Manufacturing of printed circuit boards: process steps and applications

| Process Step | Description | Vacuum Handling (Automation) | Process Vacuum |

|---|---|---|---|

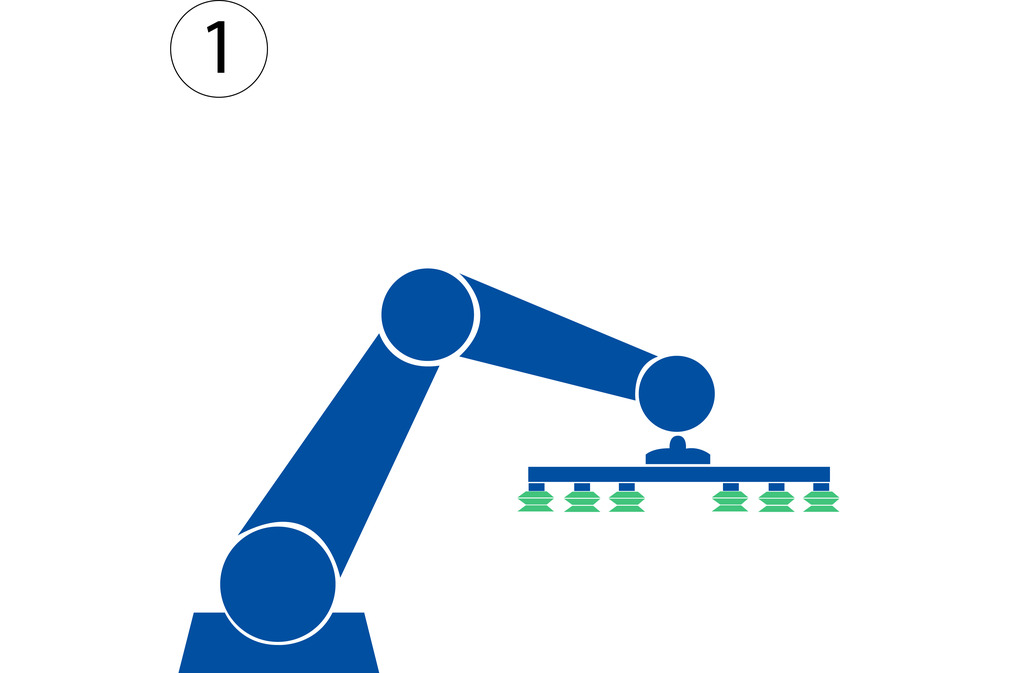

| 1 | Raw Material Handling | ✓ | |

| 2 | Drilling / Laser Drilling | ✓ | ✓ |

| 3 | Lamination | ✓ | |

