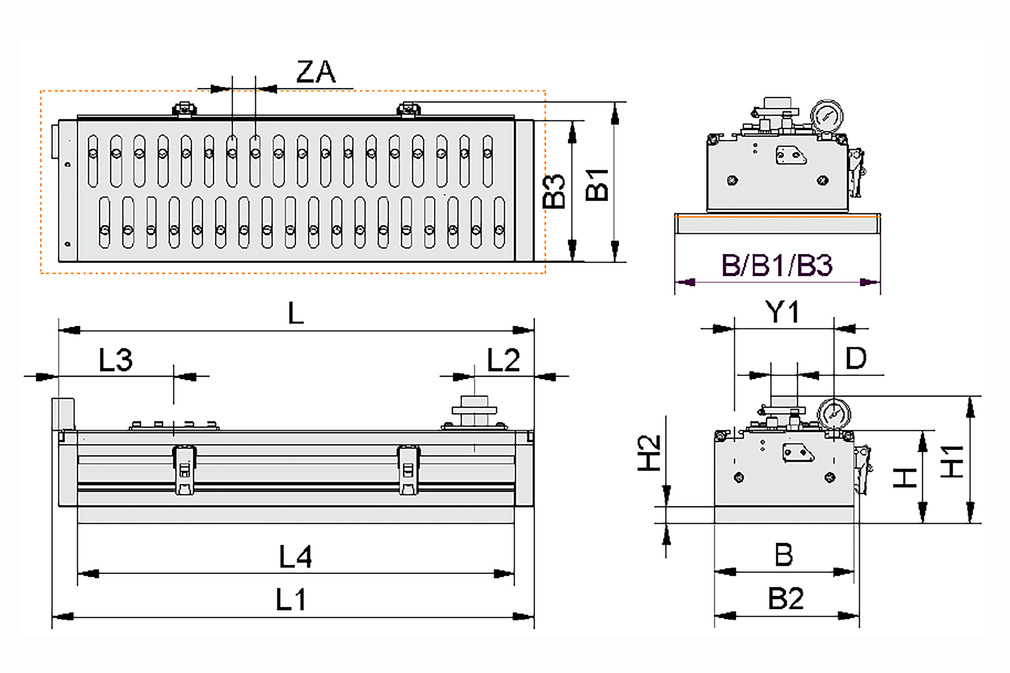

| Length L | 1050 (mm) |

| Width B | 170 (mm) |

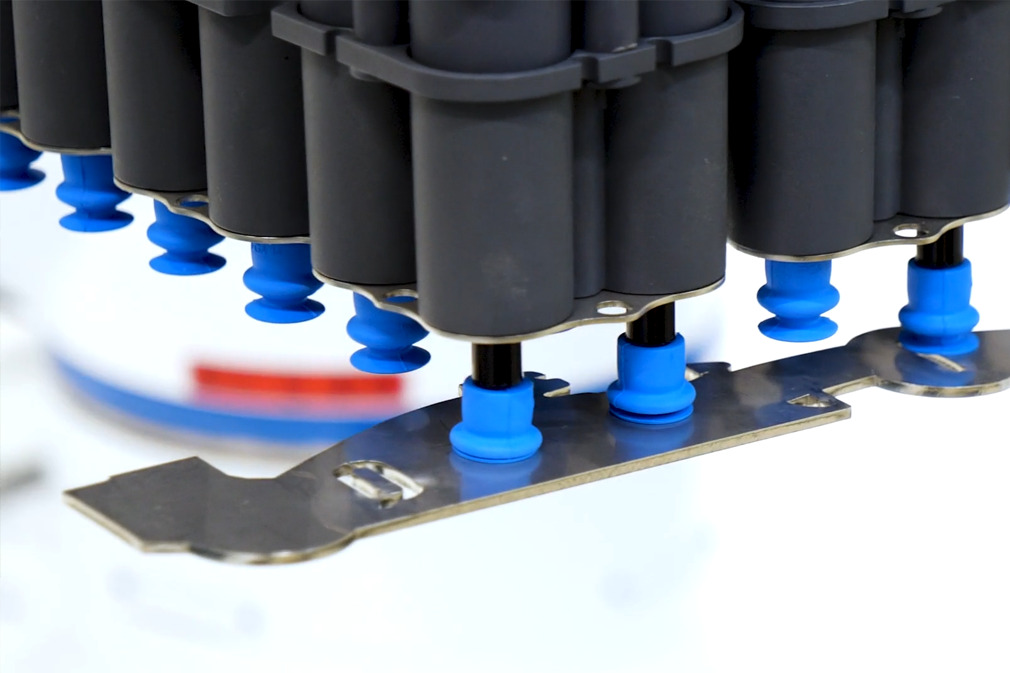

| Arrangement suction cells | 2 rows, 28 mm |

| Material type | Foam open, height 20 mm |

| Shape fittings | Pillar straight, Ø 60 |

| Weight | 16.7 (kg) |

Area Gripping Systems FMHD

Robust gripping system with integrated reservoir for external vacuum generation

The area gripping system FMHD can be integrated into systems quickly and efficiently and is equipped with a connection for external vacuum generation. Due to its integrated vacuum reservoir and robust, easy-to-maintain design, this gripper is particularly well suited to performing handling tasks under demanding environmental conditions. In addition, these grippers are ideal for operation with industrial robots and gantries due to their low weight and compact dimensions.

Ideal for highly porous and twisted workpieces

Handling of workpieces from 35 mm width, regardless of geometry, surface and position

Maximum process acceleration and reduced system costs through the use of smaller robots

Up to 70 % reduction in maintenance due to three-part profile design

