Special Grippers

Special grippers are used in applications in which regular suction cups cannot be used. Special grippers are used to handle wafers, films, paper, fragile workpieces or textile fiber composites. They serve as a connection element between the workpiece and the handling system just like the suction cup.

Schmalz separates special grippers into the following series:

- Floating suction cups

- Magnetic grippers

- Needle grippers

- Wafer grippers

- Composite grippers

- Thin glass gripper

Our selection aid includes information that should be observed when selecting the right special gripper.

Floating Suction Cups

Floating suction cups work pneumatically according to the Bernoulli principle and are used to grip very sensitive workpieces. Read about the advantages of floating suction cups.

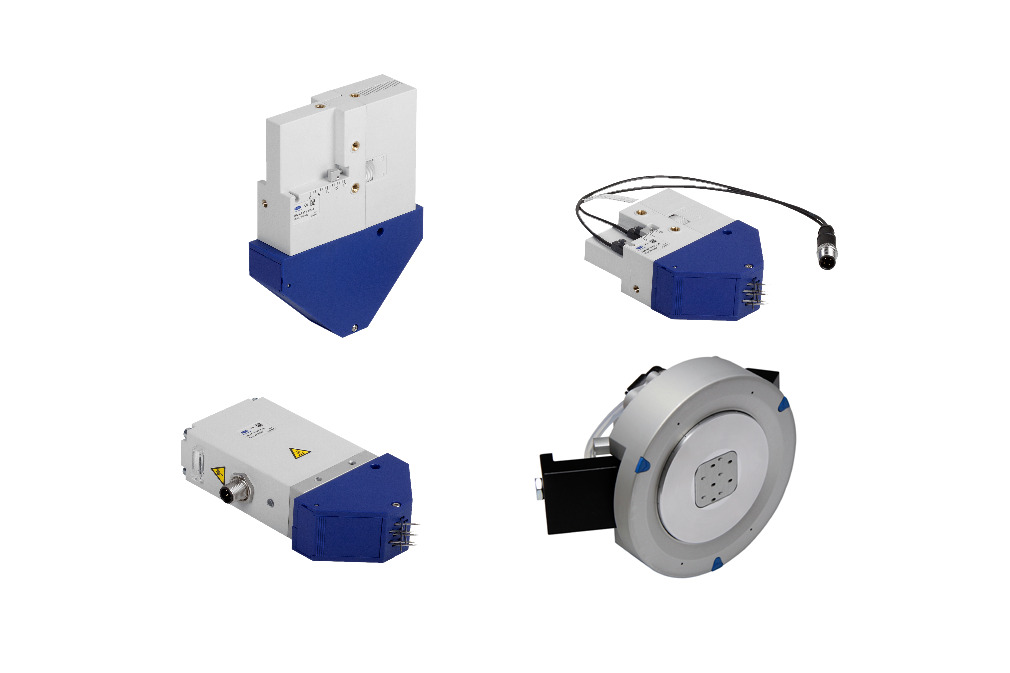

Magnetic Grippers

Magnetic grippers provide safe gripping of ferromagnetic workpieces by using the magnetic field of an integrated permanent magnet.

Needle Grippers

Needle grippers pierce the workpiece being handled in order to grip it securely. Use Schmalz needle grippers to handle difficult-to-hold materials.

Wafer Grippers

Wafer grippers are ideally suited for the handling of sensitive parts, especially photovoltaic components such as wafers and cells.

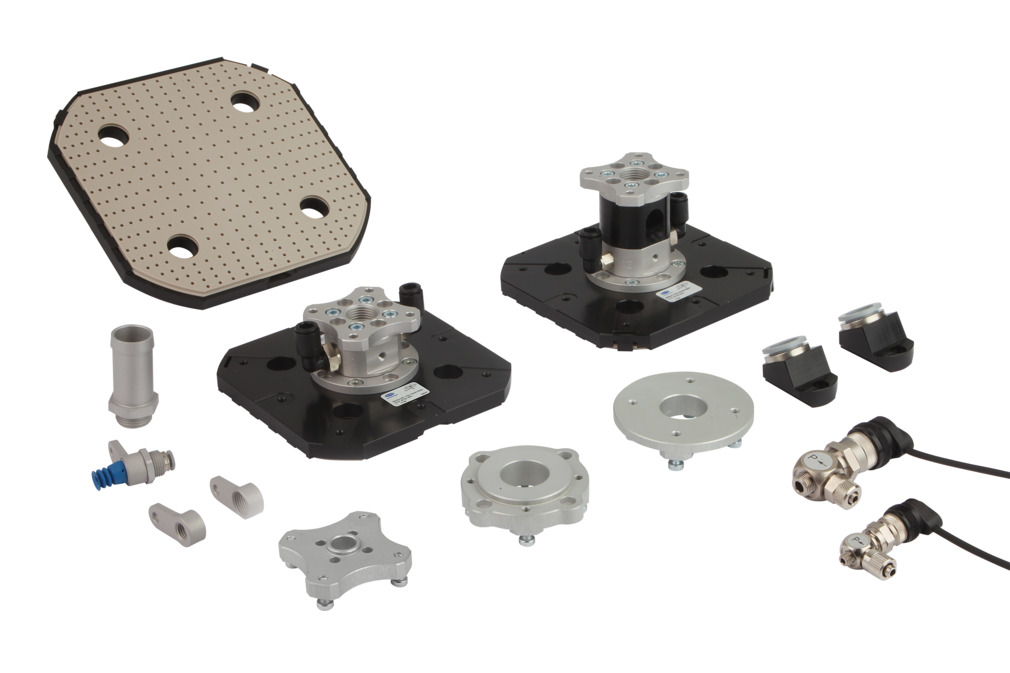

Composite Grippers

Due to their high volume flow and the moderate vacuum level, composite grippers are ideally suited for handling fragile components.

Thin Glass Gripper

The thin glass gripper is a special gripper for the extremely dynamic and gentle handling of sensitive workpieces in automated or semi-automated processes.

Selection by Workpiece

Use the selection aid to help you select the right special gripper. The table contains information about the workpiece and outlines the product characteristics of the gripper.