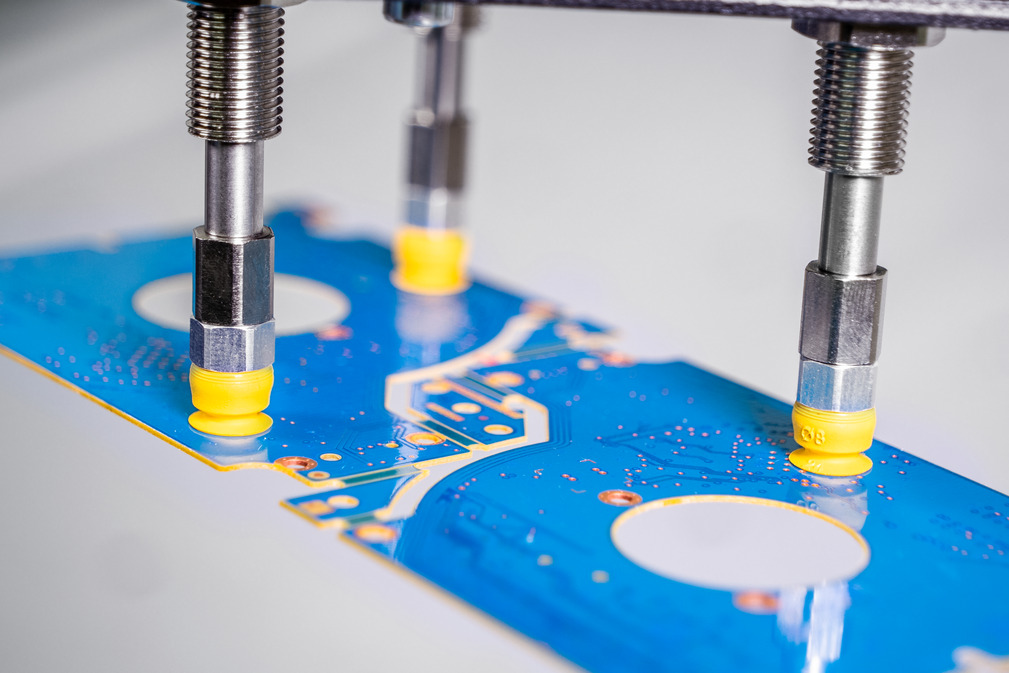

평평한 흡입 패드 SUF

- 직경 : 1 ~ 30mm

- 자료 : NBR, NBR-ESD, SI, SI-AS, HT1

- 전도성, 분 산성 및 낮은 임프린트 변형

With increasing digitization and connectivity in almost every industry, not only the demand for electronic components is increasing, but also their complexity. In the automotive, consumer electronics (handsets), infrastructure and aviation sectors, for example, the demands placed on parts and components are constantly increasing. New production technologies and miniaturization are the results.

In the semiconductor sector, increasingly better and more powerful chips are manufactured, which are further processed in complex processes in the packaging sector. Due to the steadily decreasing form factor, PCB manufacturers and developers are required to generate more complex circuits and to manufacture them reliably. The high demand for electronic devices also requires manufacturers in all areas to improve their processes, increase throughput and achieve YIELD increases. Automation and information processing are part of this process. Safe and sensitive handling of components and products within the process chain are becoming increasingly important.