Sustainable reduction in operating costs through flow optimization

Your Individual Configuration

The gripping systems FMHD are specially adapted to your applications. Contact us and receive a custom made offer.

Modular system

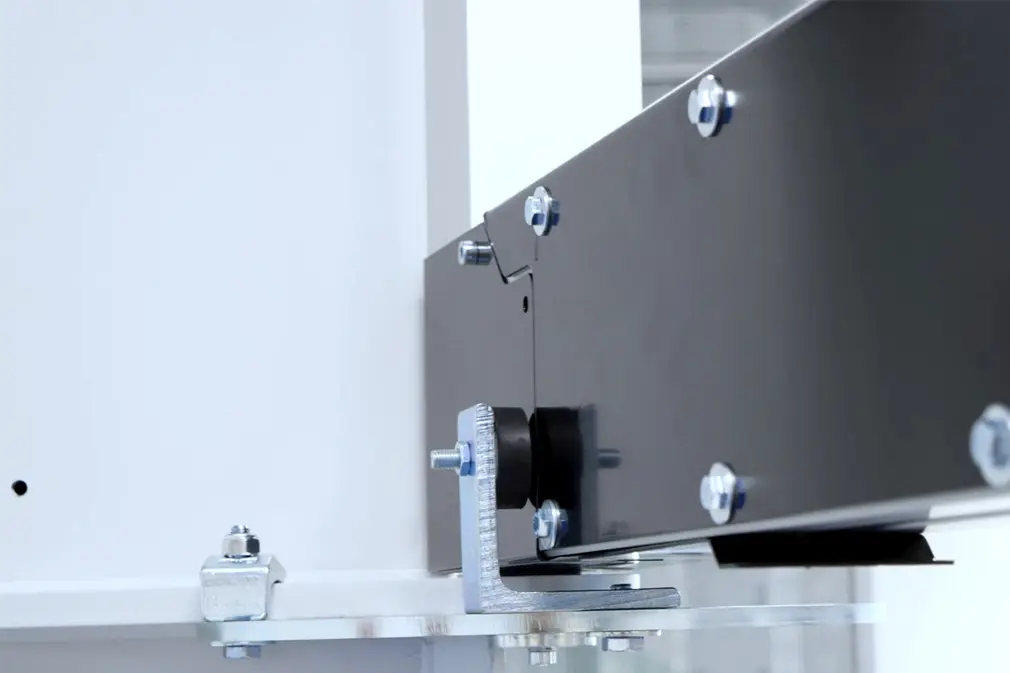

- Aluminum basic profile (1) with integrated vacuum storage for high rigidity with low dead weight

- Hose connection and separating cylinder (2); connection of external vacuum generators

- End cover (3) with control valves for separating cylinder and blow-off function

- Valve profile (4) with integrated missile valves

- Optional third row of suction holes enables handling of narrow workpieces from 35 mm width in sawmill environment

Basic variant of FMHD series

| Type | Description |

|---|---|

| FMHD | Area gripping system with external vacuum generation Width of the suction surface: 170 mm |

| FMHD-250 | Area gripping system with external vacuum generation Width of the suction surface: 250 mm |

| FMHD-3R22 | Large-area gripping system with third row of suction holes for handling workpieces with a width of 35 mm or more |