| 4 | Exposure | ✓ | ✓ |

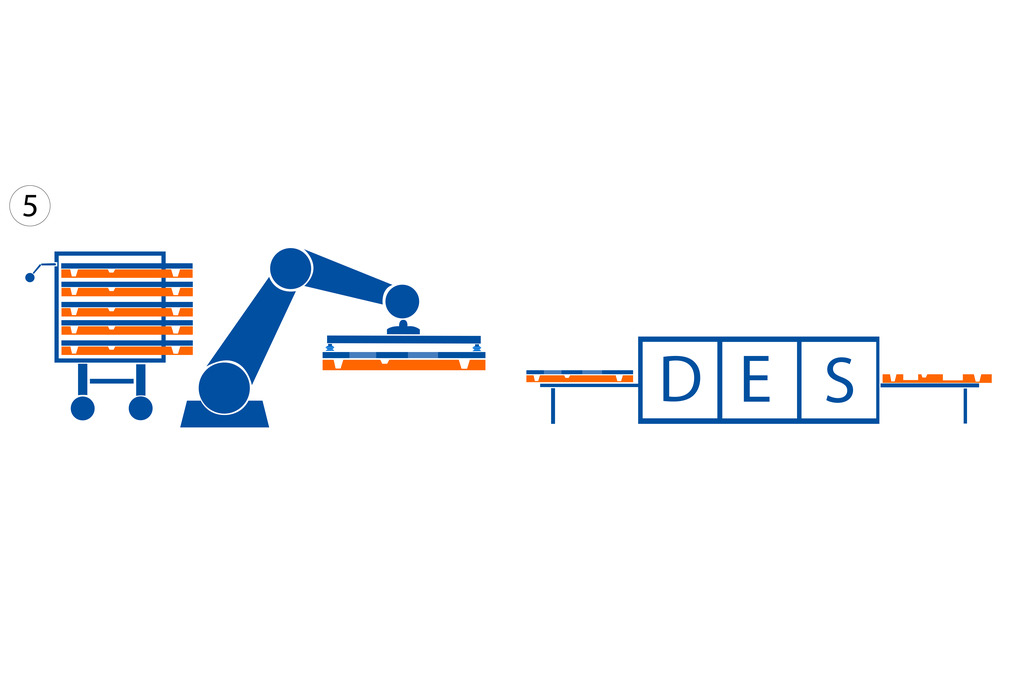

| 5 | Develop/Etch/Strip (DES) | ||

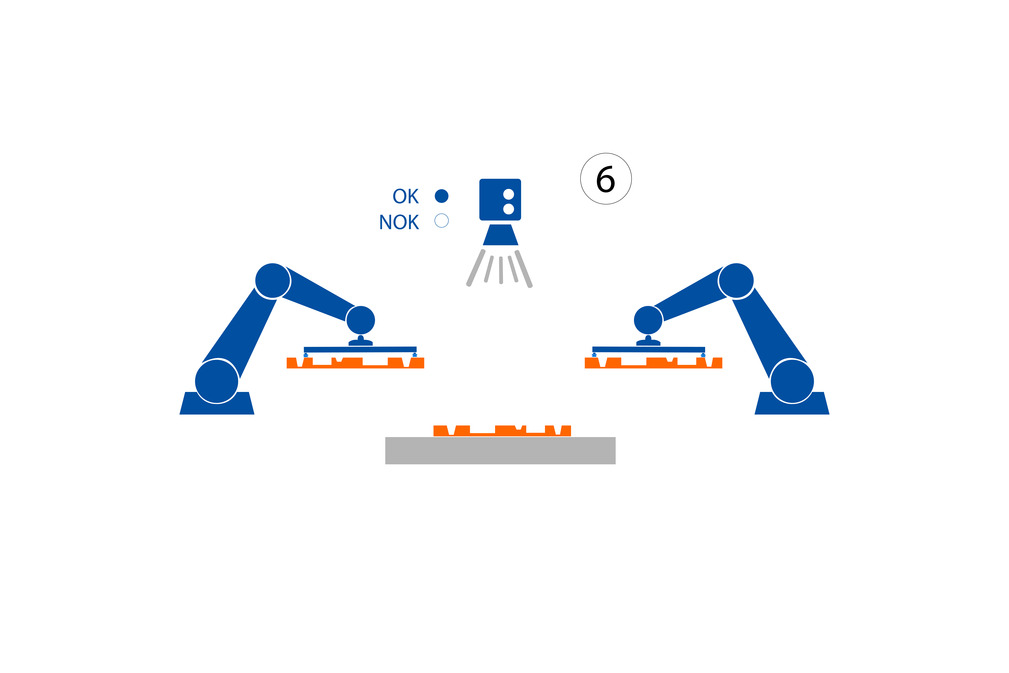

| 6 | Automated Optical Inspection (AOI) | ✓ | ✓ |

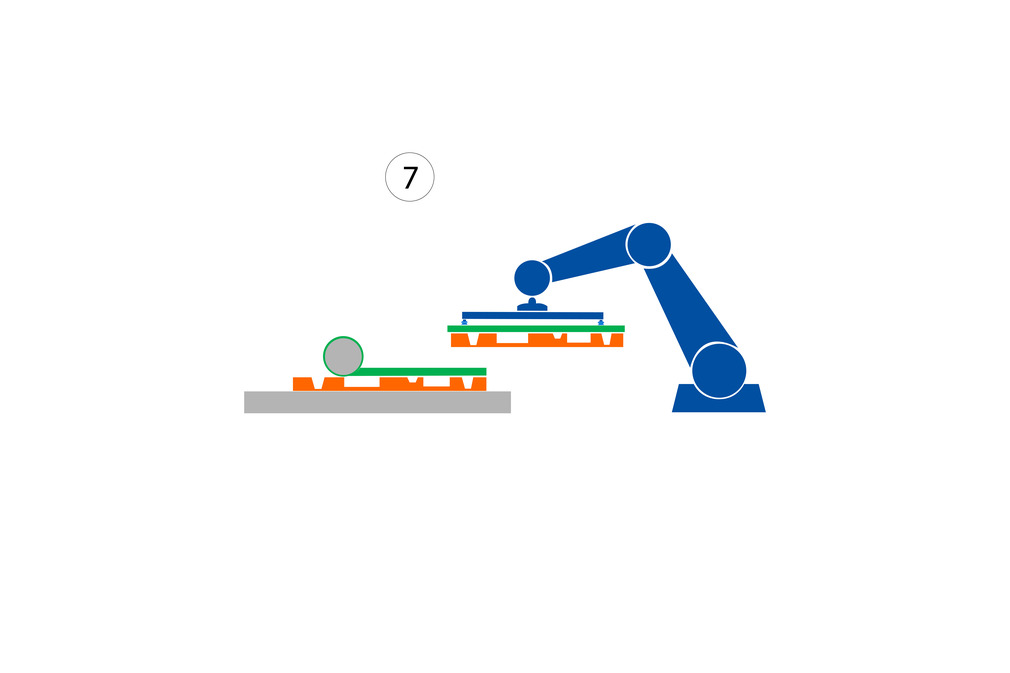

| 7 | Solder Mask | ✓ | |

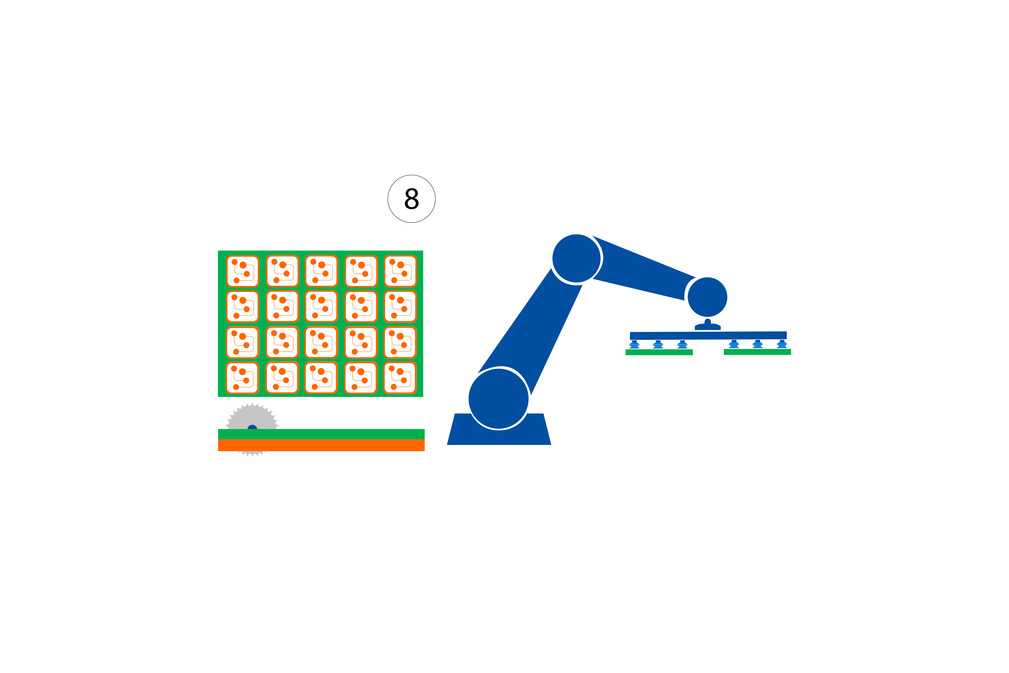

| 8 | Routing | ✓ | ✓ |

| 9 | E-Test | ✓ | ✓ |

In the following, you will learn more about the individual essential process steps that are necessary in the manufacturing of printed circuit boards. Different process steps have different demands on vacuum technology. Schmalz offers solutions for these requirements that enable safe handling.

