Vacuum Clamping Technology for Wood

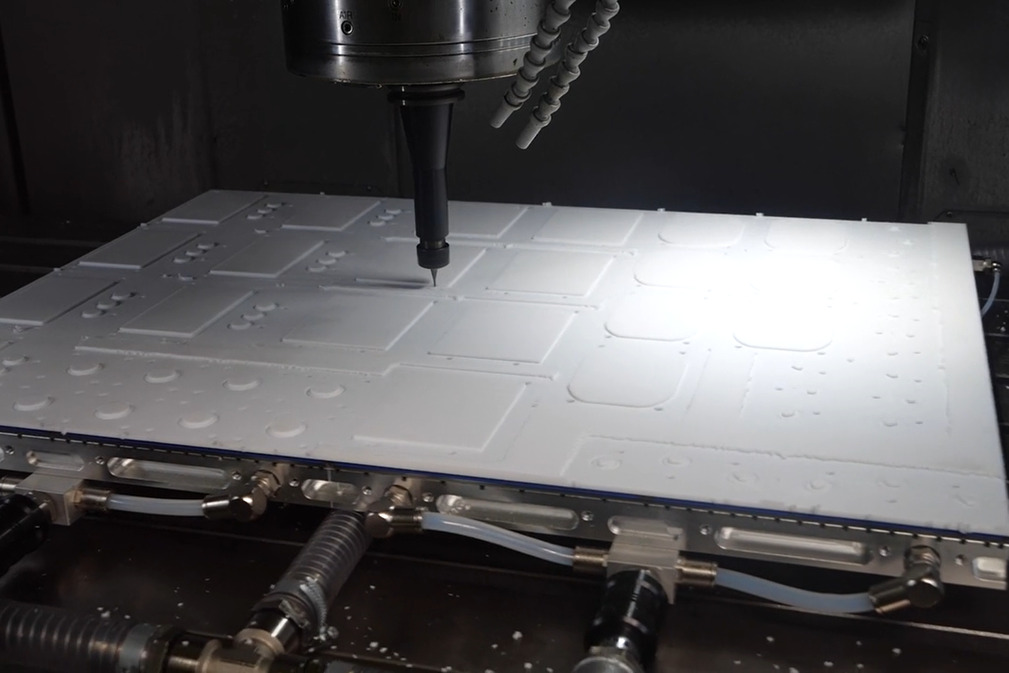

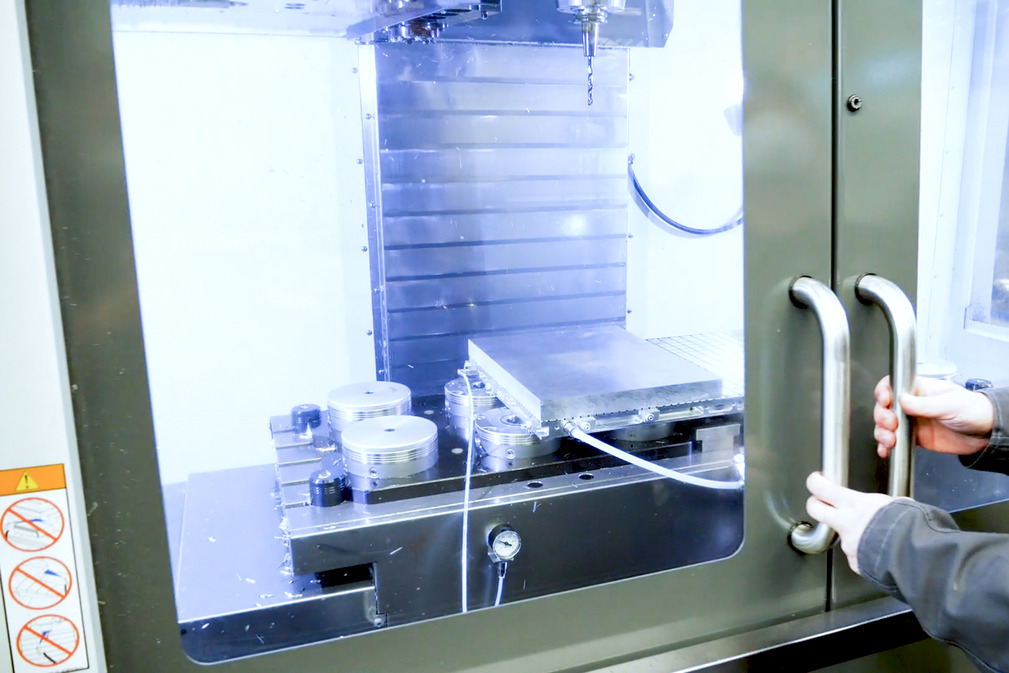

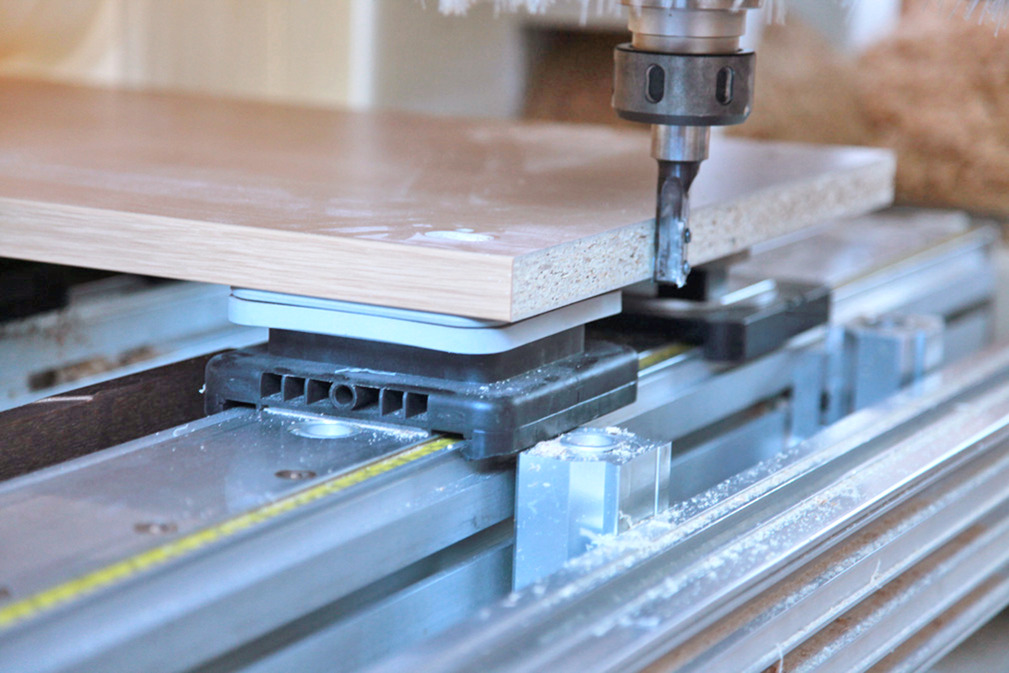

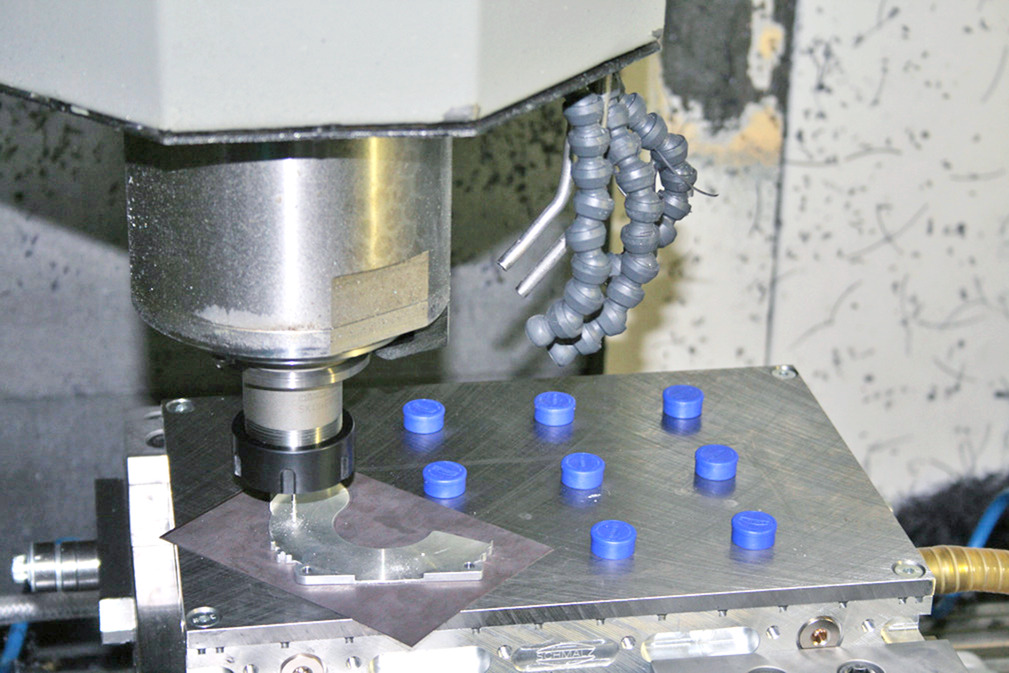

