Requirements for Vacuum Technology

High output quantities

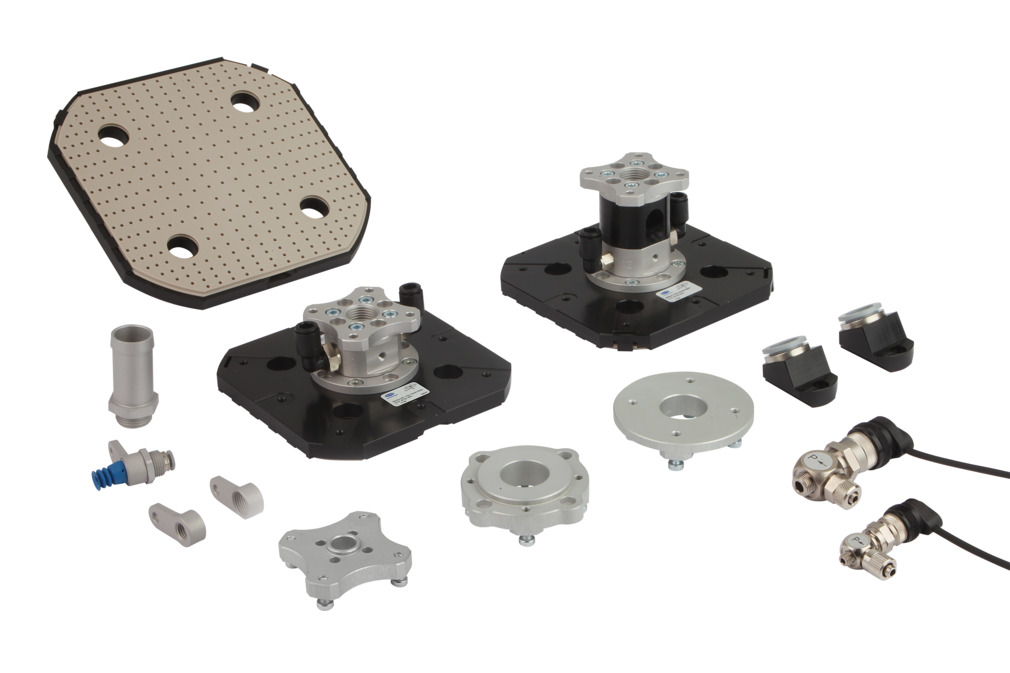

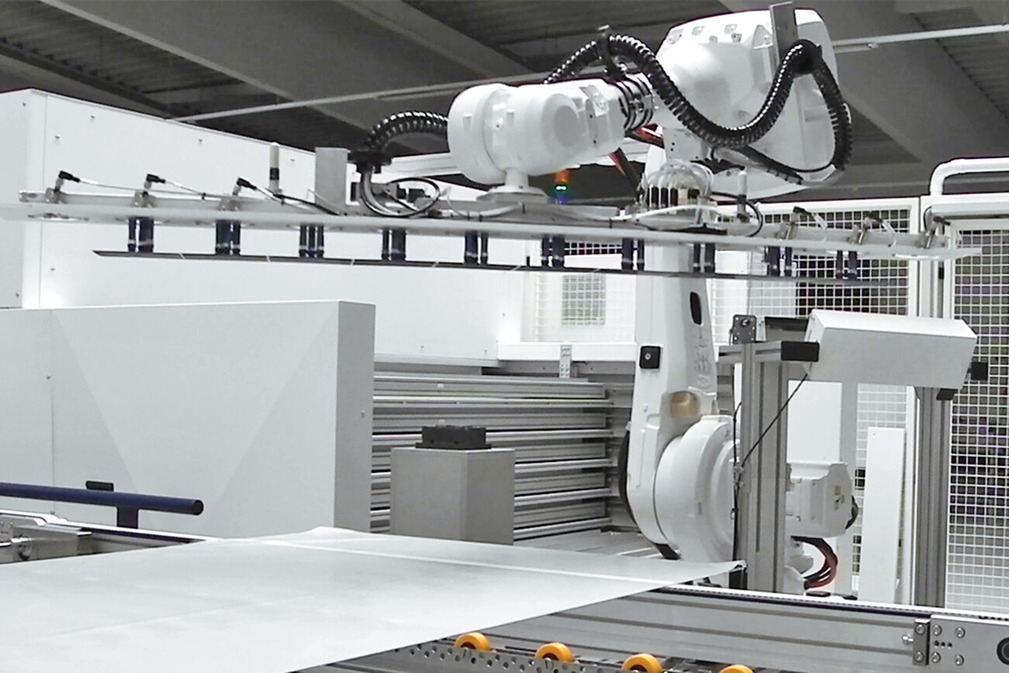

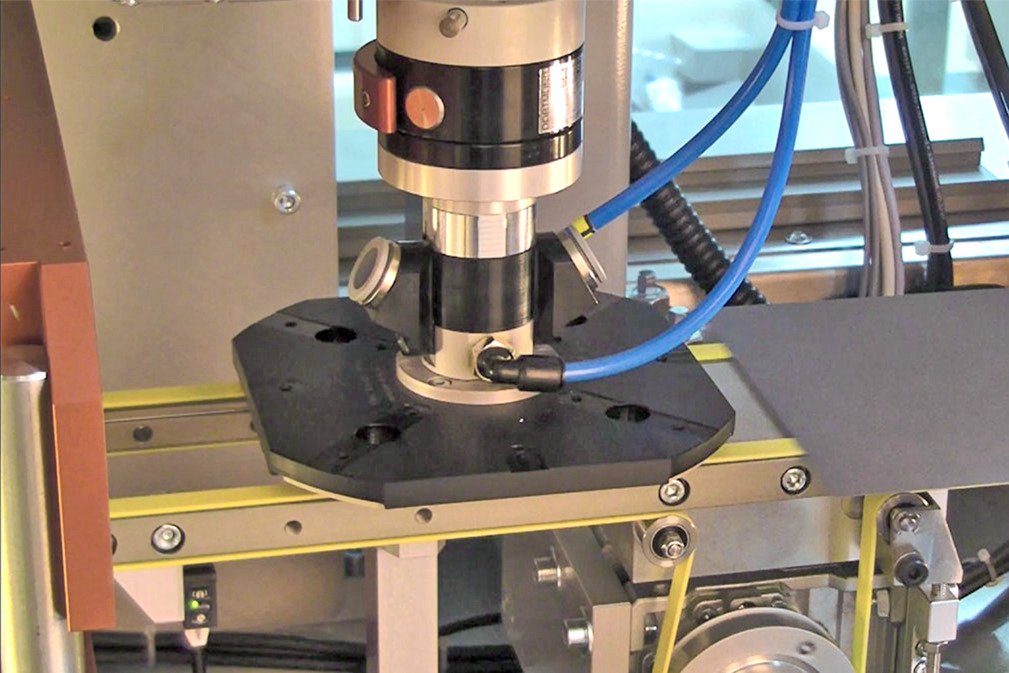

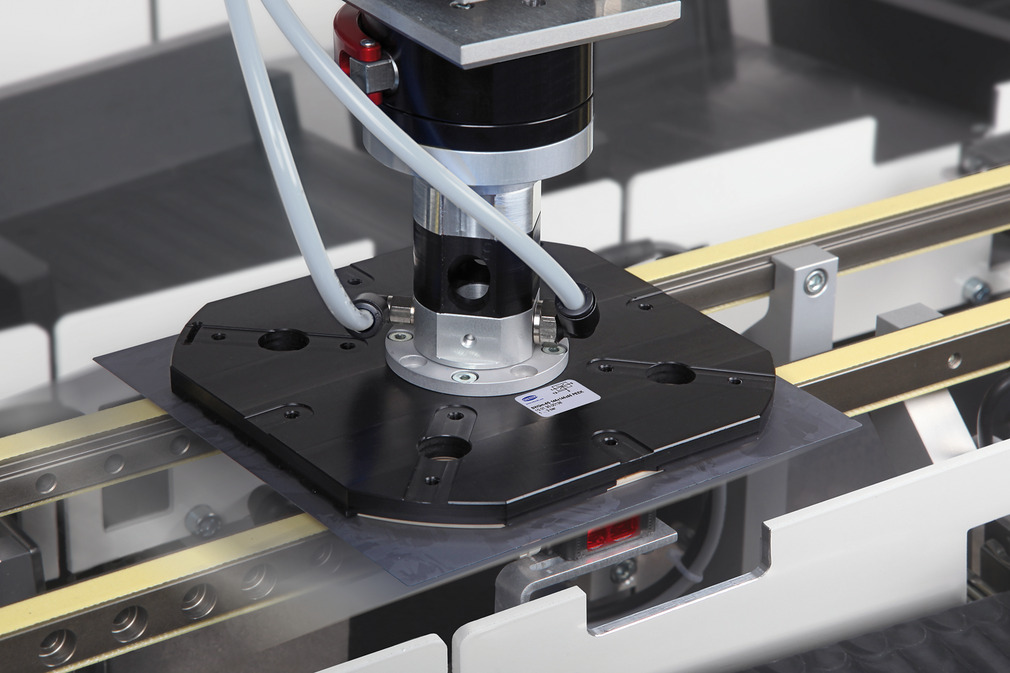

Cell manufacturing also requires handling cycle times of less than one second. Because of the high acceleration rates, the grippers must apply high holding and shear forces. What’s more, the wafer gripper SWGm can integrate inspection and testing tasks during handling by using the optional integrated sensors.

