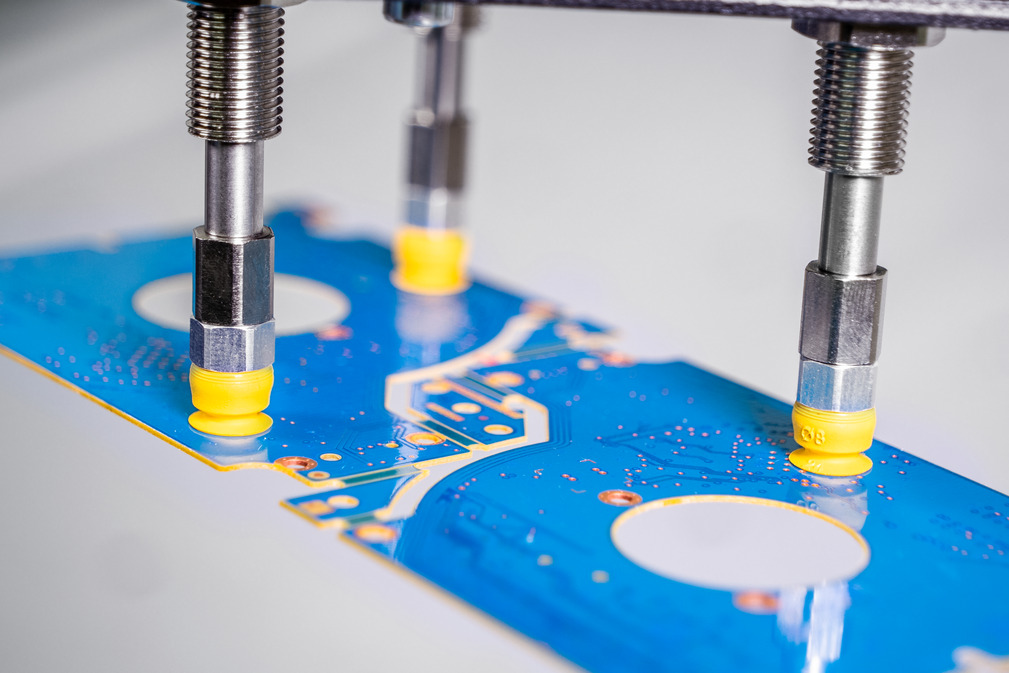

Flat Suction Cups SUF

- Diameter: 1 to 30 mm

- Material: NBR, NBR-ESD, SI, SI-CO, HT1

- Conductive, dissipative and mark-free variants

With increasing digitization and connectivity in almost every industry, not only the demand for electronic components is increasing, but also their complexity. In the automotive, consumer electronics (handsets), infrastructure and aviation sectors, for example, the demands placed on parts and components are constantly increasing. New production technologies and miniaturization are the results.

In the semiconductor sector, increasingly better and more powerful chips are manufactured, which are further processed in complex processes in the packaging sector. Due to the steadily decreasing form factor, PCB manufacturers and developers are required to generate more complex circuits and to manufacture them reliably. The high demand for electronic devices also requires manufacturers in all areas to improve their processes, increase throughput and achieve YIELD increases. Automation and information processing are part of this process. Safe and sensitive handling of components and products within the process chain are becoming increasingly important.