Compatibility of the basic variants

| FMHD (L < 2,506 mm) | FMHD (L = 2,506-3,500) | FMHD-250 | FMHD-3R22 | |

| FMHD | compatible | compatible | compatible | compatible |

| FMHD-250 | compatible | not compatible | not compatible | |

| FMHD-3R22 | compatible | not compatible | not compatible |

Ordering information

Product code

Similar to a part number, the product code is used to uniquely identify product configurations at Schmalz. The product code can be found on the product label or on the quotation or order. Do you have questions about your product or would you like to order a configuration again? Then please have this key ready when you contact Schmalz.

| Code | Type |

|---|---|

| FMHD | FMHD |

| Code | Type |

|---|---|

| Number | Length of gripper |

| Code | Type |

|---|---|

| 2R28 | Two rows with valve spacing 28 mm |

| 3R22 | Three rows with valve spacing 22 mm |

| Code | Type |

|---|---|

| O10O10 | Material O10O10 |

| O10O10F | Material O10O10F |

| O10O10S05 | Material O10O10S05 |

| O10O10S05F | Material O10O10S05F |

| O20 | Material O20 |

| O30 | Material O30 |

| S25 | Material S25 |

| S30 | Material S30 |

| Code | Type |

|---|---|

| ABC00001C | Individual configuration code |

Ordering information

We always produce our gripping systems FMHD to fit the customer’s application. The table below lets you determine the product key for your gripper yourself. Please send us the product key afterwards using the inquiry form.

Abbreviated gripper type designation

| Variant | Available designs |

|---|---|

| FMHD |

FMHD FMHD-250 (excess width 250 mm) |

Valve technology

| Variant | Available designs |

|---|---|

| CV1 | CV1, CV2 ball check valve |

Length (total)

| Variant | Available designs |

|---|---|

| 1,260 | From 350 mm to 3,500 mm in a 14 mm grid [in mm] |

Width

| Variant | Available designs |

|---|---|

| 250 | Standard suction plate FMHD with 170 mm (Field 12 is omitted in the order code) Width suction plate FMHD-250 with 250 mm |

Grid

| Variant | Available designs |

|---|---|

| 2R28 | 2R28 – Two rows with valve spacing 28 mm 3R22 – Three rows with valve spacing 22 mm |

Foam type

| Variant | Available designs |

|---|---|

| O20 | O10O10 – Material O10O10 O20 – Material O20 O10O10S05 – Material O10O10S05 O10O10F – Material O10O10F |

Cylinder position

| Variant | Available designs |

|---|---|

| Left; 155 mm (C155L) | Distance from left gripper edge to the center of the cylinder [in mm] |

Switch function

| Variant | Available designs |

|---|---|

| P | P – PNP switching |

Connector

| Variant | Available designs |

|---|---|

| A6L | S60 – straight, 60 mm Ø A60L – angle 60 mm Ø, left A60R – angle 60 mm Ø, right A60F – angle 60 mm Ø, front A60B – angle 60 mm Ø, rear COV – with cover plate OPE – open |

Position of connector

| Variant | Available designs |

|---|---|

| 126 | Distance from left gripper edge to the center of the support [in mm] |

Vacuum display

| Variant | Available designs |

|---|---|

| Pressure gauge (V1) | V1 – gauge VAM 40 V U V2 – vacuum switch VSi |

Compressed air connection

| Variant | Available designs |

|---|---|

| Plug-in nipple 7.2 (CA1) | CA1 – plug-in nipple 7.2 CA2 – plug-in screw union 12 |

Design Data

The design data given refer to exemplary configured large-area suction pads with the following order code:

FMHD: FMHD CV1 1050 2R28 O20 C152R P S60 126 V1 CA1

FMHD-250: FMHD CV1 1050 250 2R28 O20 C138L P S60 126 V1 CA1

FMHD-3R22: FMHD CV2 1050 3R22 O20 C152L P S60 126V1 CA1

| Attribute | FMHD | FMHD-250 | FMHD-3R22 |

|---|---|---|---|

| B | 170 | 250 | 170 |

| B14 | 191.3 | 250 | 191.3 |

| B25 | 175.5 | 175.5 | 175.5 |

| B3 | 168 | 250 | 168 |

| D | 60 | 60 | 60 |

| H | 111.6 | 111.6 | 111.6 |

| H11 | 158.6 | 163.6 | 158.6 |

| H22 | 20 | 20 | 20 |

| L (variable) | 1,050 | 1,050 | 1,050 |

| L13 (variable) | 1,057.8 | 1,057.8 | 1,057.8 |

| L2 (variable) | 126 | 126 | 126 |

| L3 (variable) | 152 | 138 | 152 |

| L4 (foam) | 1,004 | 1,004 | 1,004 |

| Y1 | 120 | 120 | 120 |

| ZA (grid) | 28 | 28 | 22 |

1 depending on the hose connection used

2 depending on the foam used

3 Use of analog pressure gauge

4 is always the largest dimension of the product

5 width of the quick change profile

Technical Data

| Type | Temperature range [°C] | Operating pressure range [bar] | Electr. connection |