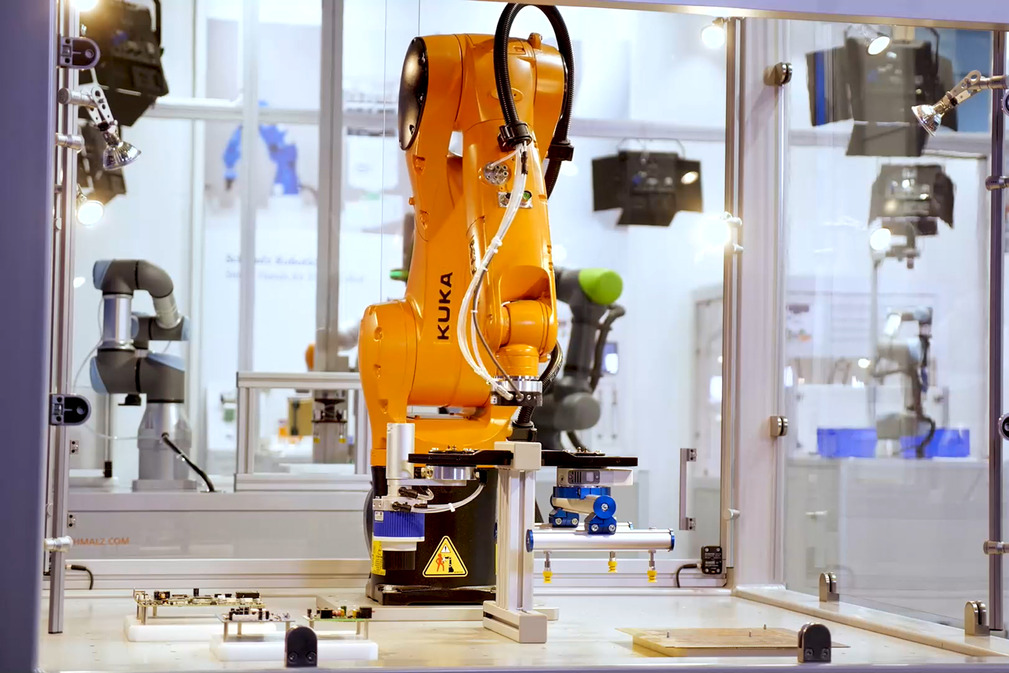

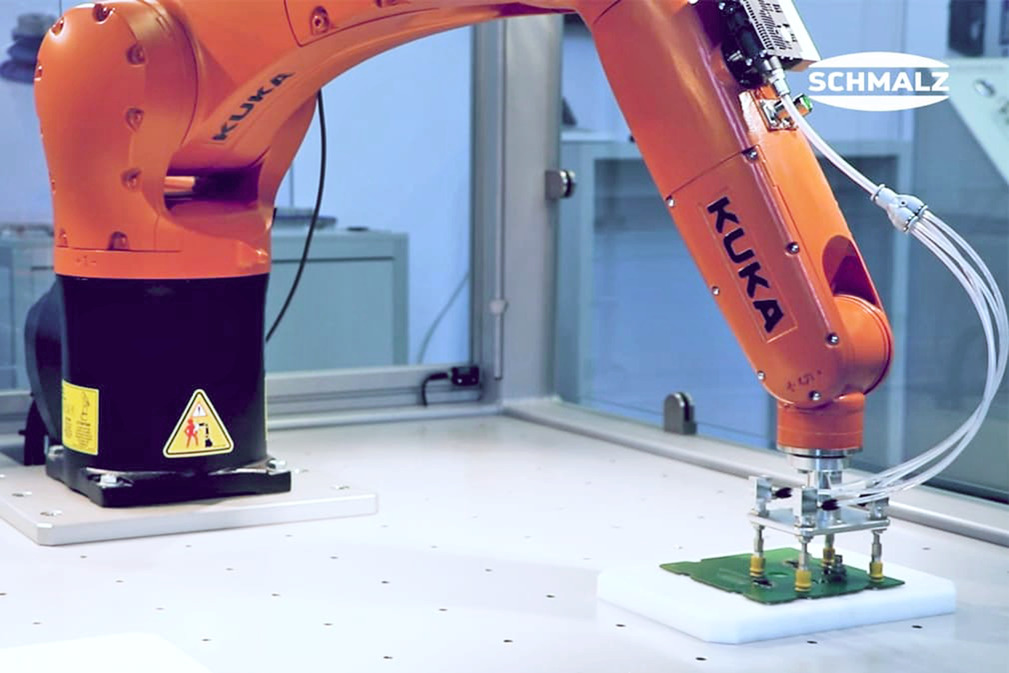

Vacuum technology and the associated vacuum systems make it possible to meet the requirements. Thanks to Schmalz's expertise in the field of vacuum technology and the associated knowledge of the electronics industry, Schmalz can offer the right solutions for the most advanced processes. In addition, new products are constantly being developed to meet the increasing requirements in the individual areas of semiconductor, printed circuit board and end product production.

새로운

민감한 전자 제품의 완벽한 핸들링 - 자국 최소화, ESD 보호 극대화

전자 제품 제조에는 두 번째 기회가 없습니다. 작은 자국 하나, 정전기 방전 한 번이면 전체 배치가 망가집니다. 저희는 그렇지 않습니다!

혁신적인 진공패드 재질로 만들어진 HT1-ESD는 이러한 문제를 비롯한 여러 가지 문제를 해결합니다: 원치 않는 자국과 ESD 손상으로부터 작업물을 보호합니다. 진공패드를 사용하면 다음과 같은 이점이 있습니다:

재료 개발에 대한 광범위한 전문성을 바탕으로 한 진공패드 재질 HT1-ESD는 최첨단 기술을 상징하며 전자 제품 제조의 새로운 표준을 제시합니다.