A wide range of applications for vacuum technology during PCB manufacturing

Material preparation

The manufacturing of a printed circuit board (PCB) involves a large number of complex manufacturing processes. Differences in the PCB type influence the process chain and place further and very different requirements on handling and process.

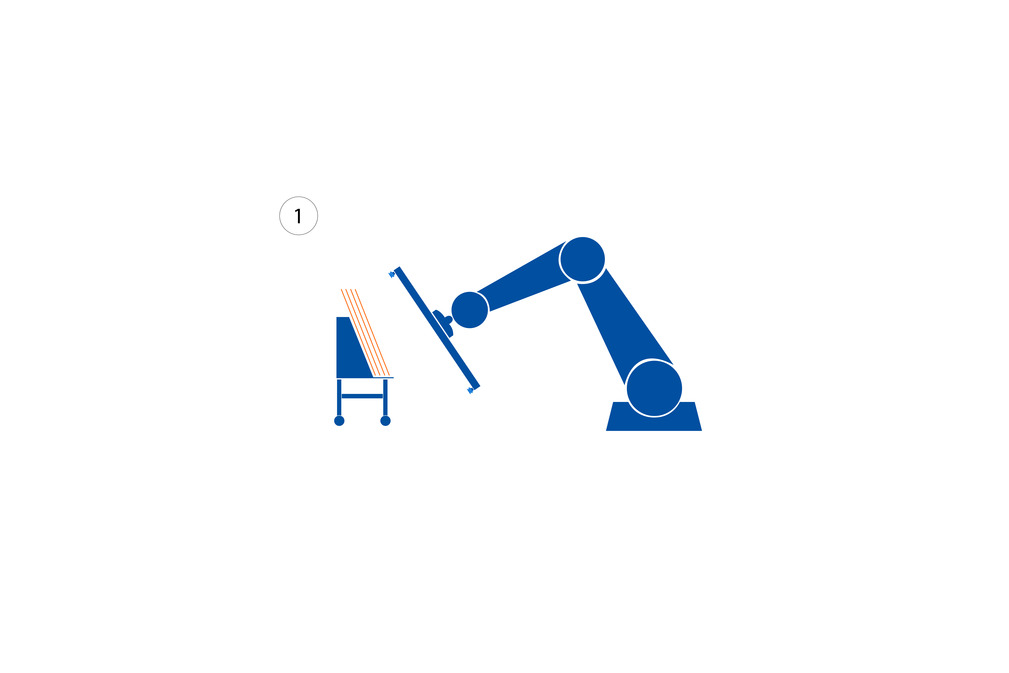

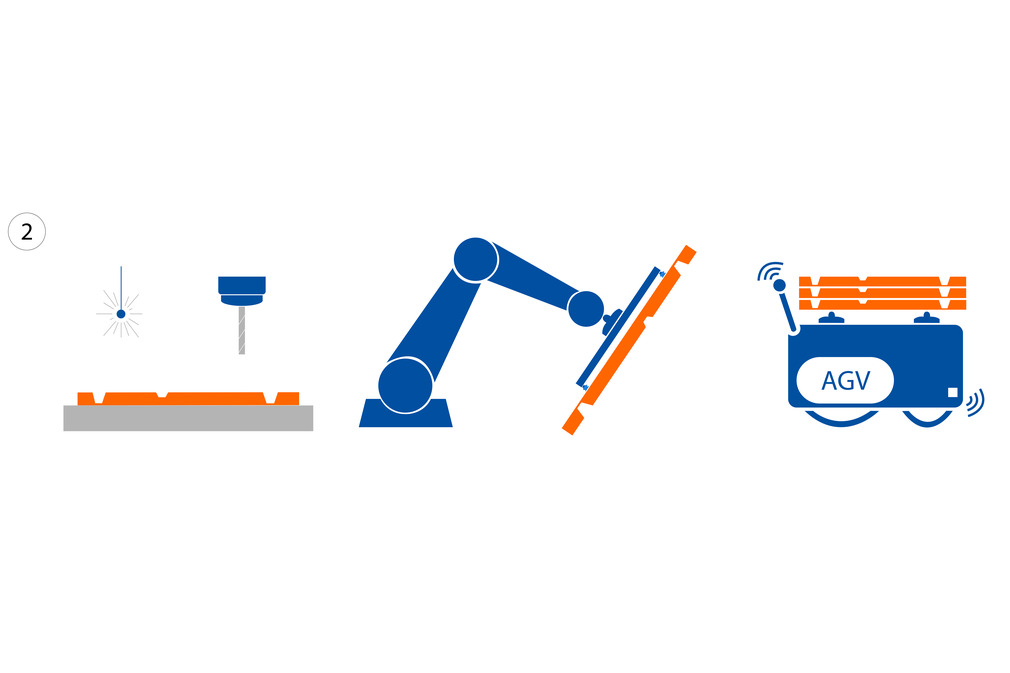

Based on the specification, corresponding raw material is provided for further processing (1). The raw material can be copper-coated FR4 material. In order to enable through-hole plating, the first step is to make contact holes using mechanical and laser drills (2). These are then further copper-plated to achieve conductivity through the FR4 material.

During these process steps, Schmalz products can be used, among other things, for handling the raw material.

