- PHASE-OUT ITEM

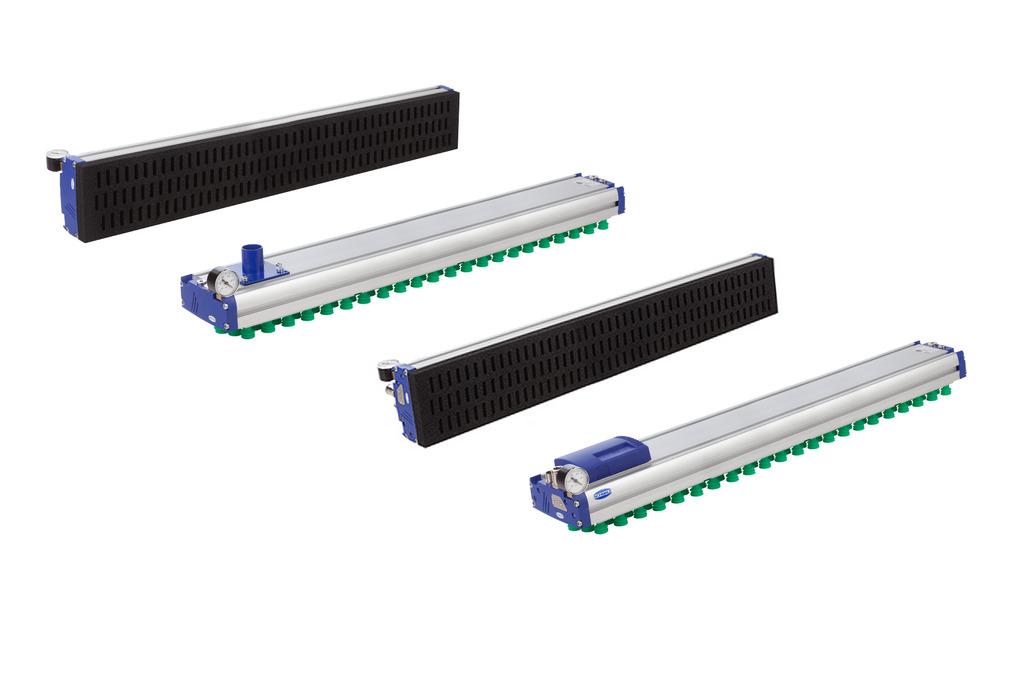

Vacuum Area Gripping System FXP / FMP

- Universal gripper for automated palletizing and depalletizing, commissioning and sorting

- Dimensions: 442 x 130 to 1,432 x 130 mm

- Sealing element: sealing foam, suction cups

Vacuum Technology for Automation

Vacuum technology from Schmalz is used as a gripper system on portals and robots. The gripping solution can be configured and designed individually with a broad range of separate vacuum components, or purchased as a ready-to-connect gripper system for a specific application.

Schmalz has developed suction cups for handling wood that more than meet the requirements of the industry. Their shape has been optimized to allow sealing on the rough, often porous surfaces of the workpieces. Ready-to-connect area gripping systems and suction spiders can be adapted to any requirement that come up in the woodworking industry. They are based on individual components to allow a custom gripper design.

Vacuum Clamping Technology

Wooden boards are processed in CNC machining centers to manufacture furniture and other products. During this process, the flat boards are clamped in the machine. Using vacuum clamping technology, suction is applied to the bottom of the workpieces to hold them securely in place. This allows the workpiece to be processed on five sides without modifying the machinery.

Schmalz offers a broad range of clamping equipment for all table types and various manufacturers. Schmalz offers machine manufacturers and outfitters complete, cross-manufacturer, individualized clamping systems for vacuum-driven machine tables.

Vacuum Lifters and Crane Systems

Because the rough wooden boards, cut pieces, workpieces, assemblies and furniture bodies can have a wide variety of shapes, weights and properties, Schmalz offers two series of vacuum lifters: vacuum tube lifters Jumbo and vacuum lifting devices VacuMaster. A large selection of different suction cups is available for both series. Specially adapted crane systems and jib cranes supplement the vacuum lifters.

Preventing Double Layers

When handling porous or permeable workpieces such as MDF or particle board, the workpieces can stick together during destacking. With large-area gripper modules from Schmalz, an integrated separating function ensures that vacuum between the boards is halted by restricting the flow of compressed air. In this way, only one workpiece is picked up and held.

Gentle Handling in Furniture Manufacturing Processes

Handling furniture places particular requirements on vacuum technology to leave few marks and prevent damage to the workpieces. Large-area gripping systems from Schmalz are equipped with suction cups or with a special sealing foam. The soft sealing foam makes it possible to handle workpieces without damaging them or leaving marks, so that they can be coated later on without surface imperfections, even after coming into contact with the gripper. The wide range of products includes suction cups made of specially-developed materials from Schmalz.

Handling Layers of small Workpieces after Processing in Nesting Processes

For layers of workpieces that were processed using nesting, extremely small individual pieces must be picked up and transported with as little additional manual work as possible. The nesting gripper SPZ-NG allows you to destack cut pallet layers in just one handling procedure. Different vacuum circuits make it possible to split the gripper into individual segments. Individual vacuum circuits can be switched on or off as needed, for example in order to avoid picking up certain workpieces during gripping.

Handling Workpieces with Gaps

The large-area gripping system FXP/FMP is used for handling workpieces with large gaps, such as doors with cut-outs for windows. The universal gripper is equipped with a special sealing foam and valve components. This makes it possible to handle doors with narrow frames and large openings.

Working in dusty Environments

When handling lumber, sheet materials, laminated beams, construction timber, CLT sheets, pallets or simply natural materials, knot holes, cracks and damaged material with rough surfaces can make it difficult to use standard solutions. The patented large-area gripping system FMHD was especially designed for these conditions. The large-area gripping system FMHD can also be used effortlessly in environments with large dirt particles, in wet environments, cold environments and when working with resin.

Handling Wood Veneers

The thin wooden layers are extremely delicate and can be cracked easily during transport. Schmalz large-area gripping systems ensure particularly gentle handling of instable workpieces, which allows you to destack and transport veneers without cracking or damaging them.

Increasing the flexibility of CNC machining centers

Clamping with vacuum in CNC machining

Production and further processing of wood-based materials

Handling of prefabricated wood parts

Discover application examples of the product in various industries - user-friendly, informative and practical.

No suitable videos found? Then take a look at our media center.