Vacuum Technology for the Wind Energy Industry

For the past few years, the wind energy sector has been one of the fastest growing industries in the world. The energy transition from fossil fuels to renewable energies has spurred on its development. Recent technological advancements have led to constant increases in the efficiency of wind turbines. The trend towards higher and higher hubs and increasingly large rotor blades is continuing. Handling components that are up to 85 meters long and weigh several tons, as well as producing the correct blade shape with a high level of precision, pose new challenges to manufacturing. In its effort to keep up with this rapid growth, the rotor blade production sector is now moving towards automated mass production, meaning that innovative concepts and vacuum handling solutions will be necessary for future processes.

Schmalz develops customer-specific vacuum lifting devices for various production technologies and forms. This allows customers to reduce their process times to a minimum, increase quality considerably and improve ergonomics. Schmalz solutions are used primarily in the production of rotor blades and nacelles, but are also used to produce control cabinets and other elements involved in wind energy. A reliable visual and audible warning device ensures maximum safety during handling.

Schmalz offers you the suitable solution in the wind energy industry

Click on the individual areas to learn more.

Vacuum Technology for Rotor Blade Production

Requirements for Vacuum Technology

Demolding in observance of the demolding forces

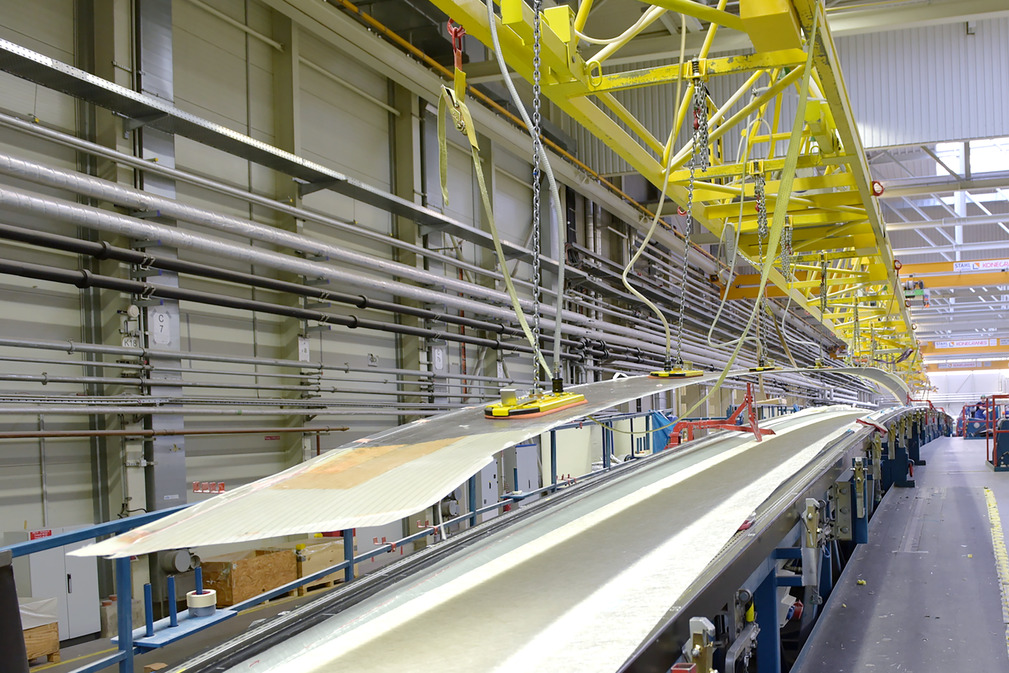

Vacuum lifting devices VacuMaster for rotor blade production simplify various demolding and transport processes considerably. The lifting devices are equipped with multiple suction cups that grip the workpiece gently and securely.

Safety during handling of workpieces weighing several tons

The vacuum lifting device VacuMaster has one or two vacuum circuits, a large vacuum reservoir and an additional mechanical safeguard such as cloth retaining straps or mechanical safety clamps. This way, the lifting device ensures maximum process reliability, even when transporting rotor blades and their components. The lifting devices are also equipped with a visual and audible warning device.

