Vacuum Ejectors

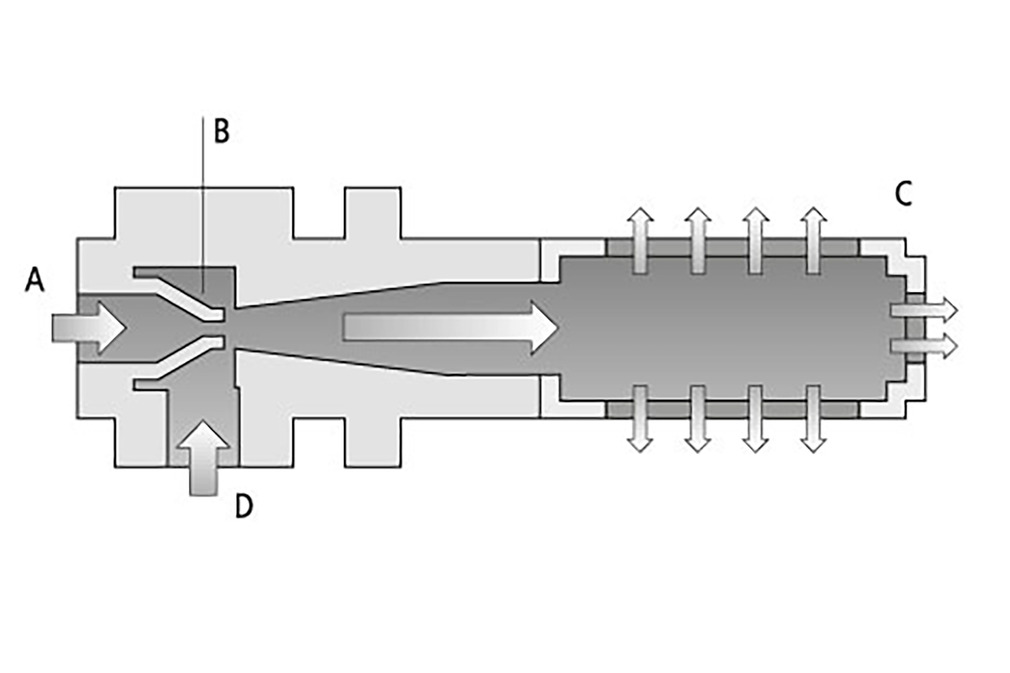

Ejectors work on the Venturi principle; they are divided into singlestage ejectors and ejectors featuring eco-nozzle technology. The compressed air is supplied through connection (A) to ejectors. It flows through the venturi nozzle (B). The air is accelerated and compressed during this process. After passing through the nozzle, the accelerated air slows down once again and a vacuum is created. Air is drawn in this way through the vacuum connection (D). The aspirated air and the compressed air escape through the silencer (C).

With ejectors featuring eco-nozzle technology, the vacuum passes through several venturi nozzles arranged in a row. The volumes of the individual nozzles add up to form a total suction rate.

Advantages of ejectors

- Compact shape

- Low weight

- Fast vacuum generation

- No flexible parts, resulting in low maintenance and low wear

- Choose an installation position

- No heat generation

Typical areas of application

- Industrial robot applications in all industries, such as feeder applications in the automotive industry

We distinguish between three types of ejectors:

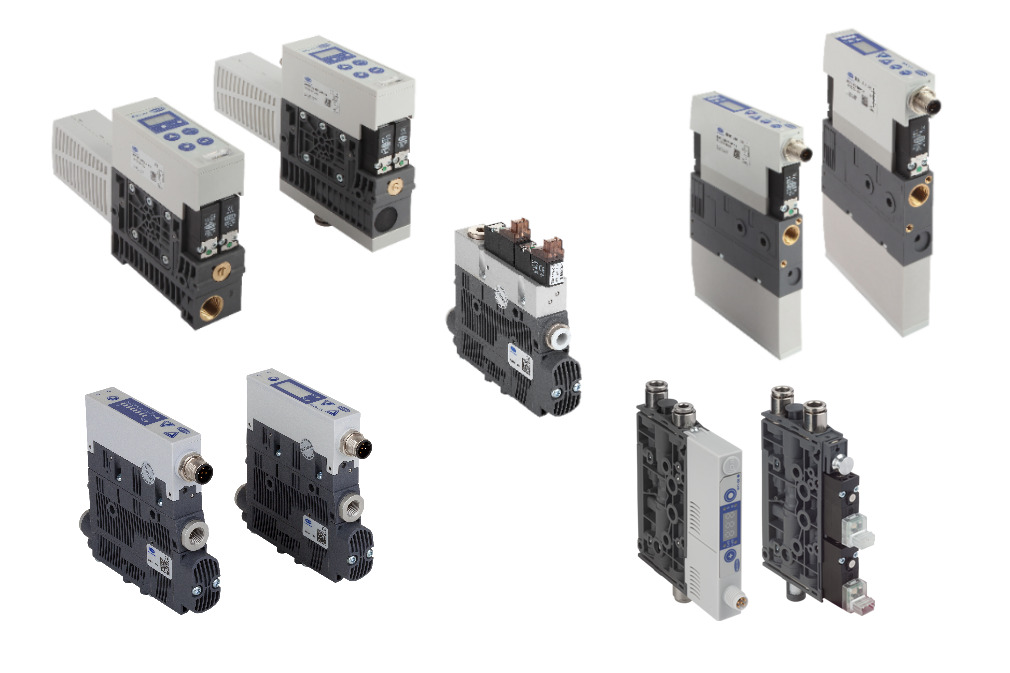

Ejector modules

- Ejector modules featuring eco-nozzle technology for efficient vacuum generation and high suction rate with minimal air consumption

- For use in the packaging industry, e.g. in carton erectors for direct installation without separate housing

Basic ejectors

- Vacuum generators without valve control and system monitoring with high maximum vacuum level

- Used mainly to handle air-tight workpieces

Compact ejectors

- Vacuum generator with integrated valve technology; system monitoring and IO-Link technology are available as selected variants

- Control of pick-up and blow-off feasible without external valves

- Optional with integrated air-saving regulation

- Used in fully automatic handling systems (e.g. sheet metal processing, automotive industry, robot applications)

Compact ejector with air-saving regulation

Compact ejectors have an integrated air-saving regulation. This function interrupts vacuum generation as soon as a safe vacuum value has been reached. Vacuum generation is switched back on only once the value falls below the preset minimum vacuum value. Compact ejectors with an air-saving regulation use far less compressed air than a conventional vacuum ejector.