Product properties and process optimization in the battery industry

Deformation

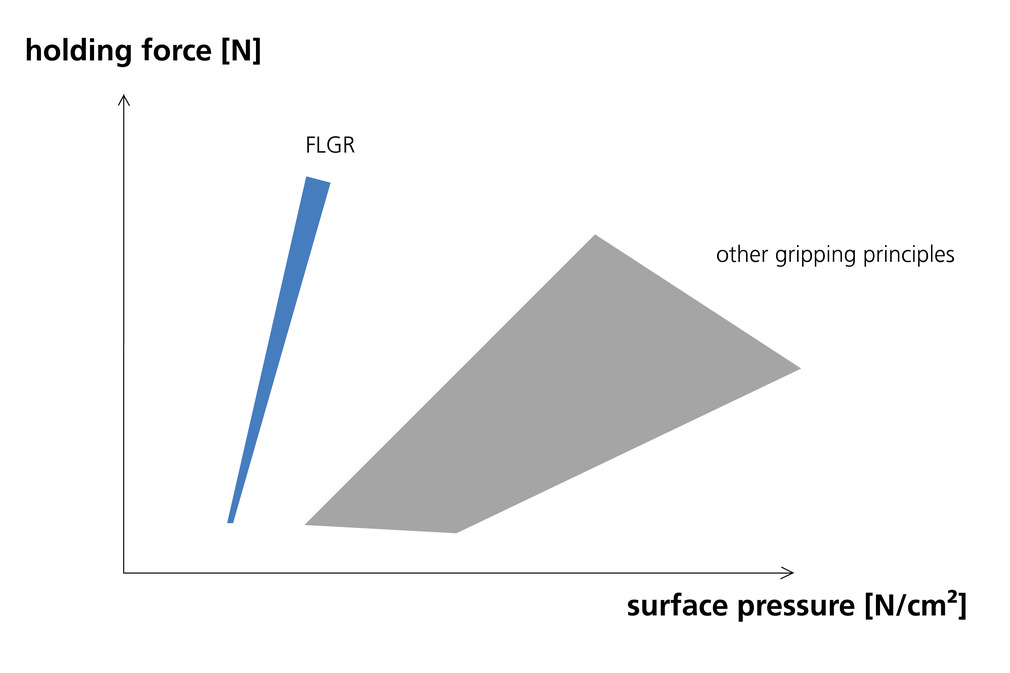

Gentle handling of the electrodes and separators by reducing the dynamic and static forces on them by means of optimum dimensioning and distribution of the suction points. Proven lower surface pressure compared to other gripping principles such as elastomer suction cups or Bernoulli grippers.