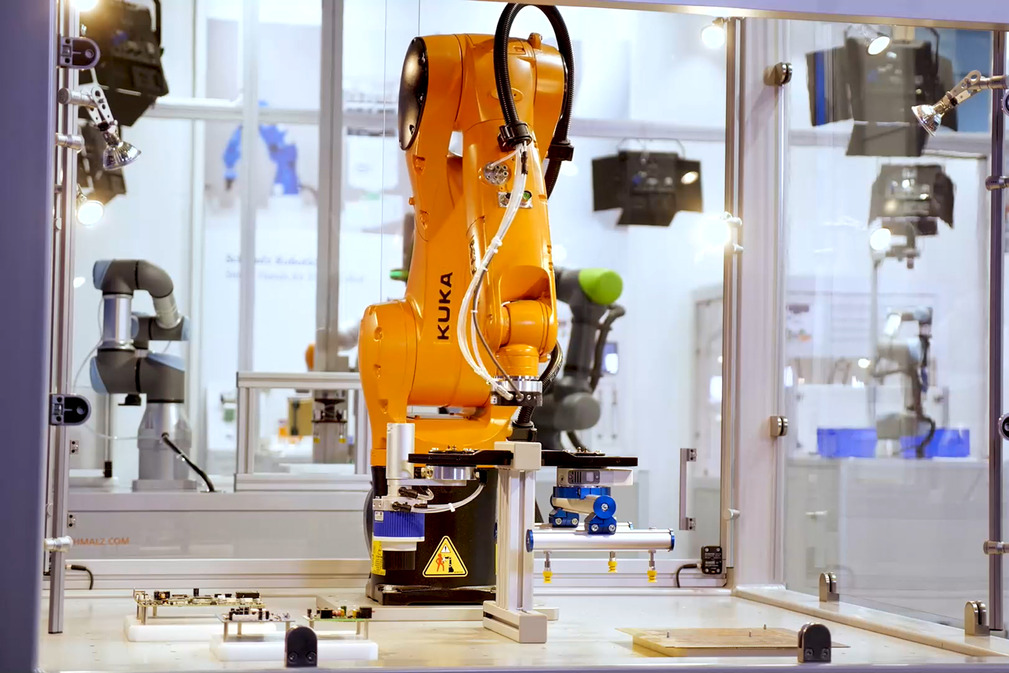

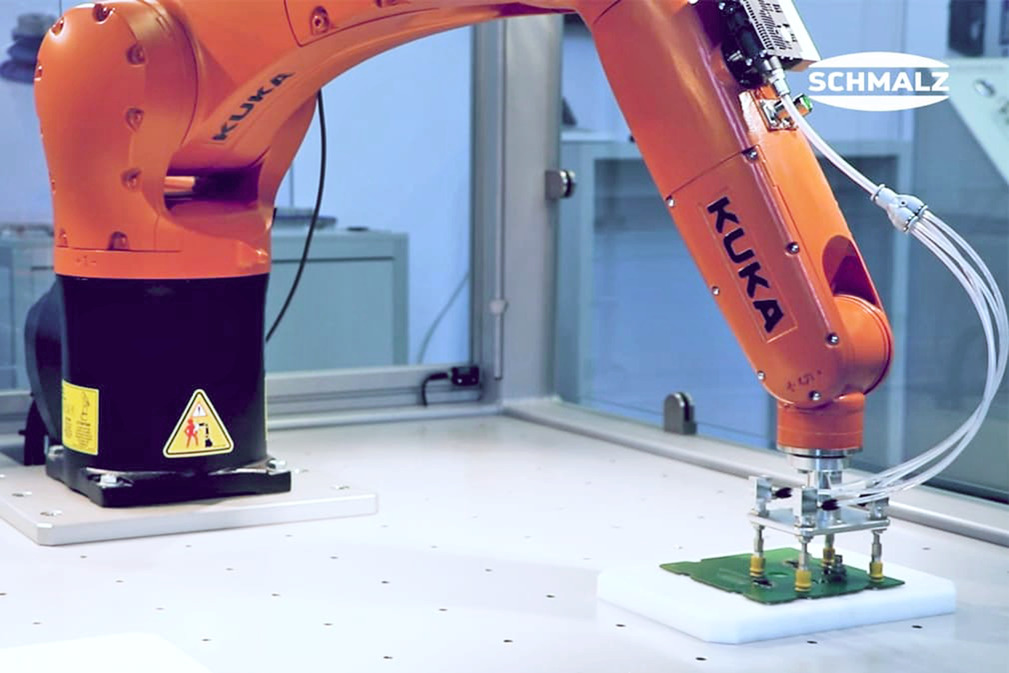

Vacuum technology and the associated vacuum systems make it possible to meet the requirements. Thanks to Schmalz's expertise in the field of vacuum technology and the associated knowledge of the electronics industry, Schmalz can offer the right solutions for the most advanced processes. In addition, new products are constantly being developed to meet the increasing requirements in the individual areas of semiconductor, printed circuit board and end product production.

New

Sensitive Electronics Perfectly Handled – Minimized Marks, Maximized ESD Protection

In electronics manufacturing, there is no second chance. One tiny mark, one static discharge and entire batches are ruined. Not with us!

Our innovative suction cups made the material of HT1-ESD solve these challenges and many more: They protect workpieces from unwanted marks and ESD damage. With our suction cups, you benefit from:

Thanks to our extensive expertise in material development, the suction cup material HT1-ESD stands for cutting-edge technology and sets new standards in electronics manufacturing.

