Everyone knows that no one can lift 300 kilograms on their own. But very few people are aware that even smaller weights can put a lot of strain on our musculoskeletal system. Yet employees in logistics lift a total of several tons a day. We want to relieve them of this burden.∼ Mattias Lindh, Head of Business Area Handling

Basics of ergonomics

Basics of ergonomics

Healthy and productive work

Ergonomics is a topic that is present everywhere. The term comes from the Greek and refers to the optimal interaction between people and the working environment. What does an ergonomically designed workplace look like? What role does ergonomics play in the health of employees? And what does ergonomics have to do with a shortage of skilled workers? At Schmalz, we deal with these fundamentals of ergonomics on a daily basis. And we develop solutions so that work adapts optimally to people. Not the other way around. We would be happy to share our work and experience with you.

Ergonomics - what does that actually mean?

Ergonomics is a linguistic construct composed of the ancient Greek words "ergon" (work) and "nomos" (law). The modern meaning of the term originated in Poland: In 1857, the researcher and professor Wojciech Jastrzębowski formulated the "Outline of Ergonomics" and thus founded the science of work based on scientific findings. The goal: to create optimal conditions for fatigue-free work. This refers to the environment as well as to actions and processes. Today, the term comprises not only physical but also cognitive aspects - and thus takes into account everything that is tangible, but also content-related aspects such as monotony, multitasking and pressure to perform. Ergonomics is one of the four pillars of manual handling, along with safety, productivity and sustainability.

Prevention and occupational safety

What do safety shoes, floor markers and therabands have in common? They ensure that people stay healthy – whether through external protection or physical fitness. In the area of physical work, the legislator takes over this protective and preventive function.

In August 1996, the new Occupational Safety and Health Act (ArbSchG) came into force in Germany. It regulates the duties and rights of employers and employees with regard to occupational safety and health, as well as their monitoring. The aim of the ArbSchG is to prevent accidents and illnesses at work and to make work humane. To this end, the employer or a competent person appointed by him is obliged to carry out a risk assessment in order to derive necessary occupational safety measures from it.

All employers and employees who have to manually lift, carry, move, pull, push or set down loads at work come into contact with the Load Handling Ordinance (LasthandhabV) within the framework of the ArbSchG. As soon as defined guideline values are exceeded in the process, measures must be taken to protect the health of employees in accordance with the Occupational Health and Safety Act. The reference characteristic method helps to determine and evaluate the actual physical workloads by taking into account aspects such as weight, exercise duration or posture.

Lifting and carrying loads

The maximum weight that a person may lift and carry per operation during a work shift is formulated in EU Directive 90/269/EEC. In this context, the age and gender of the worker as well as the frequency of the work operation play an important wheel.

| Activity | Gender | Age in years | Reasonable load in kg depending on frequency per shift | |