Image 2: When using suction cups

Image 3: When using FLGR

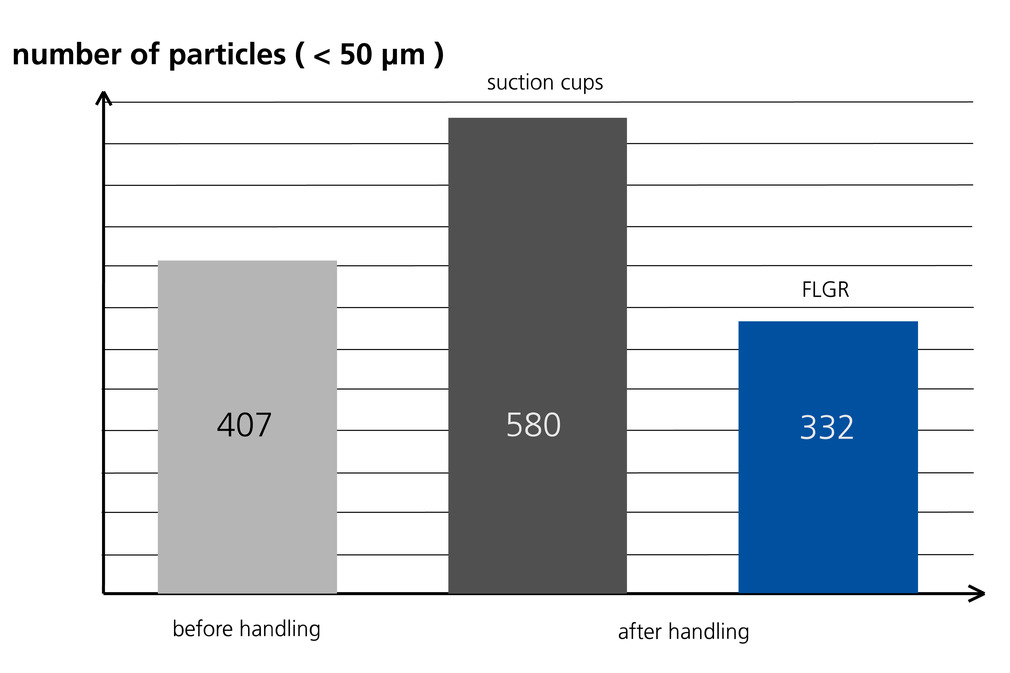

Contamination

Suction surface made of special material PEEK (polyetherether ketone) minimizes mechanical abrasion and prevents chemical contamination. The high volume flow of gripper also removes particles from the electrode, which are then removed from the working area by exhausting the exhaust air.

Image 2: When using suction cups

Image 3: When using FLGR

Electrolyte Resistance

An important component in every battery is the electrolyte, which ensures the transport of ions between the electrodes. The complex system of solvent, conductive salt and additives can attack components that come into contact with it. Schmalz offers suction cups made of materials resistant to corrosion by electrolytes. Compared with suction cups made of other materials, it can be used for a long time, to improve the productivity and output of the line.

Cleanroom Suitability

Products of Schmalz can be used in mostly every cleanroom class. Together with high level institutes the products of Schmalz have been tested and certified. This certification is based on different regulations and official standards.

| Cleanroom Classes | Schmalz Products* | ||||

|---|---|---|---|---|---|

| ISO 14644-1 | Vacuum Suction Cups | Special Grippers | Gripping Systems | Mounting Elements | Vacuum Generators |

| ISO 1 | PFYN, FSG, SGON | SCG, FLGR (STGG)** | FSTIm | ||

| ISO 2 | FSGA | FM-SW | FSTIm (with rotation lock) | ||

| ISO 3 | SGPN, SPF-ED | ||||

| ISO 4 | FSGA-SI | SCPS/SCPSi, SCPSb | |||

| ISO 5 | |||||

| ISO 6 | |||||

| ISO 7-9 | All products of Schmalz are compliant with cleanroom class ISO 7-9 | ||||

*Vacuum components exemplarily tested by following the standard VDI-2083

**The FLGR series is a customized product and has received certification based on standardized STGG.

Cleanroom Classification and Standardization

| ISO 14644-1, JIS B 9920 | FED-STD-209D equivalent | |||||||

|---|---|---|---|---|---|---|---|---|

| Maximum particles /m³ | Maximum particles /ft³ | |||||||

| 0.1 µm | 0.2 µm | 0.3 µm | 0.5 µm | 1.0 µm | 5.0 µm | 0.5 µm | ||

| ISO 1 | 10 | 2 | - | - | - | - | - | |

| ISO2 | 100 | 24 | 10 | 4 | - | - | - | |

| ISO 3 | 1,000 | 237 | 102 | 35 | 8 | - | 1 | |

| ISO 4 | 10,000 | 2,370 | 1,020 | 352 | 83 | - | 10 | |

| ISO 5 | 100,000 | 23,700 | 10,200 | 3,520 | 832 | 29 | 100 | |

| ISO 6 | 1,000,000 | 237,000 | 102,000 | 35,200 | 8,320 | 293 | 1,000 | |

| ISO 7 | - | - | - | 352,000 | 83,200 | 2,930 | 10,000 | |

| ISO 8 | - | - | - | 3,520,000 | 832,000 | 29,300 | 100,000 | |

| ISO 9 | - | - | - | 35,200,000 | 8,320,000 | 293,000 | 1,000,000 | |