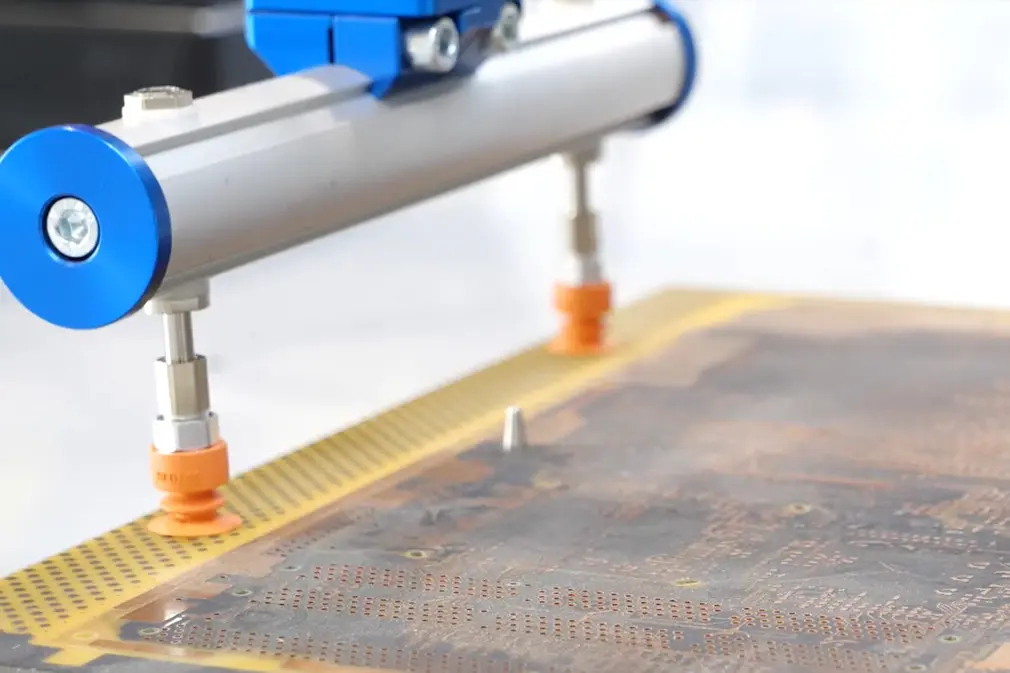

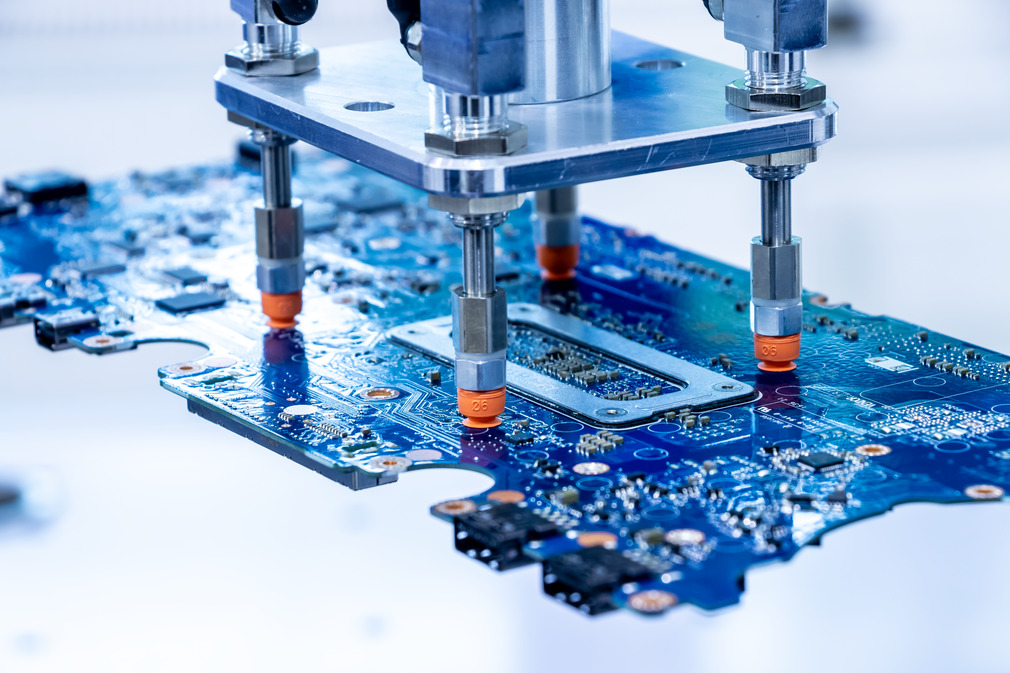

The active areas of the printed circuit board are highly sensitive, therefore the PCBs are handled at the outermost edge. As a result, Schmalz recommends the use of suction cups with a diameter of less than 15 millimeters from the PFYN, FSGA or FSG product families. The use of a spring plunger for height compensation from the FSTIm product family supports safe handling. In combination with a flat suction cup like the SGON, this results in a solution that masters even the most difficult requirements and load cases.

