The AI-supported part recognition works extremely reliably and saves a lot of time, as the tedious manual placement of workpieces is no longer necessary.∼ Daniel Wechsel, Head of Sheet Metal Production at LISSMAC Maschinenbau GmbH

AI Sheet Metal Handling Doubles Performance

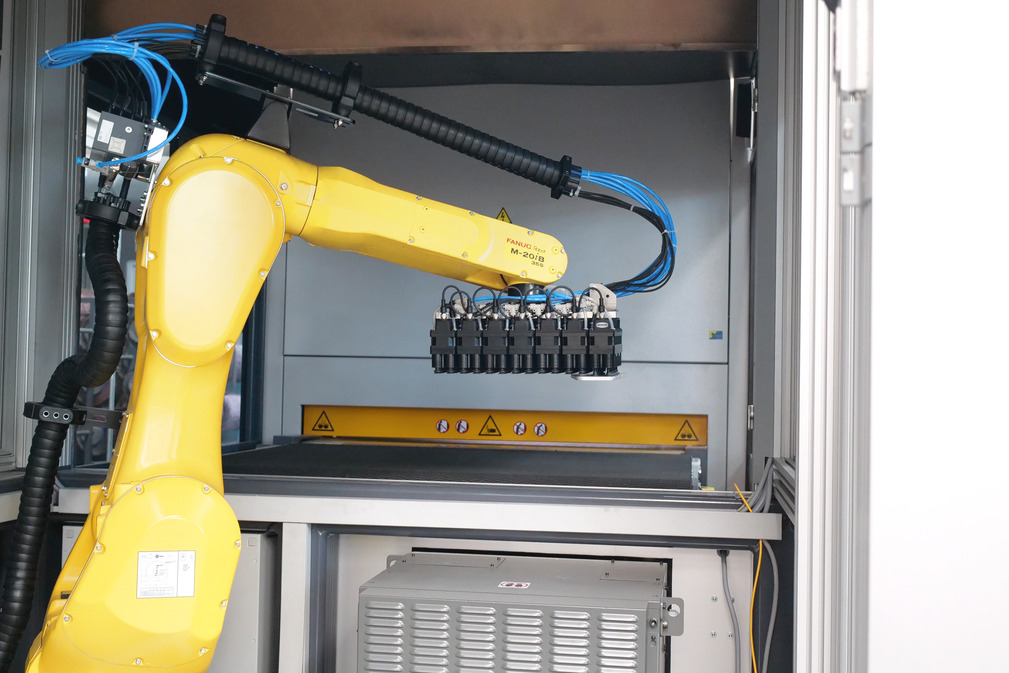

To counter the shortage of skilled workers and increase productivity, LISSMAC was looking for a solution to automate the manual loading of the deburring machines. In collaboration with Schmalz, a robot cell was created using the Solution Kit ivOS Sheet Metal. The combination of AI-supported part recognition, 3D vision sensors and the modular area gripper FMG reliably feeds workpieces into the machines. This allows LISSMAC to run several machines simultaneously, avoid bottlenecks, and significantly boost production efficiency.

Characteristics of the success story

| Industry | Mechanical engineering |

|---|---|

| Workpiece | Sheet metal |

| Product group | Solution Kits ivOS Sheet Metal |

| Type of handling | Automated handling |

With Schmalz

100

Odstotkov

more productivity

The Customer: LISSMAC Maschinenbau GmbH

LISSMAC Maschinenbau GmbH, based in Bad Wurzach (GER), has been active as an innovative machine manufacturer since 1978. The company develops and produces solutions for the construction industry, as well as for sheet metal and surface processing. A main focus is the production of deburring and grinding machines. With around 380 employees worldwide, LISSMAC is internationally successful. Over 40 percents of sales are exports, with sales and service locations in the USA and Dubai, among others. LISSMAC is known for it's high level of vertical integration, practical technology and continuous development.

The Challenge

In sheet metal production at LISSMAC, loading and unloading of the deburring machines used to be done manually, with one skilled worker required for each machine. However, a shortage of skilled workers and increasing productivity pressure were leading to bottlenecks. At the same time, the variety of workpieces (materials, geometries, surfaces) made classic automation difficult. Therefore, the company was looking for a flexible, intelligent solution that could be seamlessly integrated into the existing production process and relieve the strain on employees.

Schmalz's Solution

To overcome the challenges of sheet metal production, LISSMAC relies on the Solution Kit ivOS Sheet Metal from Schmalz. This modular automation solution combines artificial intelligence and 3D vision sensors with an intelligent matrix area gripper FMG. It recognizes different workpieces without the need for prior teaching processes and positions them precisely for further processing. The components are fed into the robot cell in sorted pallet stacks. From there, the system takes over: 3D sensors mounted on the ceiling record the geometry and position of the sheet metal, the AI interprets the data and the area gripper with individually controllable suction cups places the workpieces precisely onto the conveyor belt of the deburring machine. The system is directly connected to the machine via a specially defined interface. With a capacity of up to 1,000 workpieces per shift - and a possible maximum output of 500 parts per hour - the solution works fully automatically and is highly efficient. At the same time, it remains flexible when it comes to changing sheet geometries and surfaces. The smooth integration and intuitive operation enabled the system to be used quickly in day-to-day operations and is now running successfully in regular operation.