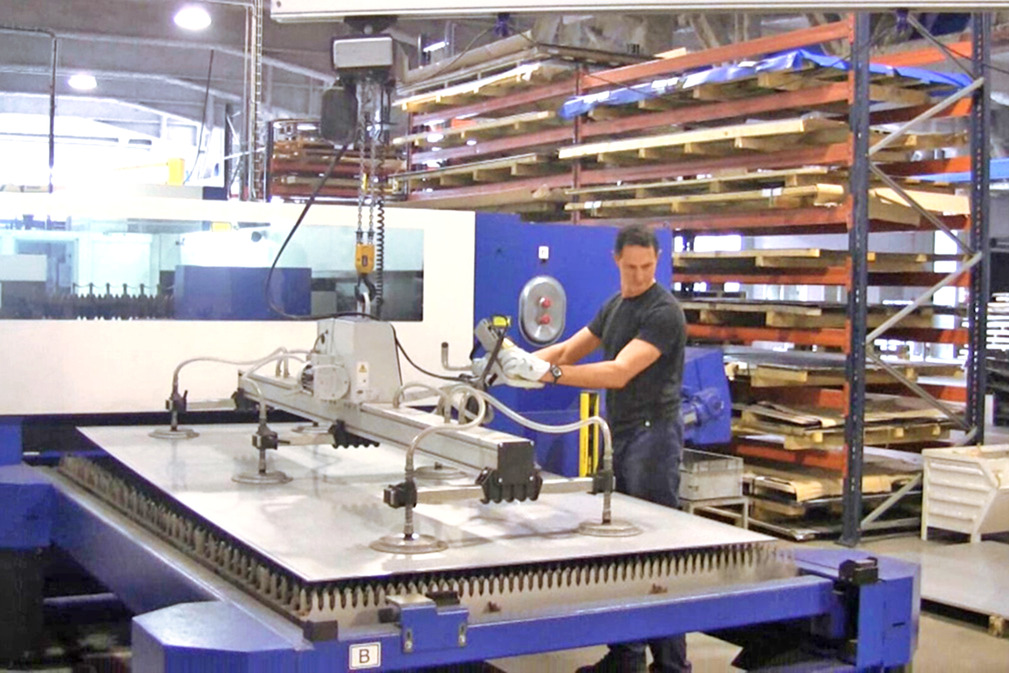

Vacuum Tube Lifters JumboErgo

- Tube lifter JumboErgo for dynamic handling of flat workpieces

- Configurable lifting unit, operator handle, vacuum gripper and vacuum generator

- Workpieces can be swiveled by 90° (optional with JumboErgo PSE)

- Workpieces up to 300 kg