PCF (Product Carbon Footprint)

The product carbon footprint (PCF) describes the sum of all greenhouse gas emissions caused by a product over its entire life cycle.

This includes emissions from the extraction of raw materials, production and distribution, from the use phase to recycling, reuse or disposal. The PCF thus forms the basis for making the climate impact of products measurable and lowering it in a targeted manner.

System boundaries: cradle-to-gate and cradle-to-grave

The scopes make it clear where emissions occur. The choice of system boundary, on the other hand, determines the section of the life cycle over which a product is included in the product carbon footprint. A distinction is made between the cradle-to-gate and cradle-to-grave approaches.

Cradle-to-gate

When calculating the product carbon footprint (PCF), cradle-to-gate describes all greenhouse gas emissions from the extraction of raw materials ("cradle") to the manufacturer's factory gate ("gate"). Emissions from the use, recycling or disposal of the product are not taken into account here. This approach is primarily used when companies want to make the carbon footprint of their own production transparent without including the entire life cycle.

Cradle-to-grave

Cradle-to-grave goes one step further: in addition to the emissions from raw material extraction, production and distribution, the use phase and end of life of a product are also included. This includes reuse, recycling or disposal ("grave"). This system boundary provides a complete picture of a product's carbon footprint and is often used to map the entire life cycle analysis (LCA).

R strategies in the circular economy

An important concept for reducing the product carbon footprint are the so-called R-strategies. They stand for principles of the circular economy that can be used to reduce the CO₂ emissions of products in the long term.

"Reduce" describes the reduction of material and energy use as early as the development and production stages. "Reuse" stands for the reuse of products or components over several life cycles. "Recycle" means returning materials to the material cycle in order to make raw materials usable again. Supplementary strategies such as "repair", "refurbish" or "remanufacture" are often mentioned, which extend the service life of products and thus significantly lower both waste volumes and emissions.

Sustainable materials and EcoDesign

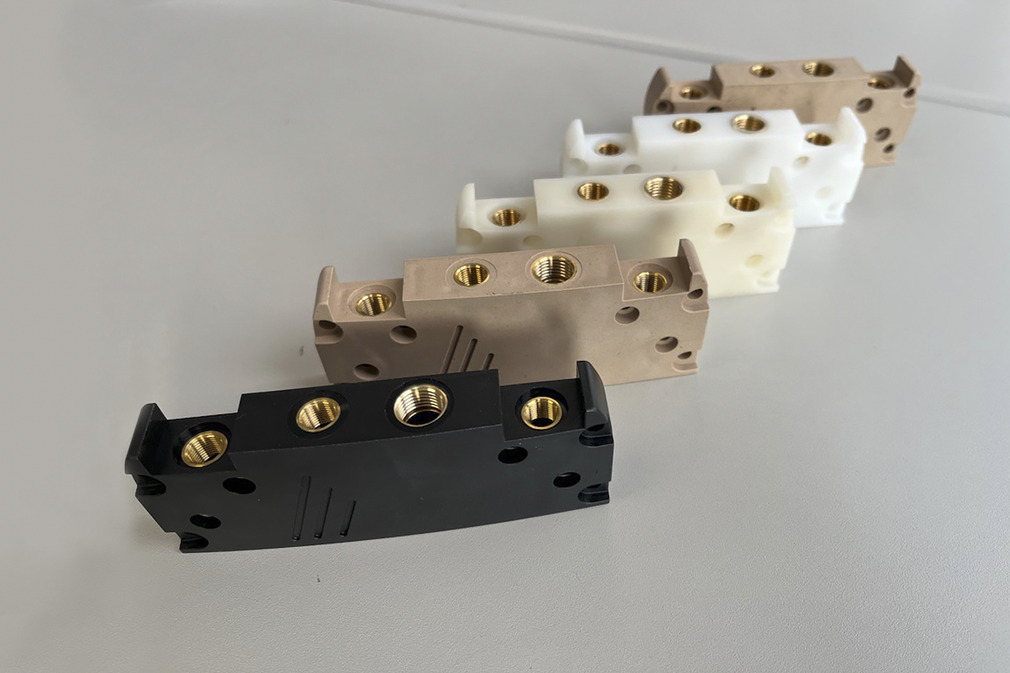

A central approach within the R strategies is the choice of sustainable materials and a well thought-out EcoDesign. The level of emissions over the entire life cycle is already determined in the early stages of product development.

The use of recycled raw materials, bio-based materials or resource-saving materials with a low carbon footprint reduces direct CO₂e emissions and contributes to resource efficiency and the conservation of natural resources.

EcoDesign allows products to be designed in such a way that they are durable, repairable and recyclable. These are all measures that significantly lower both resource consumption and greenhouse gas emissions in the value chain. In addition, the optimization of transport routes and the reduction of packaging materials play a role in avoiding additional sources of emissions.