Low breakage rates

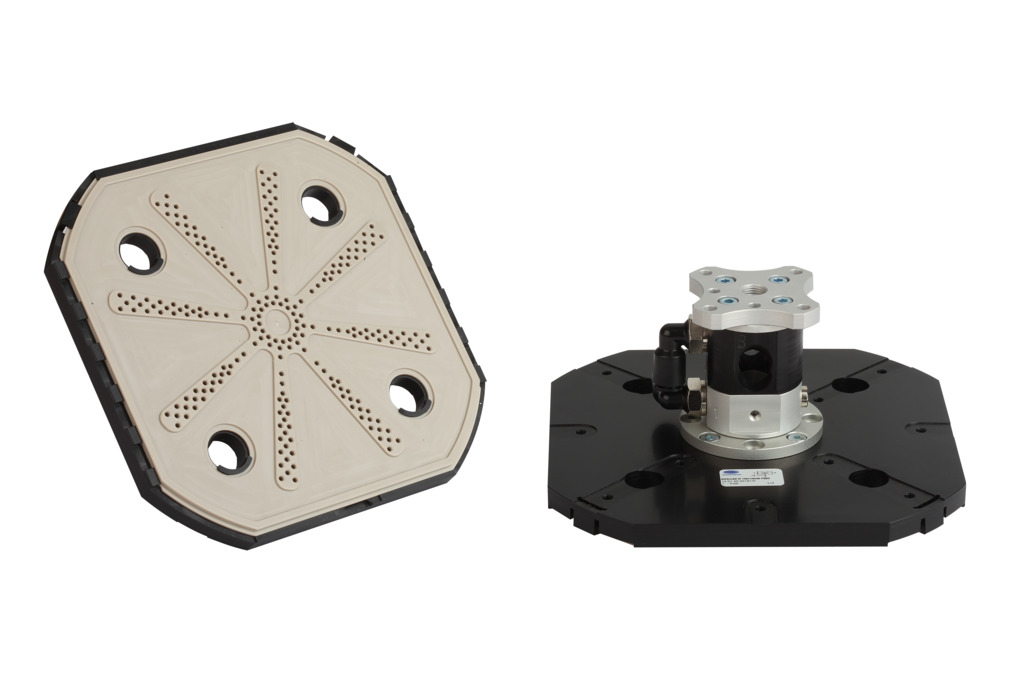

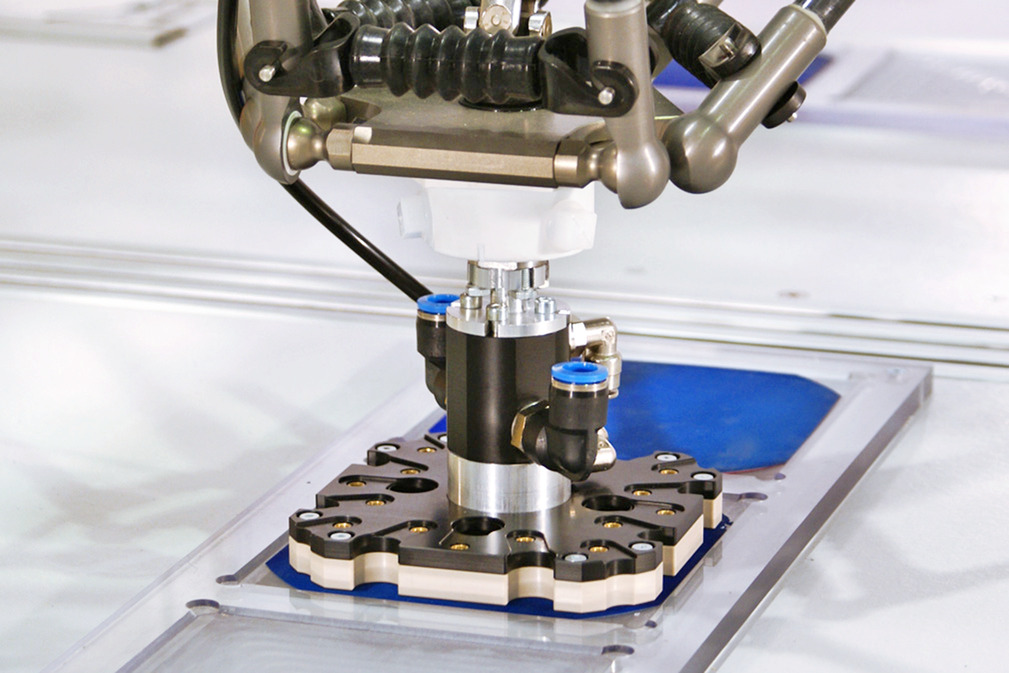

The breakage rate of the processsignificantly affects the output quantities. For that reason, there is a high focus on handling the cells as gently as possible. The special gripper SWGm enables minimum breakage rates compared to other handling technologies. The large contact surface and low vacuum level mean that the gripper generates only minimum surface pressure, making it particularly gentle.

Contamination-free handling

Contamination of the cell surfaces must be avoided throughout many processes in the production chain. Because marks or contaminations have a negative effect on the chemical processes, particularly before the plasma coating process. The wafer gripper SWGm with a contact surface made of contamination-free PEEK material is the optimal solution. Suction cups made of the markless material HT1, can also be used in cell manufacturing.

