Thin Glass Grippers STGG

- Suction area: 100 x 55 mm and 170 x 105 mm

- Material suction area: PEEK

- Suction rate: 31 to 235 l/min

The rapidly growing share of electric vehicles is leading to a very high demand for lithium-ion batteries. In order to meet the demand for long ranges, the quality and performance requirements for batteries and their production processes are also constantly increasing. Vacuum components from Schmalz meet the high demands of the industry and are used in automated cell production and module assembly. In addition to automation technology, Schmalz also offers vacuum lifters and crane systems for the ergonomic and safe handling of heavy battery modules.

Highly dynamic Pick & Place

Gentle gripping

Contamination-free handling

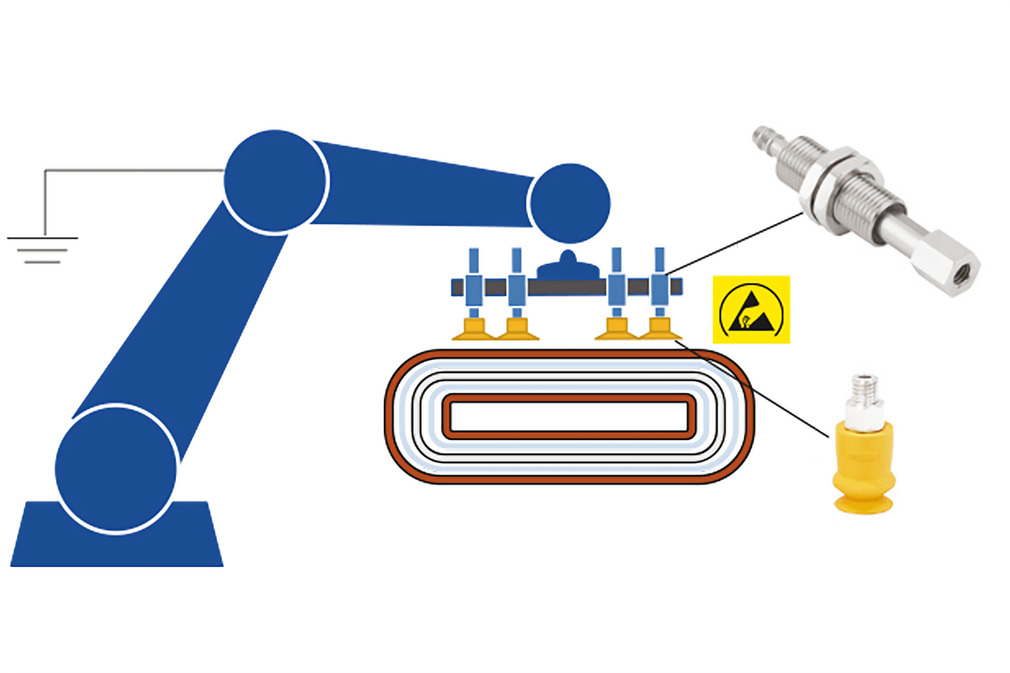

Safe electrostatic discharge

Format flexible gripper solutions

Deformation-free gripping

Electrolyte-resistant suction cups

Safe and intelligent solutions

Configurable grippers

Integrated vacuum generation

Secure gripping

Gripping directly on the battery terminals

Secure gripping

Flexible configuration

Precise handling

Ergonomic and safe handling

Product properties and process optimization in the battery industry

More information on deformation, contamination, electrolyte resistance, cleanroom suitability and cleanroom classification and standardization.

Quick to integrate, fully networked, constantly monitored. Our Industry 4.0 range for the digital factory.

Static charges and discharges cause various problems such as damage to the electrode material, adhesion of the separator foils to the gripper and adhesion of foreign particles as well.