Vacuum Suction Cups

- Our product range includes a variety of suction cups with various shapes, sizes and materials, providing the right suction cup for every application. Suction cups consist of a elastomer part and a connection nipple.

Vacuum suction cups play a major role in a vacuum system. They form the interface to the workpiece, which is why they have to meet a number of requirements. The requirements result from the workpiece properties as well as the application. For example, resistance to high temperatures, oils or UV light may be required. Use in the food industry demands different properties. The application itself can also require, for example, the absorption of high lateral forces, a long service life or the compensation of height differences.

A suction cup is the elastomer part of a vacuum gripper. It can be screwed to the gripper in a vacuum system using a suitable connection element.

Due to the variety of requirements that a suction cup has to meet, a wide selection of materials is crucial. The properties of the materials ensure the required chemical, mechanical and temperature resistance of the vacuum suction cup. Our material experts in the elastomer team understand the challenges and are able to develop the right material for the most diverse requirements. Learn more about the materials used for suction cups here.

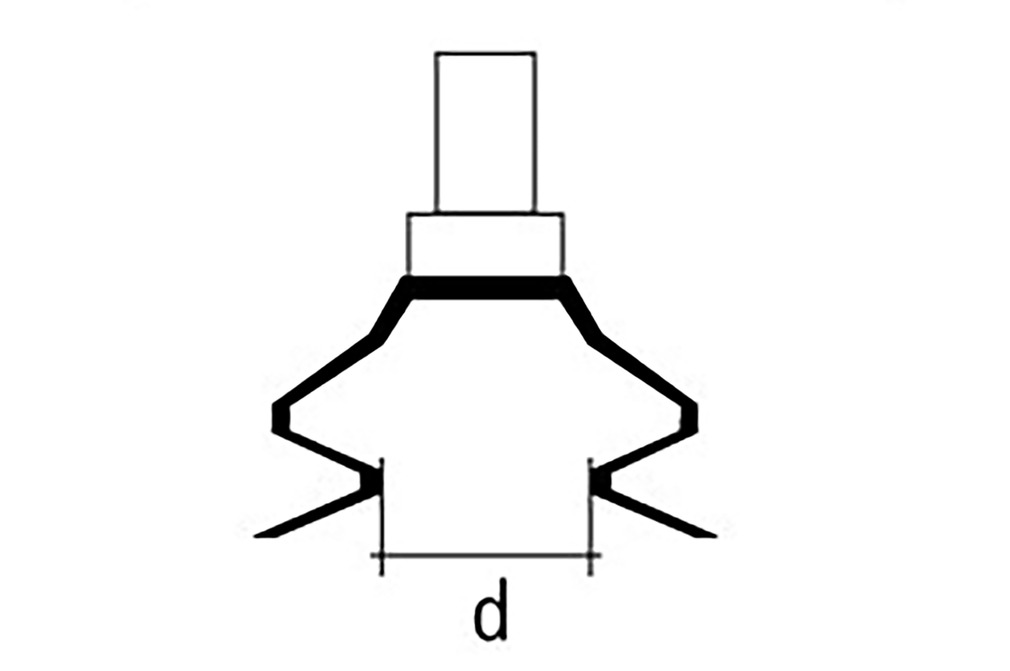

Vacuum grippers are available in round and oval designs. Round suction cups are suitable for handling flat workpieces. Oval vacuum suction cups are used for narrow, elongated workpieces. A distinction is also made between flat suction cups and bellows suction cups.

Flat suction cups benefit from low overall height and low internal volume. The low volume ensures short blow-off times. In addition, the flat suction cup design has good intrinsic stability and ensures high positioning accuracy. Flat suction cups are primarily used in highly dynamic processes.

Suction cups with one or more bellows have the advantage that they can compensate for height differences and that they are more flexible than flat vacuum suction cups. The bellows also provide a damping effect when the gripping system is placed on the workpiece. This allows sensitive workpieces to be gripped gently using a bellows suction cup. Bellows suction cups are usually used for film-packed workpieces as well as for car body parts or electronic components.

A suction cup is connected to the vacuum system using a connection element. Together, vacuum suction cups and connection elements form a vacuum gripper. Depending on the requirements, the connection element is vulcanized, inserted, tightly clipped or screwed on. A suction cup can be delivered fully assembled or self-contained (vacuum suction cup and connection element).

Schmalz suction pads are available for universal and special applications. Learn about the advantages of the flat suction pads or bellows suction pads.

Application and environmental conditions are decisive for the selection of the appropriate suction pad and material.

The elastomer part of the suction pad requires special storage and cleaning. Observe the instructions on how to ensure the service life of your Schmalz suction pad.

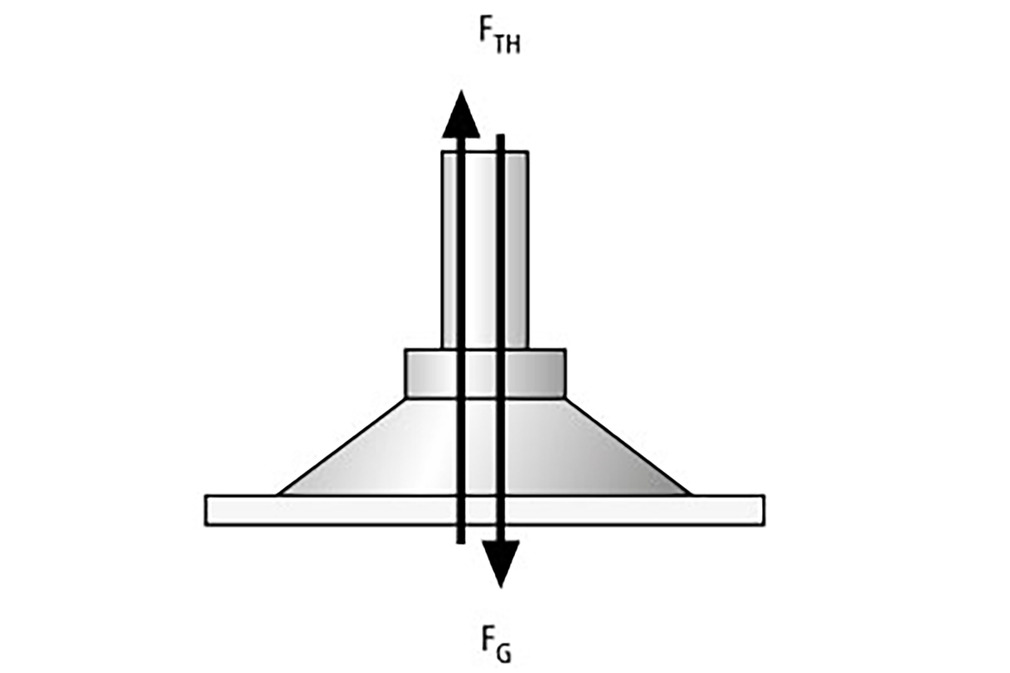

Technical data are necessary to optimally design the vacuum system. Schmalz provides information on suction force, transverse force, internal volume, suction stroke and camber radius.

The design of the suction pad always depends on the specific application. Therefore, calculations and determinations of physical values are necessary in advance for the correct design.

Our selection guide for vacuum cups helps you to find the right cup for your applications based on characteristics such as cup material, size or workpiece.

Experience the Schmalz grippers in action in our media centre. Our experienced Schmalz system consultants will be happy to help you with the design of your vacuum system.