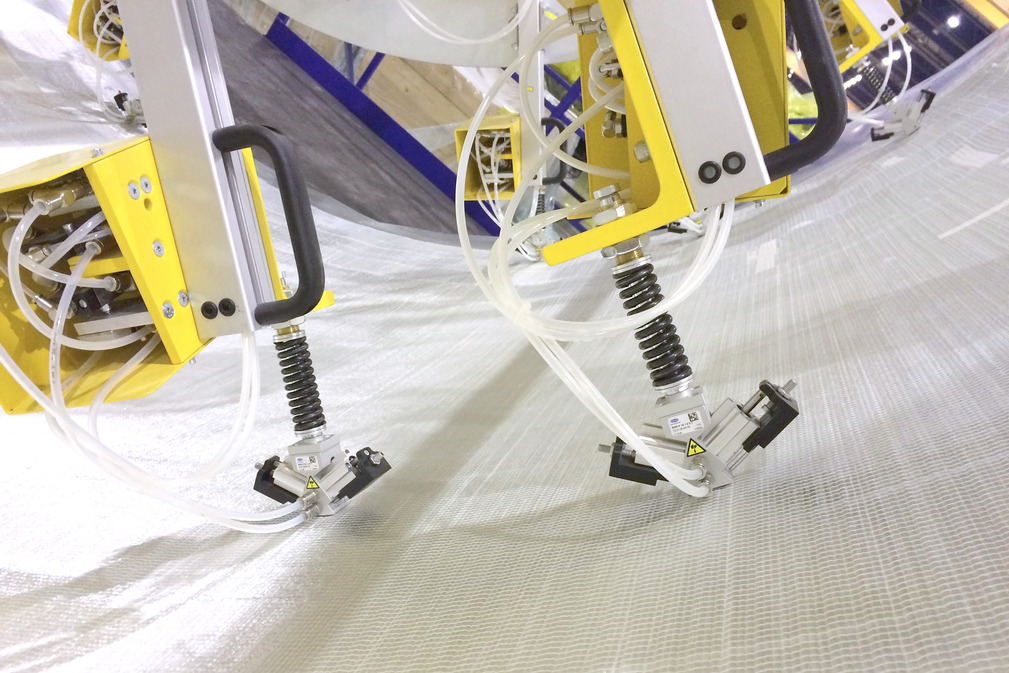

Flexible adaptation to different shapes

The lifting device’s suction cups have a special sealing profile that optimally adapts to the workpiece surfaces. All suction cups can be switched on and off using manual slide valves. The suction cups are attached to a chain suspension, a rigid suspension with a linear trolley or linear drives for automatic height adjustment. This means that the lifting devices can both adapt to the shapes of lifted workpieces, and lift shapeless workpieces.

Product recommendations for the Rotor Blade Production Sector

Vacuum Technology for Nacelle Production

Requirements for Vacuum Technology

Rotating and swiveling the cladding

Individual components are swiveled or rotated to bring them into their final positions during the final assembly of nacelles. Side panels are swiveled up to 90°, while some roofing elements are rotated 180°. Vacuum lifting devices from Schmalz can be equipped with an electrical swiveling unit to position the components safely and gently.

Safe handling of workpieces weighing several tons

The vacuum lifting device VacuMaster has one or two vacuum circuits, a large vacuum reservoir and an additional mechanical safeguard such as cloth retaining straps or mechanical safety clamps. With these features, the lifting device ensures maximum process reliability during nacelle production.

Flexible vacuum modules that can be switched off individually

The suction cups of the vacuum lifting device flexibly adapt to different component shapes and surfaces using suspension that is spring-mounted or mounted on gimbals. Schmalz’ extensive product range offers the right suction cup for every surface. The suction cups can easily be switched on and off using the manual slide valves, allowing the vacuum lifting device VacuMaster to be adapted to different components.

Product recommendations for the Nacelle Production Sector

Documents

Videos

Discover application examples of the product in various industries - user-friendly, informative and practical.

No suitable videos found? Then take a look at our media center.