| SRA-100 | 100 | 3.1 | 125 | 89 | 112 | 21 | 25 |

| SRA-105 | 105 | 5.5 | 250 | 244 | 253 | 48 | 51 |

| SRA-140 | 140 | 7.8 | 500 | 384 | 651 | 92 | 77 |

| SRA-180 | 180 | 9.2 | 800 | 457 | 1,283 | 145 | 92 |

| SRA-220 | 220 | 10.7 | 1,200 | 544 | 2,281 | 207 | 109 |

| SRA-80-V* | 80 | 4.1 | - | 144 | 177 | - | - |

*Reinforcement section suitable for SRA-140, SRA-180 and SRA-220

High Load Capacity for Sections

The load diagram can be used for reference when selecting the section size while taking a specific maximum load and the suspension distances into account. The suspension distances stated are based on a deflection of 1:300, the common value for calculating crane systems. Smaller deflection values such as 1:400 may be required for certain applications.

Example: With a maximum load of 200 kg and a predetermined suspension distance of 5,000 mm the profile SRA-140 is used. The maximum deflection is then 17 mm (5,000 mm / 300).

Transport Trolley

| Type | Height [mm] | Length [mm] | Width [mm] | Weight [kg] | Max. lift capacity [kg] tension |

Max. lift capacity [kg] pressure |

|---|---|---|---|---|---|---|

| Transport trolley TRO-R-SRA-GAB-1000 |

125 | 240 | 55 | 1.4 | 1,000 | 1,000 |

| Double transport trolley TRO-R-SRA-GAB-1200* |

150 | 500 | 75 | 6.5 | 1,200 | 1,200 |

*Subject to technical changes without notice

Videos

Discover application examples of the product in various industries - user-friendly, informative and practical.

No suitable videos found? Then take a look at our media center.

.jpg)

.jpg)

.jpg)