Digital Twin

A digital twin is a digital representation of a physical object, process or system in the digital world. It is a virtual model that is connected to data to realistically represent the behavior, functionality and processes of the object.

The digital twin builds a bridge between physical and virtual reality through the continuous exchange of data and information. It does not matter whether the physical object already exists or is still being planned. The digital twin is part of a cyber-physical system and maps the entire life cycle of a product or system. It can consist of various subtypes, such as the digital prototype, the digital instance or an aggregate of several twins.

Technologies behind the digital twin

The operation mode of a digital twin is based on continuous bidirectional communication between the physical object and its digital image. Sensors on the real object record data such as geometry, process variables, energy consumption, environmental conditions and kinematic and kinetic sizes.

This information is transferred to the digital model via IoT platforms and a standardized data structure such as the asset administration shell (AAS) and processed there. IoT platforms play a central role in data collection, transfer, integration and synchronization between the real object and the virtual model.

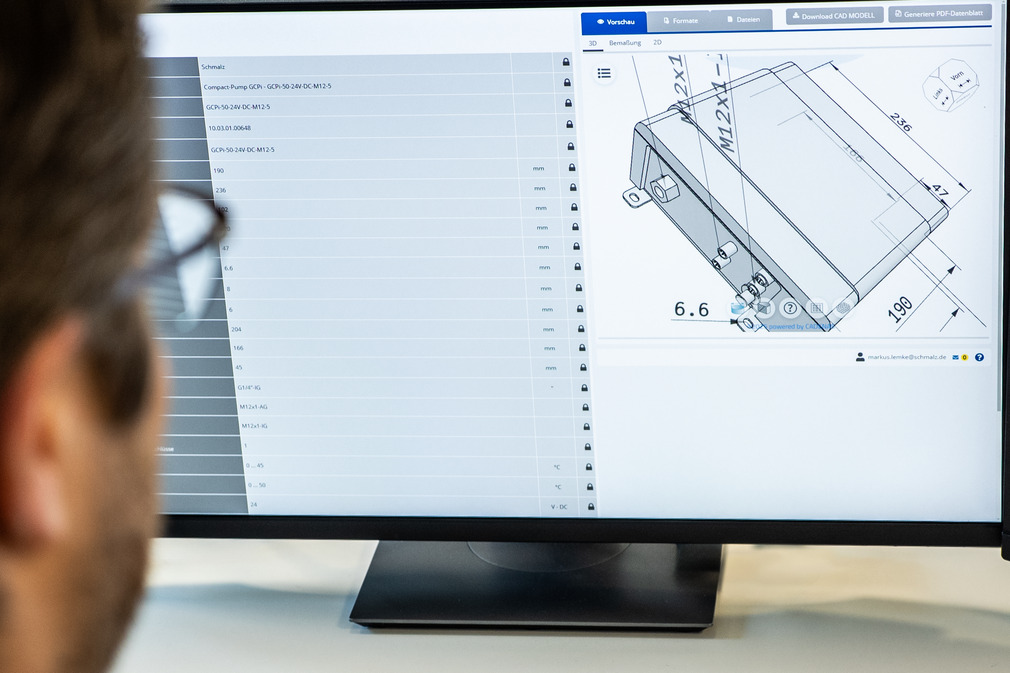

The digital model can be displayed as a 3D visualization to realistically depict structure, movements and forces. Algorithms, simulations and machine learning analyze the data, create forecasts and thus support the understanding of system behavior and decision-making.

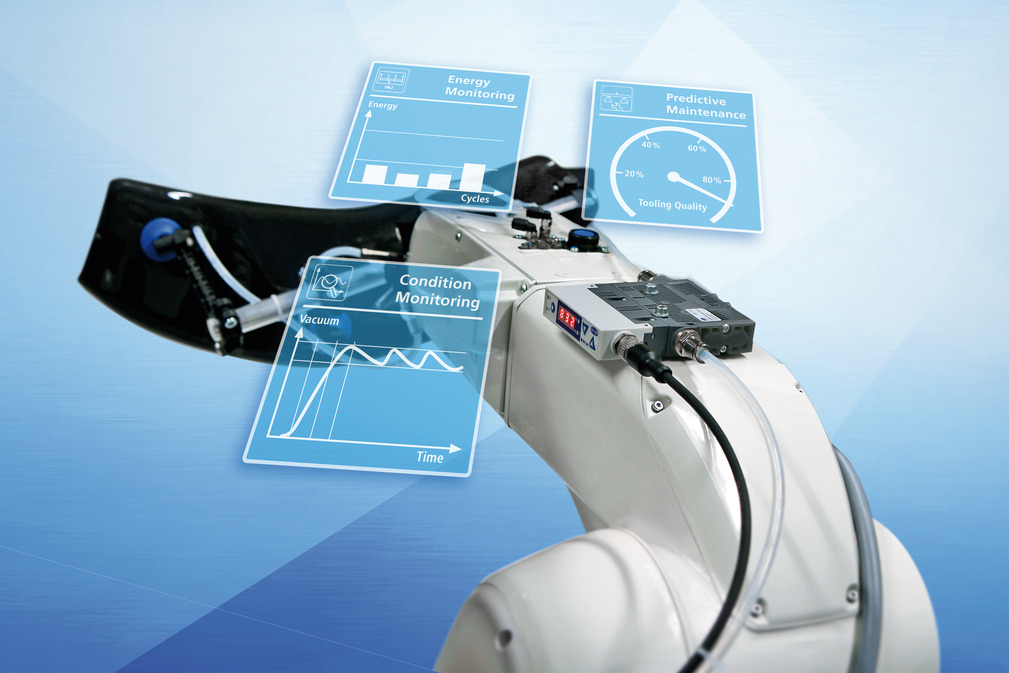

In this way, predictive maintenance, process optimization and even virtual start of operations can be implemented efficiently. Dashboards provide users and engineers with a clear, real-time view of all relevant information so that informed decisions can be made at any time.

Virtual start of operations and practical examples

The digital twin is primarily used in industrial production. Virtual prototypes are used to model production processes, test systems before they are actually implemented and optimize production planning.

A central use case is the virtual start of operations: even during the design phase, motion sequences of drives, signal processing from position measuring systems or end position sensors as well as control programs can be tested realistically in the digital model.

Digital twins are also used in supply chain management. They enable the monitoring of transport routes, the control of warehouse stocks and the planning of supply chains in real time.

In personalized medicine, digital images are used to create patient-specific models, such as digital heart models that simulate interventions or test implants.

The combination of digital twin platforms with artificial intelligence and control technology can be found in intelligent control systems, for example for predictive maintenance in aviation.

Digital twins as a key technology of Industry 4.0

Digital Twins increase efficiency, quality and added value along the entire product life cycle. Virtual start of operations (VIBN) allows machines, systems and processes to be digitally simulated, tested and optimized. Downtimes are minimized and deviations in implementation are avoided. At the same time, bottlenecks can be identified at an early stage and resources such as materials, personnel and machine capacities can be better planned.

This technology can also be used to analyze and predict the behavior of technical systems. It helps users to achieve error-free design of new systems, optimize the power of applications in the operating phase and reduce maintenance costs. It also supports the maximum reuse of materials at the end of life.

The combination of system data, simulation and predictive maintenance creates sustainable competitive advantages - from development to production and operation in the context of Industry 4.0.

Related terms

Digital Engineering

Faster, more flexible, more sustainable: experience how the classic art of engineering and state-of-the-art digital technologies come together - from virtual planning to the digital twin.

Digitalization

Seamlessly digital: Schmalz supports you with smart solutions along the entire life cycle.