Condition monitoring

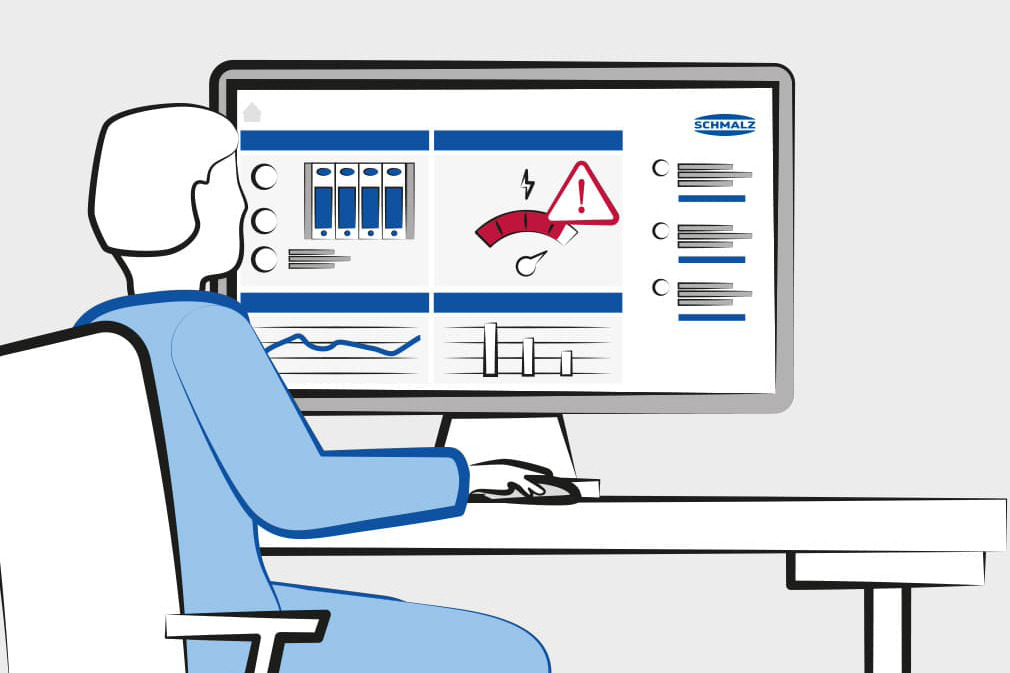

Condition monitoring refers to the continuous or periodic recording and analysis of the technical condition of machines, systems or processes. The aim of this maintenance strategy is to detect deviations from the normal condition at an early stage, avoid unplanned downtimes and extend the service life of machines.

Typical physical parameters that are monitored in a condition monitoring system (CMS) are vibrations, temperatures, pressures, oil and lubricant quality and audible signals.

Operation mode of condition monitoring

The basis of condition monitoring is condition detection using sensors, such as vibration sensors, pressure and temperature sensors or particle monitoring systems for hydraulic fluids.

The measurement data is transmitted via a network, wirelessly or wired, to a central monitoring system, where it is documented, compared with reference or limit values and analyzed using automatic measurement data processing. In the diagnostic phase, anomalies and damage patterns are detected so that necessary maintenance measures can be planned in good time.

Areas of application

Condition monitoring is primarily used in Industry 4.0 and in smart factory environments. Typical applications include machine monitoring in power plants, turbine or generator monitoring, the monitoring of rotating systems such as pumps, compressors, electric motors or machine tools as well as process monitoring in process technology. Condition monitoring also plays a central role in highly sensitive areas such as rolling mills, aviation or rail transport.

Condition monitoring in the context of predictive maintenance and Industry 4.0

The recorded condition data therefore serves as the basis for predictive maintenance (condition-based maintenance). Using methods such as signal analysis, pattern recognition or acoustic emission analysis, even complex machine damage can be safely predicted. Modern solutions use machine learning, big data condition monitoring and the Industrial Internet of Things (IIoT) to evaluate even large amounts of data in real time.

Related terms

Digital Engineering

Faster, more flexible, more sustainable: experience how the classic art of engineering and state-of-the-art digital technologies come together - from virtual planning to the digital twin.

Digitalization

Seamlessly digital: Schmalz supports you with smart solutions along the entire life cycle.