Formation of the conductors

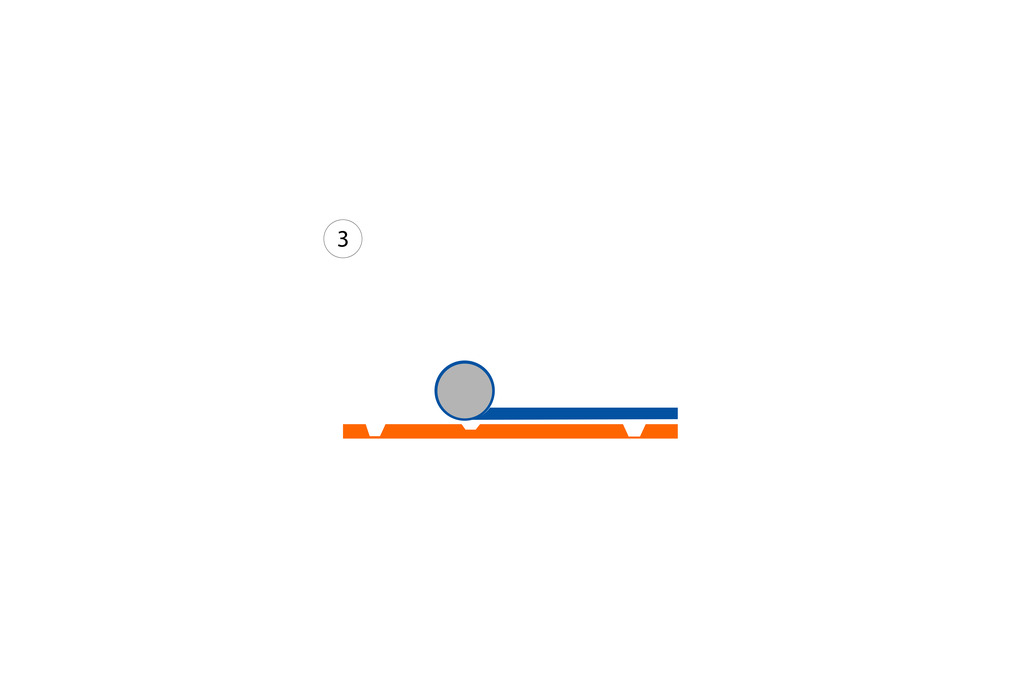

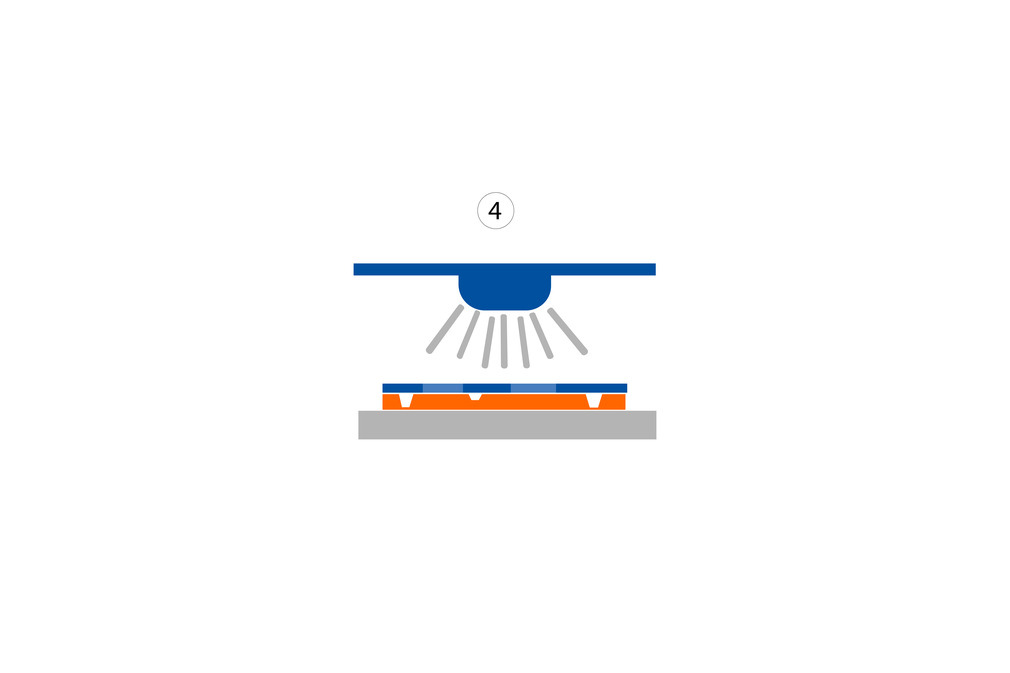

By laminating a photosensitive film (3), the prerequisites are created for predefining the desired layout and architecture. By using special exposure or direct imaging machines the desired line and spaces can be defined (4). The lamination and exposure process steps take place in cleanrooms to minimize the risk of contamination. Yellow light is also used. Depending on the properties of the lamination and mask, the desired structures harden during the exposure process. A sequence of wet-chemical processes is used to expose the conductors. In the first step of the Develop-Etch-Strip process (5), the unexposed and uncured areas of the film are washed off with an alkaline solution and the copper is exposed. In the etching process, the exposed copper is dissolved with the aid of an acid etching solution. In this process, the cured photo film serves as protection for the desired track structure. After cleaning the printed circuit board, the cured film is removed in the last process step with a combination of temperature and a strong alkaline solution. Now the copper conductor tracks are exposed and visible.

Fully automated processes in the production lines require safe handling. Vacuum components can be used to transport the PCB safely during the individual process steps.

Final finishing

In order to exclude errors in subsequent processes and before further processing, the processed printed circuit boards are optically inspected and faulty printed circuit boards are sorted out (6). Multilayer PCBs can be produced by pressing individual PCBs.

The application of the so-called solder mask (7) ensures that only the areas intended for the soldering of parts and components come into contact with solder and that the conductor paths are protected. Usually, the solder mask has a greenish colour, which gives the printed circuit board its typical appearance. The solder mask is only applied to the outer layers of a printed circuit board and completes the process chain.

Depending on the size of the end product, one PCB or "panel" contains several identical, self-contained and functioning PCBs. During the routing process (8) the end products are removed from the carrier/panel.

With an electrical test unit (9), the individual printed circuit boards are tested with the aid of electrical parameters. Finally, the finished and tested products are packed and sent for further processing.