Machine Vision (industrial image processing)

Machine vision (industrial image processing) involves the use of automated systems to interpret and analyze visual data in manufacturing and production settings. The term is often described as "machines with eyes", as cameras, lighting systems and software work together to capture and analyze visual data and derive automated decisions on this basis.

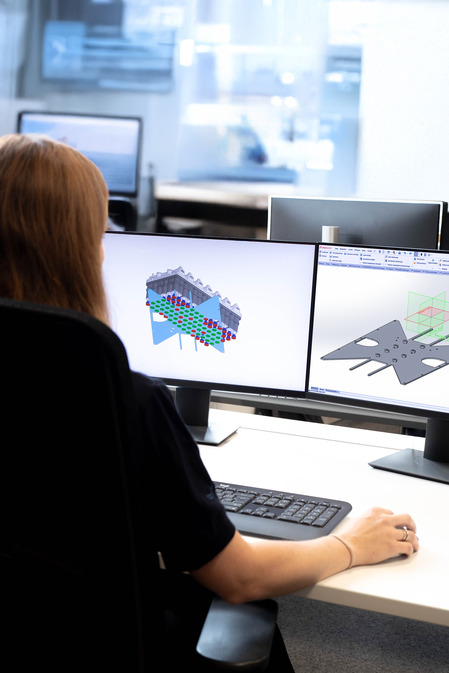

Operation mode of Machine Vision

A machine vision system consists of cameras, lighting, image processing, software algorithms and a control unit that translates the captured information into specific actions. Typical applications include the precise positioning of components, the automated sorting of products and bin picking - the targeted removal of individual parts from chaotically filled containers.

While classic image processing systems are rule-based, modern machine vision solutions are increasingly using deep learning (DL) and artificial neural networks to reliably handle complex or varying requirements. This enables machines to replicate cognitive capabilities that are comparable to human perception, but are significantly faster and more robust.

Areas of application and advantages

Machine vision is a key driver of industrial automation. In quality assurance, the technology precisely detects defective products and thus reduces rejects, which improves product quality. In logistics, it is used to read barcodes and QR codes and transparently track products along the supply chain. In addition, machine vision systems increase productivity as they are constantly reliable and significantly speed up manufacturing processes.

One particularly important field of application is optical investigation. Conventional industrial image processing systems often reach their limits when it comes to distinguishing between image fluctuations caused by the environment and qualitative deviations. AI- and deep learning-based machine vision models can reliably identify such differences and automatically classify inspection items, e.g., into "OK" (acceptable) and "NOK" (not acceptable). Machine vision thus enables robust solutions for complex inspection tasks that would be difficult or impossible to implement with conventional image processing.

Machine vision vs. computer vision

Unlike general computer vision, which includes applications in areas such as medical image analysis, autonomous driving or video surveillance, machine vision is specially oriented towards industrial image processing systems. The focus is on reliability, repeatability and stability in manufacturing. Machine vision combines proven hardware with modern software, AI and neural networks to precisely process image data even under demanding production conditions and derive automated decisions.

Benefits of machine vision in the industry

Machine vision offers considerable advantages for companies. It enables more precise and faster quality assurance, reduces error costs, increases efficiency and can be seamlessly integrated into Industry 4.0 processes. Through the use of AI and machine learning, machine vision is becoming a key technology for industrial automation and a strategic tool for ensuring long-term competitiveness and product quality.

Related terms

Digital Engineering

Schneller, flexibler. nachhaltiger: Erleben Sie, wie klassische Ingenieurskunst und modernste digitale Technologien zusammenkommen – von der virtuellen Planung bis zum digitalen Zwilling.