|---|---|---|---|---|

| occasionally < 5% | frequently > 10% | |||

| Lifting/carrying | Men | 15 - 18 | 35 kg | 20 kg |

| 19 - 45 | 55 kg | 30 kg | ||

| > 45 | 45 kg | 25 kg | ||

| Women | 15 - 18 | 15 kg | 10 kg | |

| 19 - 45 | 15 kg | 10 kg | ||

| > 45 | 15 kg | 10 kg | ||

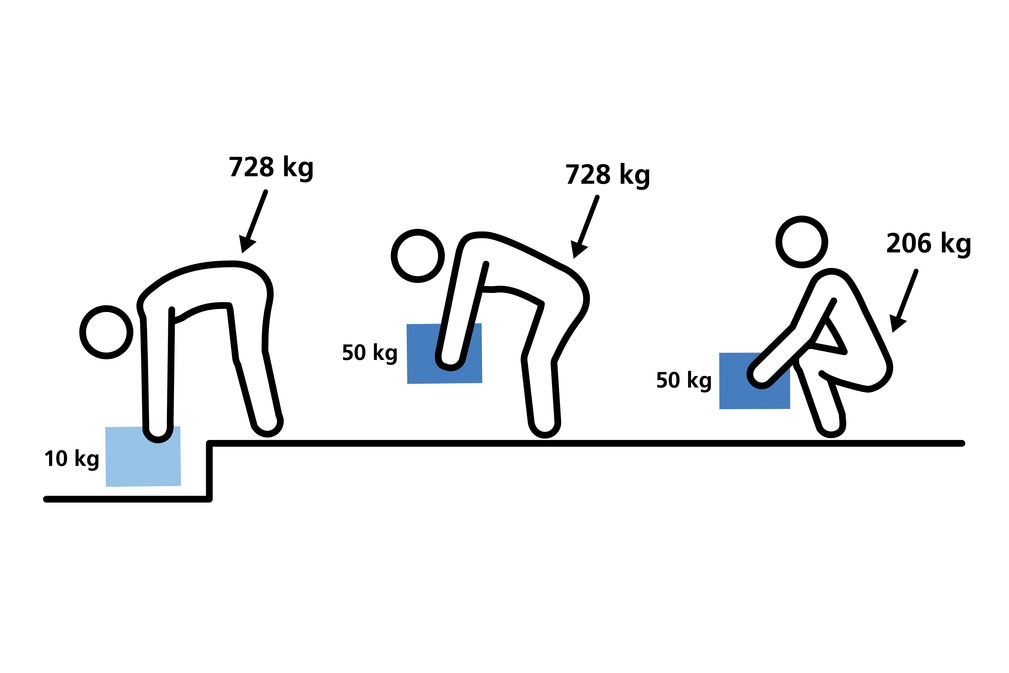

Correct posture is equally important for ergonomically correct work. This is because the further away the load is from the body's center of gravity, the more strenuous it is to lift and carry. The "effective load" indicates the weight force that a person actually has to exert when handling a load.

Basic pillars of manual handling

Vacuum lifters help companies fulfill their duty of care as defined by the Occupational Health and Safety Act. They create healthy working conditions and minimize the risk of damage to health when lifting and carrying loads. But there is more to healthy lifting than ergonomics. At Schmalz, we have defined the following four pillars for the successful use of lifting aids. In addition to ergonomics, these are safety, productivity and sustainability.

Our vacuum lifting devices comply with current safety standards and guidelines – and in many cases even exceed them. A clear color and symbol language, intuitive operating concepts and audible warning signals prevent operating errors.

Safety has a positive effect on productivity. Because safe and ergonomically designed work results in constant performance. Our lifting aids are so sensitive that the user can place the workpieces precisely. The gripping principle with vacuum also protects the surfaces of the workpieces and prevents damage.

Sustainability is a high priority at Schmalz: Our products are of high quality and designed for a long service life. In production, we rely on the use of regenerative energies, energy-saving production processes and the use of separable, recyclable materials. Wear parts are easily replaceable. For sustainable operation, we offer vacuum generators with different suction capacities and a radio remote control for switching the devices on and off.

Excellent ergonomics: The AGR seal of quality

Ergonomically designed work equipment is an important tool in the prevention and therapy of musculoskeletal disorders. The Aktion Gesunder Rücken (AGR) e.V. (campaign for a healthy back), in cooperation with the two largest German back training associations, has established a seal of approval that serves as an orientation aid in the procurement of work equipment, for example. All products bearing the seal of approval have undergone a detailed award procedure.

Vacuum lifting devices from Schmalz have been certified with the AGR seal of quality. An independent panel of experts from various medical fields confirms that vacuum lifting devices promote lifting loads in an ergonomically correct posture and enable users to work in a way that is gentle on the spine and back. In addition, they motivate the user, speed up work processes and minimize sick leave and absences from work.

Contact

Taivaltie 5

FI-01610 Vantaa

Ergonomics put into practice

Further information on the subject of ergonomics

Der Greifer macht den Unterschied

Wie vielfältig der Schlauchheber JumboFlex ist, zeigt ein Rundgang durch die Produktionshallen der Aliaxis Deutschland GmbH. Gleich mehrere Vakuumheber und Krane erleichtern die tägliche Arbeit.

Der Möbelpacker zum Aufgabeln

JYSK will, dass es den Mitarbeitenden gut geht. Um Rückenschmerzen vorzubeugen, erleichtert der mobile JumboFlex Picker die Kommissionierung im Logistiklager.

Ergonomisches Gesamtkonzept

Für das Textil-Verteilzentrum von dm-drogerie markt entwickelte Schmalz ein effizientes Gesamtkonzept, das den ergonomischen Anforderungen bei steigendem Arbeitsvolumen gerecht wird.

Weitere Informationen zum Gütesiegel

Geprüft und empfohlen vom Forum: Gesunder - Rücken - besser leben e.V. und dem Bundesverband deutscher Rückenschule (BdR) e.V. Eine Übersicht aller geprüften Schmalz Produkte sowie weitere Infos zum Gütesiegel bei: AGR e.V., Stader Str. 6, 27432 Bremervörde, Tel. 04761/92 63 580, www.agr-ev.de