|---|---|---|---|

| FMHD | 5 ... 40 | 6.0 ... 8.0 | M12, 5-Pin |

| FMHD-250 | 5 ... 40 | 6.0 ... 8.0 | M12, 4-Pin |

| FMHD-3R22 | 5 ... 40 | 6.0 ... 8.0 | M12, 5-Pin |

Exemplary technical data

| Type | Sealing material | Required volume flow [Nl/min]** | Suction force [N]* | Number of suction cells | Weight [kg] | |

|---|---|---|---|---|---|---|

| FMHD | FMHD-CV1-1050-2R28-O20 | foam, 20 mm | 315 | 2,430 | 70 | 17 |

| FMHD-CV1-1260-2R28-O20 | foam, 20 mm | 380 | 2,870 | 85 | 20 | |

| FMHD-250 | FMHD-CV1-1050x250-2R28-O20 | foam, 20 mm | 315 | 3,500 | 70 | 23 |

| FMHD-CV1-1260x250-2R28-O20 | foam, 20 mm | 380 | 4,200 | 85 | 26 | |

| FMHD-3R22 | FMHD-CV2-1050-3R22-O20 | foam, 20 mm | 315 | 1,870 | 132 | 17 |

| FMHD-CV2-1260-3R22-O20 | foam, 20 mm | 378 | 2,210 | 161 | 20 | |

*Values determined in practice when handling a typical workpiece (wooden board with structured surface, gripper fully covered by the workpiece, -0.3 bar system vacuum, without safety factor). They represent orientation values for a rough design. For detailed system design, it is always recommended to carry out suction tests with the original workpiece.

**The external vacuum generator used must provide at least the specified suction volume (at the vacuum connection piece of the FMHD-250) at a vacuum of -0.3 bar.

Documentation

The matching documentation for this product is available in this section.

| Documents | Language |

|---|---|

| Slovenian |

The documentation is also fully available in English.

| Documents | Language |

|---|---|

| English |

Videos

Discover application examples of the product in various industries - user-friendly, informative and practical.

No suitable videos found? Then take a look at our media center.

Product recommendations

Further information

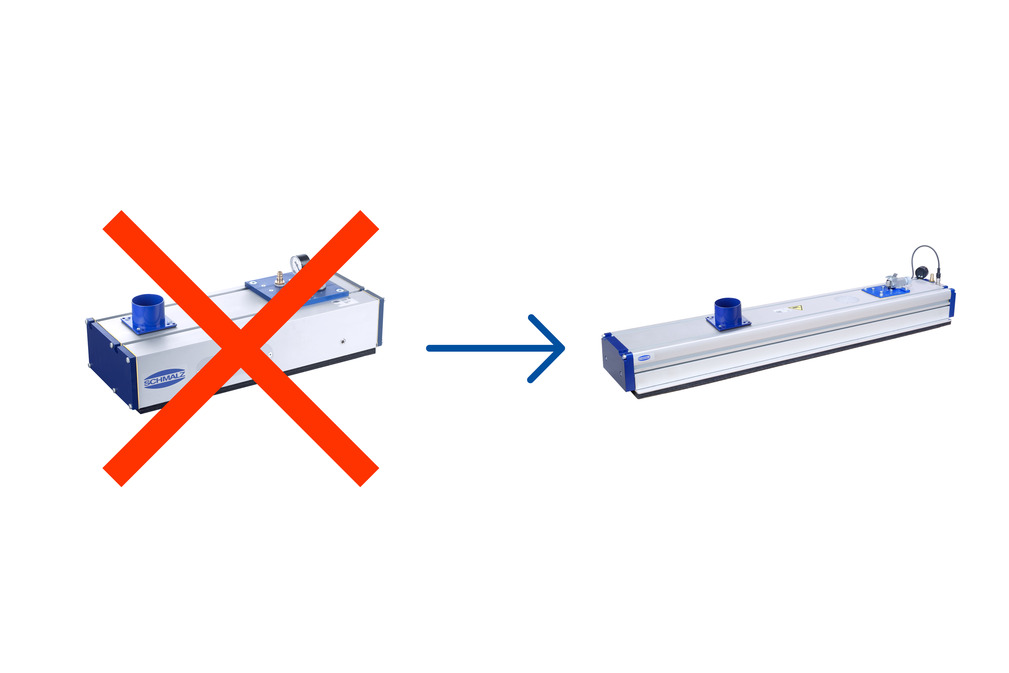

Can a gripper from the previous SBX-C series be replaced by an FMHD gripper?

