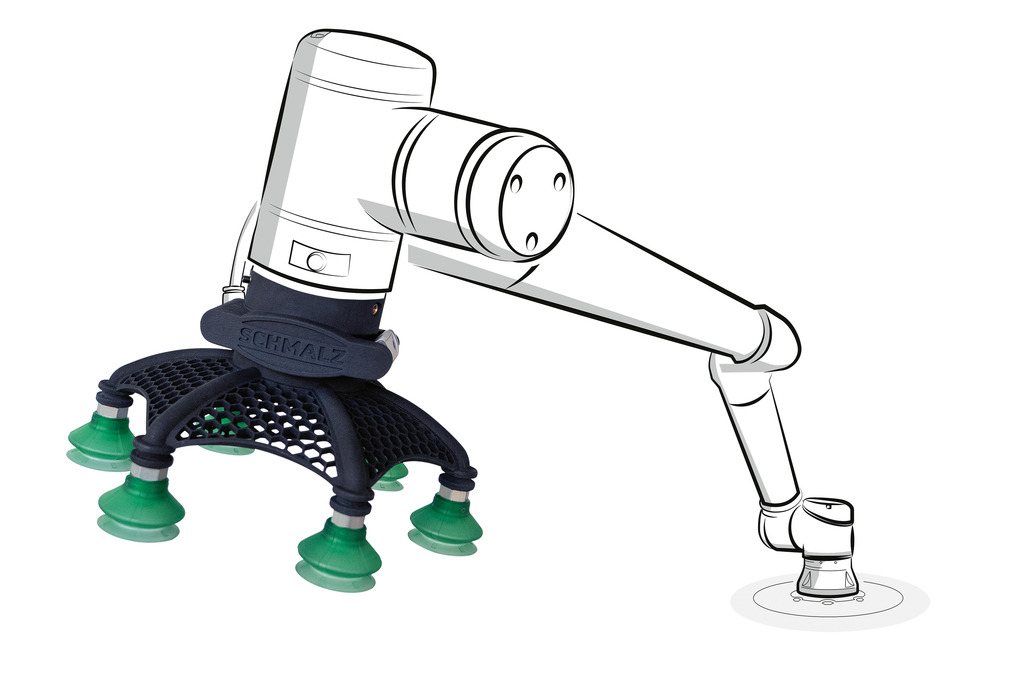

Vakuová technologie pro robotiku

- Individuální a flexibilní vakuové uchopovací systémy pro použití v lehkých robotech a kobotech

- Sady připravené k připojení pro robotickou manipulaci a vybírání zásobníků

Plug-and-work defines a concept in automation that makes it possible to integrate machines and robots quickly and easily into existing production systems without the need for extensive programming or lengthy set-up times. Devices or machines are ready for operation immediately after connection.

In a plug-and-work system, the required hardware is simply connected and associated software plug-ins allow for quick setup and programming.

Network technology is used to ensure efficient communication between the systems, enabling information to be exchanged in real time. This leads to fast self-configuration of the machines and reduces the need for manual start up, making the implementation and adaptation of automation solutions much easier.

Plug-and-work systems are primarily used in manufacturing, logistics, the electronics industry and in automotive and food production. In various industries, they enable machines to perform tasks such as sorting, packaging, picking and the loading and unloading of containers, cardboard boxes and pallets in an efficient manner.

These adaptive systems adapt flexibly to different requirements and thus optimize production processes. Information is exchanged between machines, IT systems and databases via standardized communication protocols, enabling seamless integration into existing systems.

This uncomplicated implementation of automated processes, supported by precise engineering, ensures rapid implementation without interrupting ongoing operations and increases efficiency.

Plug and work systems are crucial for Industry 4.0, as they enable the rapid integration and configuration of machines. These systems offer high flexibility and adaptability, enabling a rapid response to changing production requirements.

By using IoT technologies and cyber-physical production systems, they improve the exchange of information and optimize production processes in real time. Standardized components and seamless integration into IT systems and control systems make production lines more efficient and flexible.

Plug and work systems lower costs, shorten working times and increase productivity through improved data management and communication between machines. They are a key to automation and enable companies to adapt quickly to market requirements.

Find answers to questions about automated processes with cobots and vacuum grippers, and how to select your vacuum gripper and generator.

Find more about communication interfaces IO-Link.

Find more about communication NFC technologie.

Detailed information about Ethernet