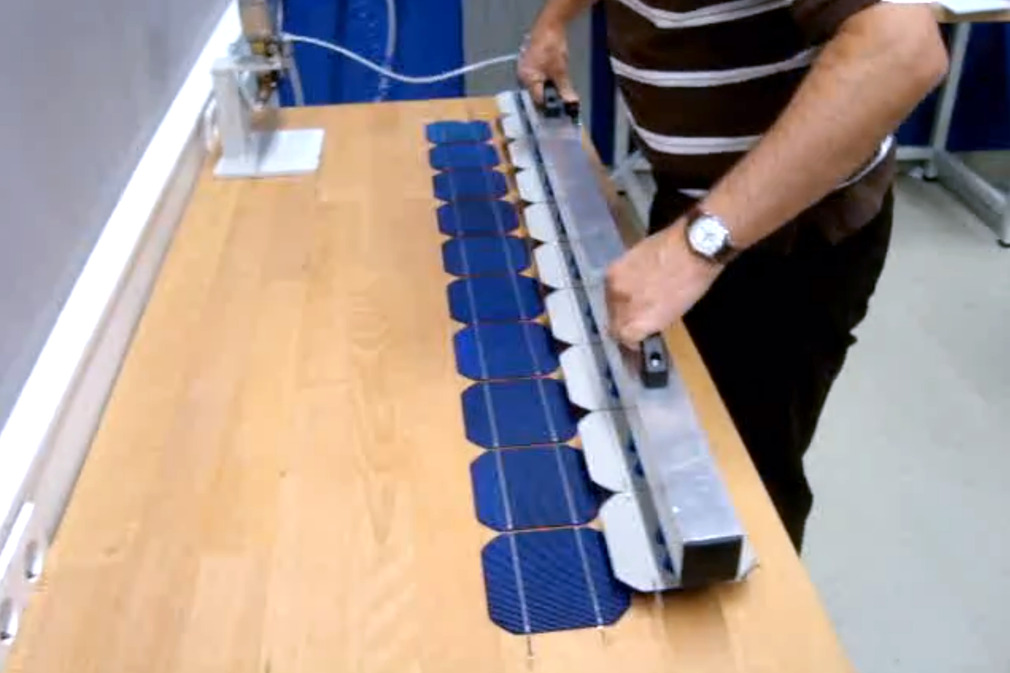

Separating the cells

Separating the cells places high demands on the gripping technology. The floating suction cup SBS generates a high flow rate, which is used to achieve a larger engamenet distance to separate the cells. The optional floating suction cup modules SBSm, which can be integrated into the wafer gripper SWGm, allow the advantages of the wafer gripper to be combined with the engagement distance of floating suction cups. Sensors on the wafer gripper SWGm not only allow coverage monitoring, distance measurements and breakage detection, but also detect when two cells have been picked up. Detecting double layers during destacking processes reduces cycle times considerably.

.jpg)