Solution Kits ivOS Sheet Metal

The solution for handling sheet metal

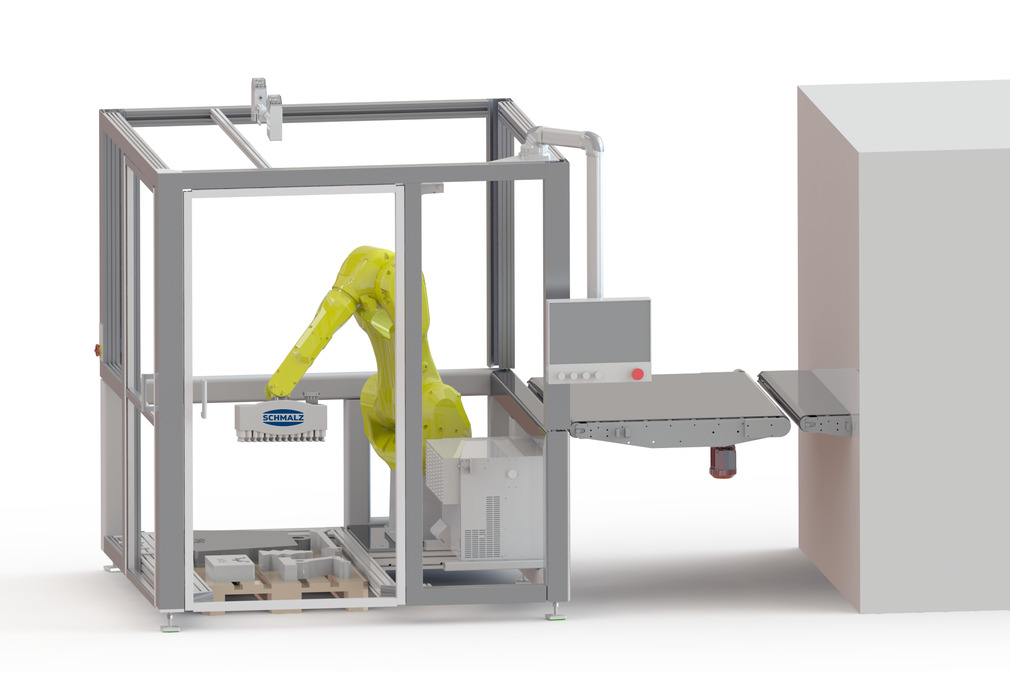

The Solution Kit is the optimal solution for automated handling of different sheet metals.

Efficient loading solution for existing and new plants

Individually controllable suction points enable automatic adaptation of the gripper to changing workpieces

Support of all common robots, sensors, pick software and interfaces

Flexible response to changing requirements and workpieces without teach-in process