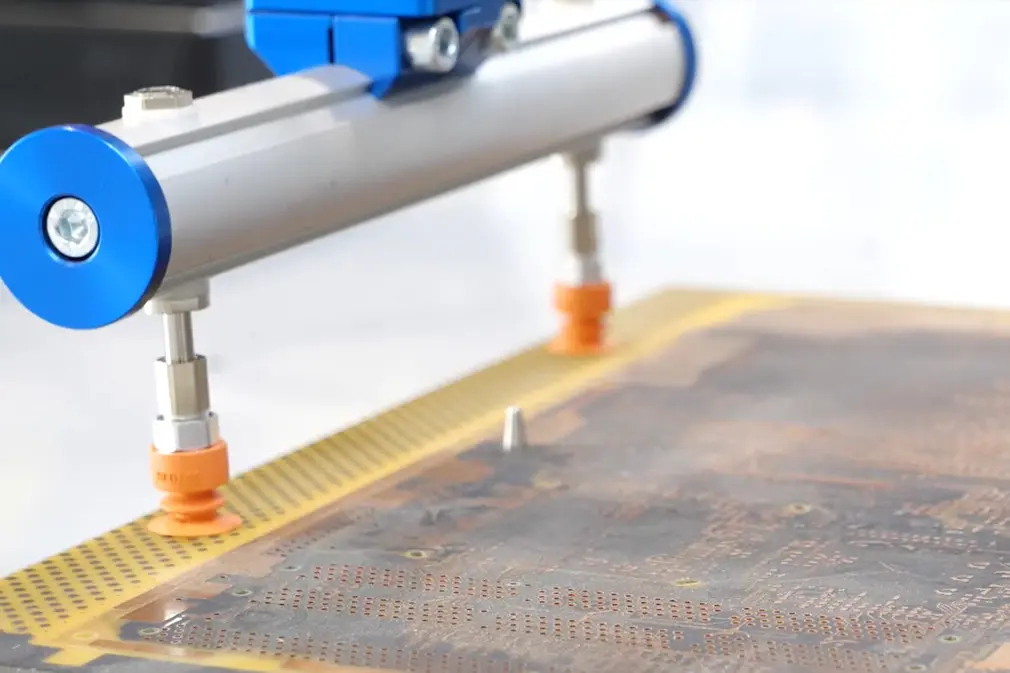

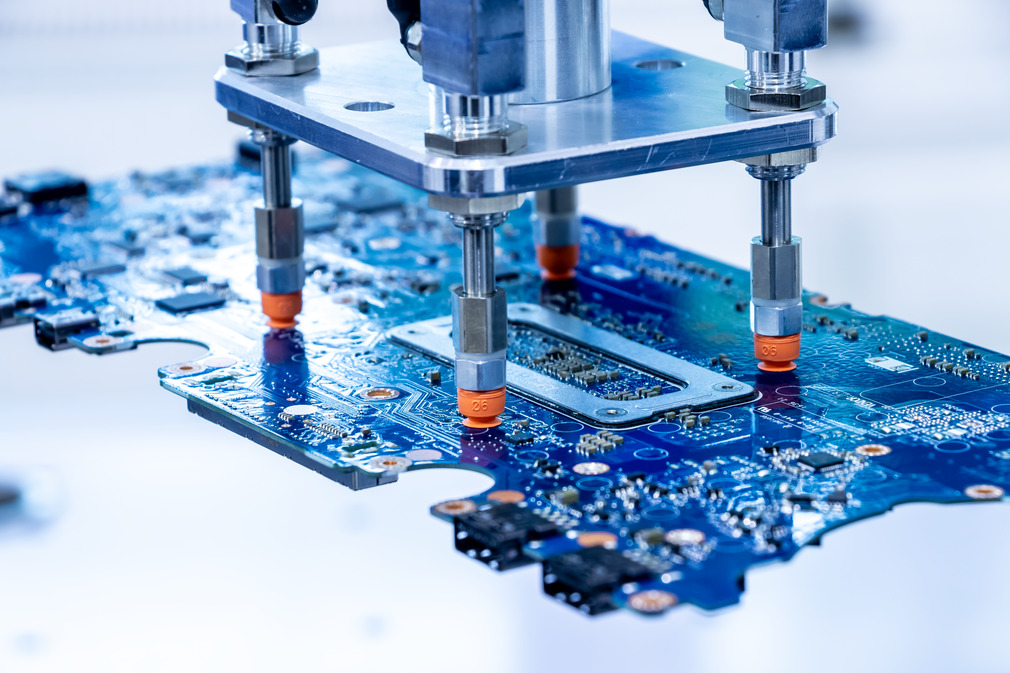

The active areas of the printed circuit board are highly sensitive, therefore the PCBs are handled at the outermost edge. As a result, Schmalz recommends the use of suction cups with a diameter of less than 15 millimeters from the PFYN, FSGA or FSG product families. The use of a spring plunger for height compensation from the FSTIm product family supports safe handling. In combination with a flat suction cup like the SGON, this results in a solution that masters even the most difficult requirements and load cases.