An existing SBX-C gripper in customer applications can be easily replaced with an FMHD-1R gripper without any changes to the electrical interface or programming. Variants: FMHD ... 1R ... SBPL with directly attached pneumatic vacuum generator FMHD ...1R with hose connection for external vacuum generation The changeover reduces maintenance by up to 70 % and sustainably lowers operating costs. Your local contact will be pleased to provide you with further information.

What advantages does the variant with atmospheric ventilation offer compared to blow-off with compressed air and for which applications is it suitable?

After switching off the vacuum generation, a residual vacuum remains in the gripper for many workpieces. This can cause the workpieces to stick together, disrupting the process sequence.

To reliably eliminate this residual vacuum, either compressed air for blow-off or atmospheric ventilation can be used.

Atmospheric ventilation offers several advantages:

- Shorter set-down times: It enables the fastest workpiece release, especially with longer grippers. Compared to compressed air blow-off, the set-down time can be reduced by approx. 50 %.

- Cost efficiency: Virtually no compressed air is required, which reduces compressed air consumption and lowers ongoing operating costs.

Typical applications:

- Handling of sawn timber, glued wood, planed and panel goods, construction timber, pallets and crate elements

- Handling of naturally grown material with knotholes, cracks and heavily twisted and rough surfaces

- Ideal for use in sawmills, wood and furniture construction companies

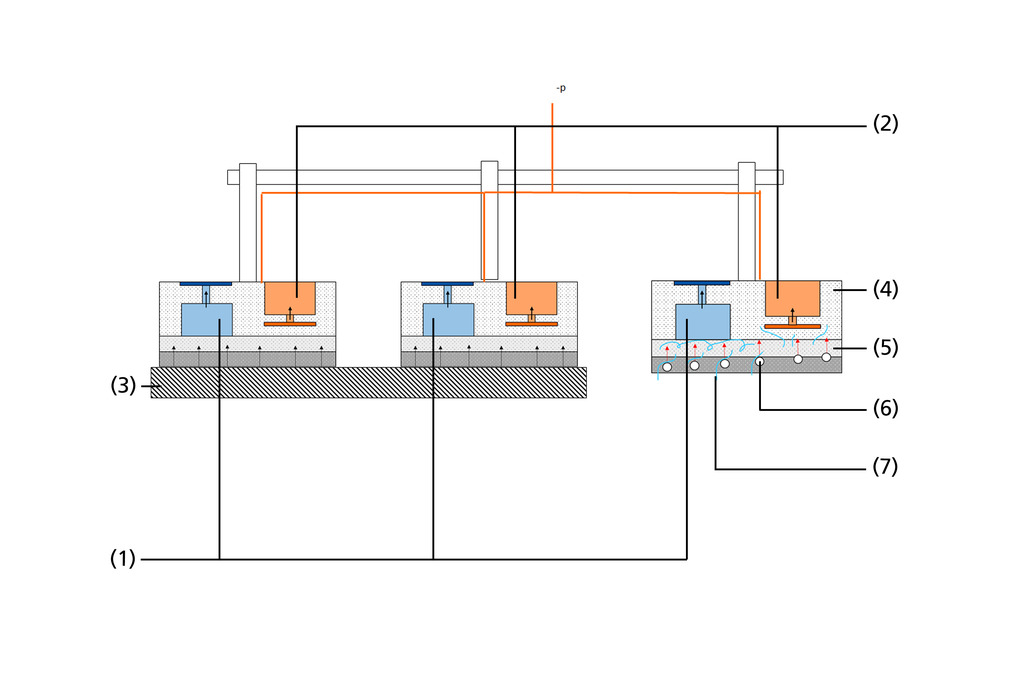

When does it make sense to use impulse valves for area grippers?

The use of impulse valves is particularly recommended when several FMHD vacuum gripper systems are combined in one suction spider.

In the event of a power failure, the cylinders for the vacuum reservoir and vent stay in their last switching position because of the impulse control. This prevents workpieces from falling off by accident and causing process disruptions or damage.

Fig.:

(1) Ventilation cylinder

(2) Separating cylinder

(3) Workpiece

(4) Storage chamber

(5) Suction chamber

(6) Balls

(7) External air