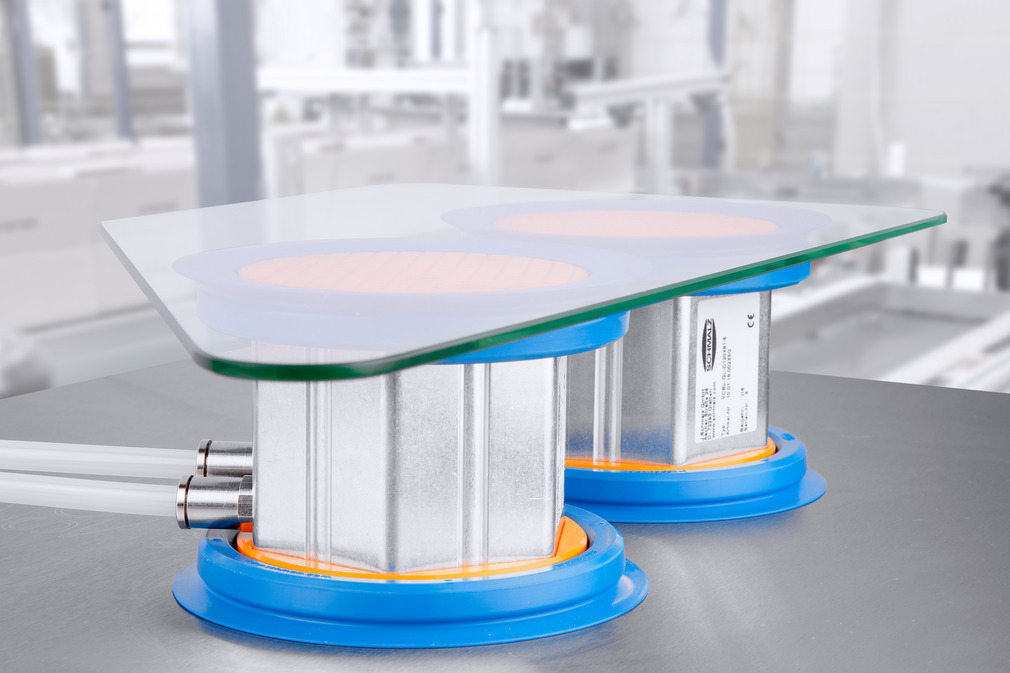

- Vacuum clamping technology for CNC machining of wooden workpieces

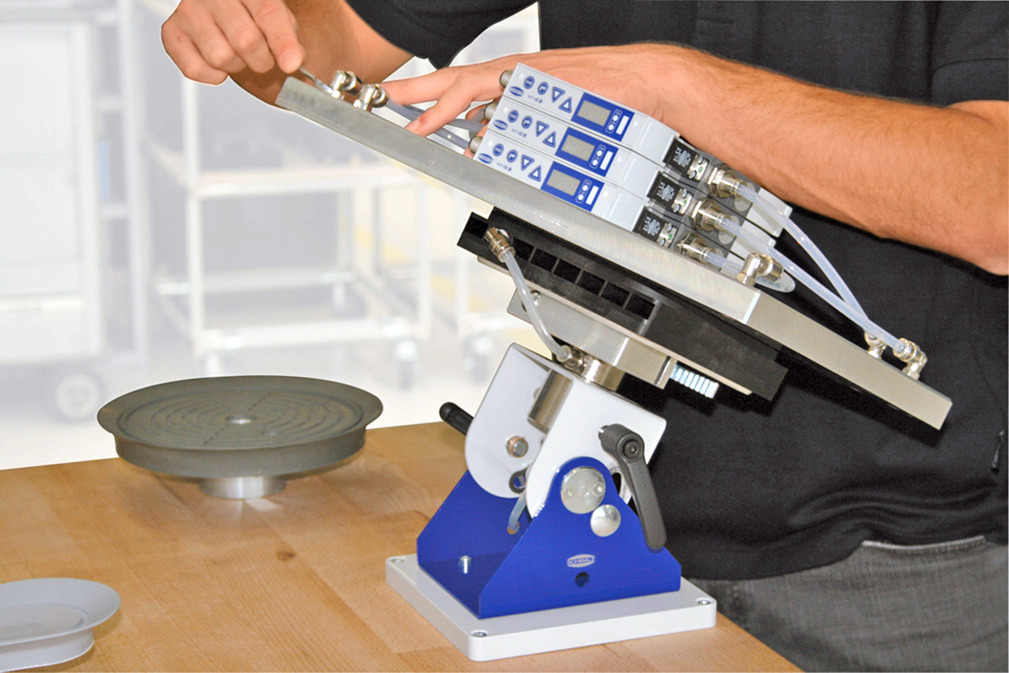

- Solutions for console table, grid table and flat table systems

- Clamping equipment for both narrow workpieces and workpieces made from solid wood

- Clamping solutions for modernizing CNC machining centers