In the field of PCB manufacturing, environmental influences should not be underestimated. Schmalz offers a wide variety of materials in combination. The product portfolio includes suction cups made of low-impression HT1 material as well as NBR-ESD material for the safe discharge of generated charges.

Thanks to the individually adaptable solutions from Schmalz, handling and process steps can be made safer and rejects minimized.

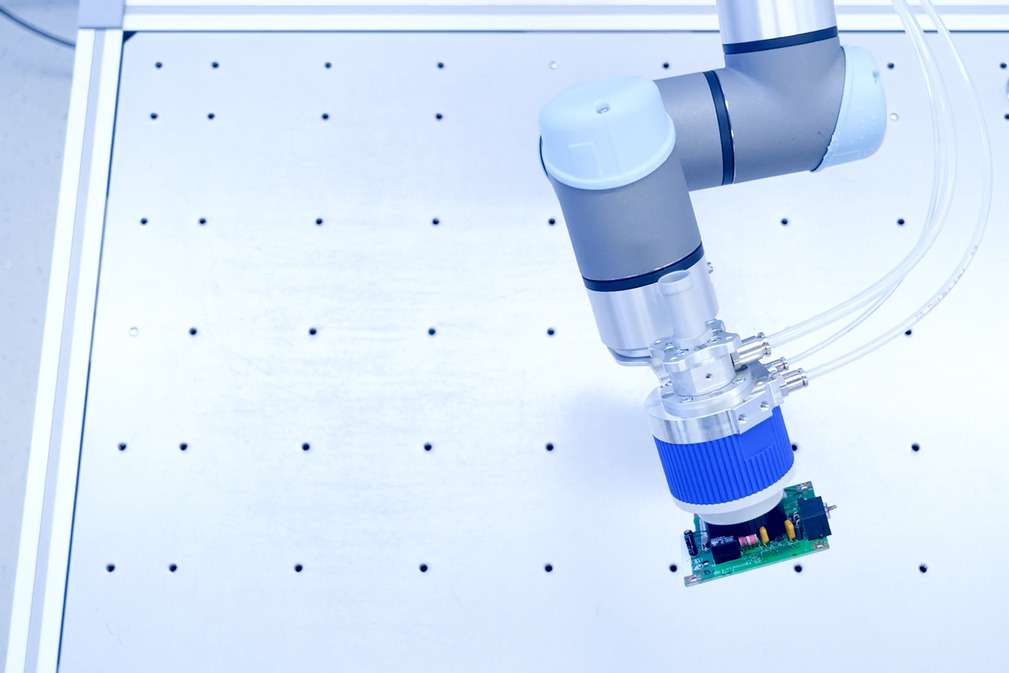

Due to the diversity and countless geometries of an assembled printed-circuit board, a PCB handling solution is required that compensates for the height differences of the components while also preventing damage due to mechanical stress. Thanks to its extremely high flow rate, the Schmalz flow gripper SCG is ideal for handling circuit boards and uneven components. The sealing lip adapts to the different geometries. The partially projecting solder tags used in the THT process create height differences that can be compensated by the floating suction cup SBS (based on the Bernoulli principle), thus enabling effective handling.

Vacuum technology is used not only in the assembly process itself, but also for the component supply station ("feeder") of the pick-and-place machines. Whether for the blister tape reels ("Tape&Reel") or the tray supply: Schmalz suction cups can be used to great effect in both areas. Schmalz also offers suitable products for larger components and for provision in plastic tubes.

Electrostatic Discharge: Requirements of Electrical Discharge Capacity

In the electronics industry, workpieces are often exposed to extreme stresses, particularly during manufacturing and handling processes. Mechanical or thermal stress is not the only cause of damage to components or materials.

Electrostatic charges and the resulting uncontrolled electrostatic discharge (ESD) produce irreversible damage to electrical, electronic, or optoelectronic components such as IC chips or printed-circuit boards.

Discover application examples of the product in various industries - user-friendly, informative and practical.

No suitable videos found? Then take a look at our media center.