The complete package includes CAD data, circuit diagrams and technical designs

Design

- Solution kits consisting of ivOS software package

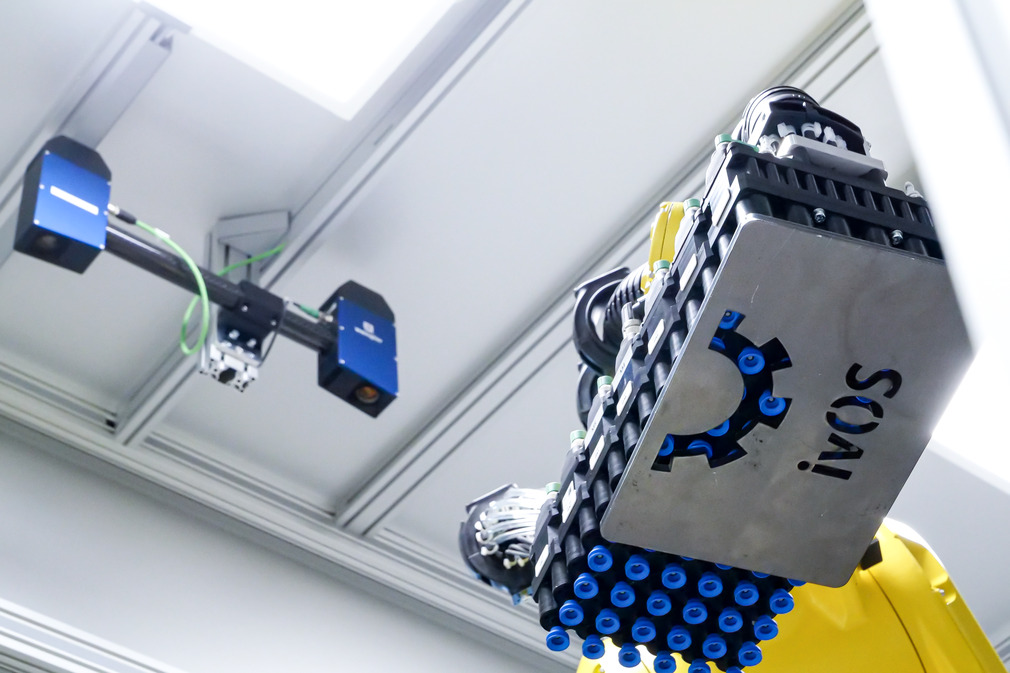

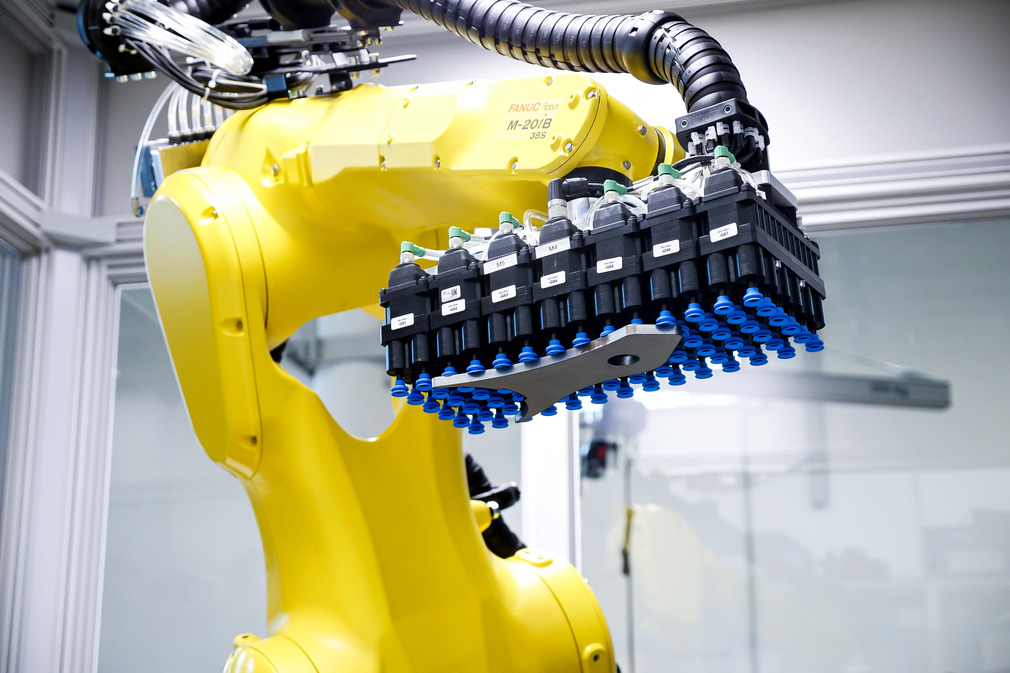

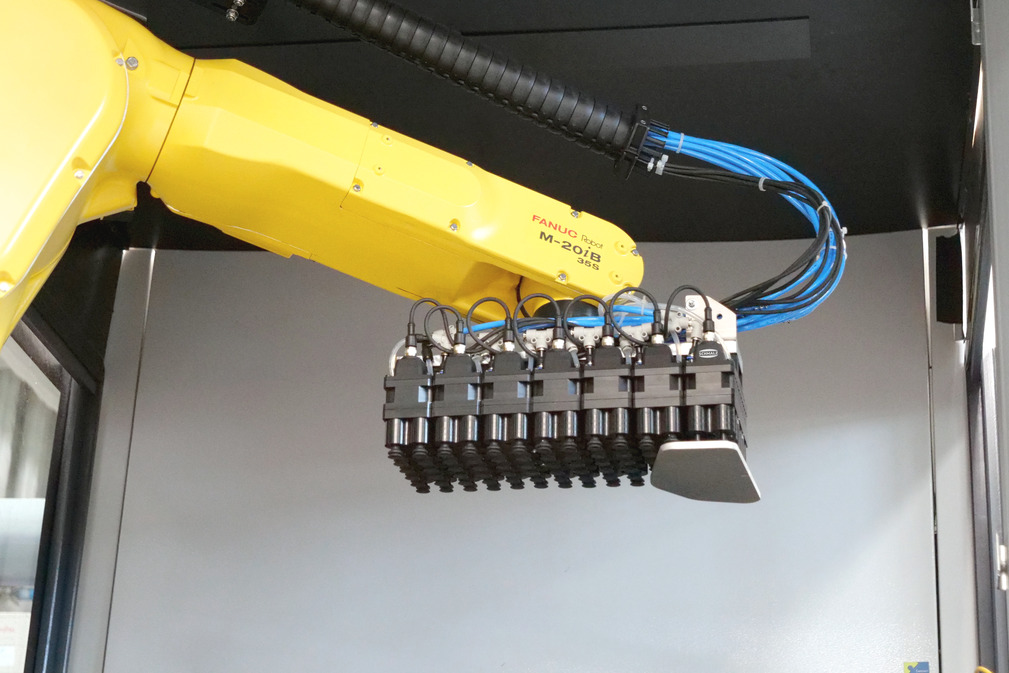

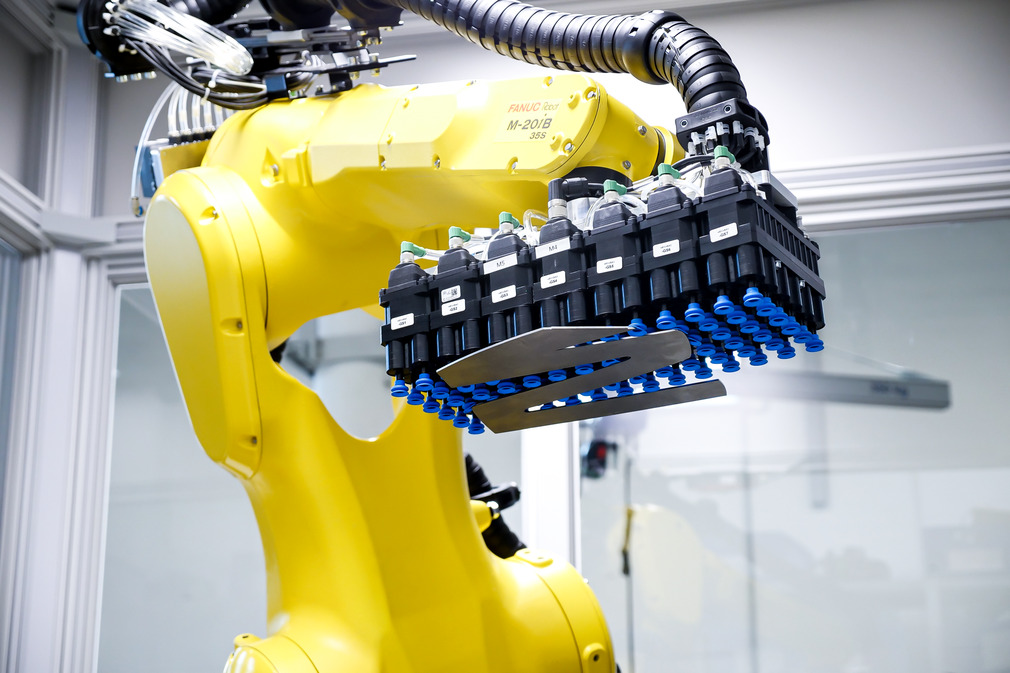

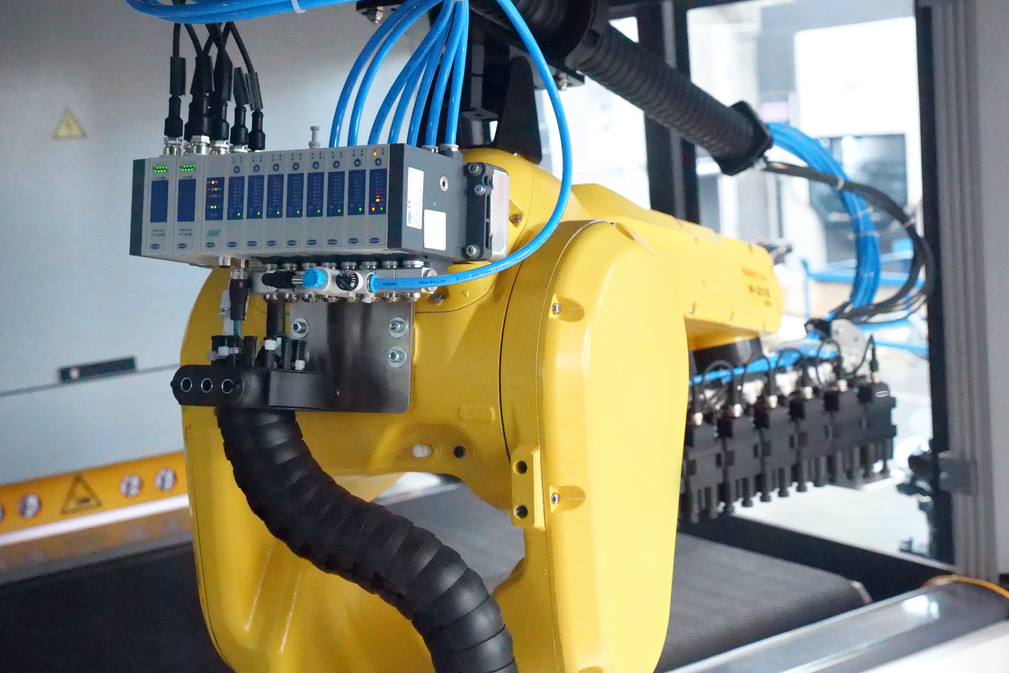

- Intelligent vacuum matrix gripper (1)

- 3D sensor (2)

Technical Data

- Loading of sheet metal processing machines

- Large workpiece variety

Documentation

The matching documentation for this product is available in this section.

| Documents | Language |

|---|---|

| English |

Integration

The technology: Vision Operating System ivOS

With ivOS, Schmalz has developed an operating system for bin picking. It enables integrators and OEMs to easily connect and control various components such as grippers, cameras, picking software and robots from different manufacturers. Thanks to modern interfaces, efficient data exchange in real time is possible, for example with warehouse management systems.

Open and flexible platform for integrators and OEMs

- High connectivity and high level of integration of all components

- Bring your own device: integration of own hardware and software possible

- Modules such as the pick software can be easily replaced for continuous improvement − even retroactively

Example configurations

Sheet Metal - powered by Schmalz Solution Kits

The ivOS Sheet Metal Solution Kit is a new, high-performance loading solution for grinding, deburring and bending machines in sheet metal processing. The special solution enables fully automatic system loading through the unique interaction of innovative gripper technology, modern 3D sensor technology and the latest algorithms for gripping point determination.

FACTS ABOUT THE USE CASE

- Gripping of up to 500 parts per hour

- No teach-in of new parts required, thanks to AI

- Gripper with individually controllable gripping points

- Load capacity up to 20 kg