In the field of PCB manufacturing, environmental influences should not be underestimated. Schmalz offers a wide variety of materials in combination. The product portfolio includes suction cups made of low-impression HT1 material as well as NBR-ESD material for the safe discharge of generated charges.

Thanks to the individually adaptable solutions from Schmalz, handling and process steps can be made safer and rejects minimized.

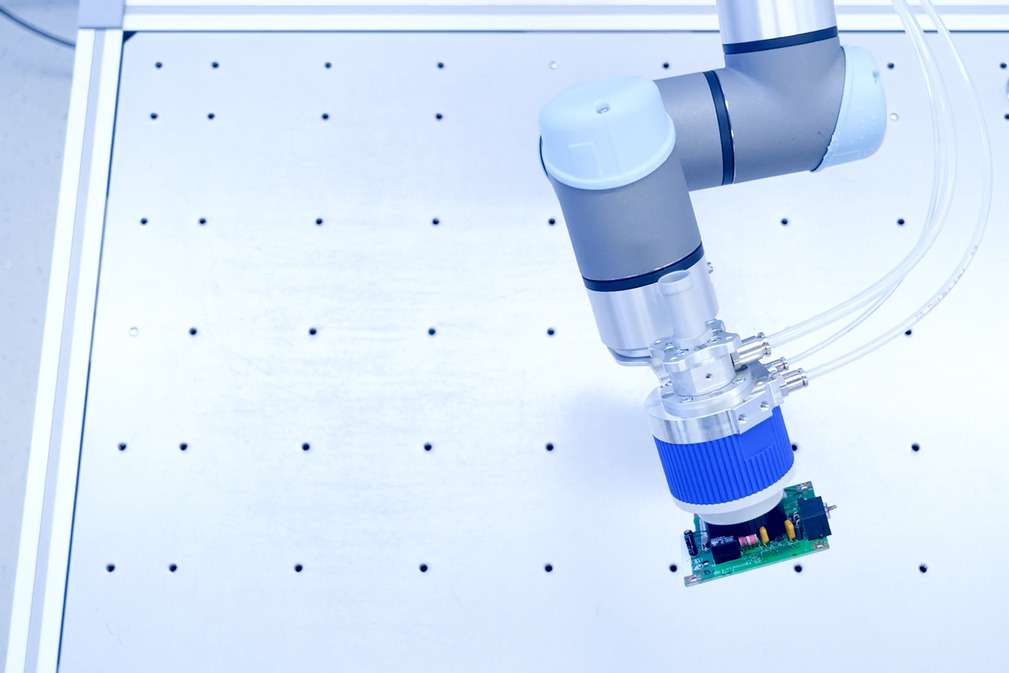

Due to the diversity and countless geometries of an assembled printed-circuit board, a PCB handling solution is required that compensates for the height differences of the components while also preventing damage due to mechanical stress. Thanks to its extremely high flow rate, the Schmalz flow gripper SCG is ideal for handling circuit boards and uneven components. The sealing lip adapts to the different geometries. The partially projecting solder tags used in the THT process create height differences that can be compensated by the floating suction cup SBS (based on the Bernoulli principle), thus enabling effective handling.

Vacuum technology is used not only in the assembly process itself, but also for the component supply station ("feeder") of the pick-and-place machines. Whether for the blister tape reels ("Tape&Reel") or the tray supply: Schmalz suction cups can be used to great effect in both areas. Schmalz also offers suitable products for larger components and for provision in plastic tubes.

정전기 방전: 정전기 방전: 방전 용량 요구 사항

전자 산업에서 작업물은 특히 제조 및 취급 공정 중에 극심한 스트레스에 노출되는 경우가 많습니다. 기계적 또는 열적 스트레스만이 부품이나 재료 손상의 유일한 원인은 아닙니다.

정전기와 그로 인한 제어되지 않은 정전기 방전(ESD)은 IC 칩이나 인쇄 회로 기판과 같은 전기, 전자 또는 광전자 부품에 돌이킬 수 없는 손상을 일으킵니다.

사용자 친화적이고 유익하며 실용적인 다양한 산업 분야의 제품 적용 사례를 발견하십시오.

적합한 동영상을 찾지 못하셨나요? 그렇다면 미디어 센터를 살펴보세요.