Clean rooms and hygienic areas

Two worlds, one claim: absolute purity.

In sensitive production environments, cleanliness and hygiene are not an option, but a matter of survival. Even the smallest mistake – whether due to contamination, unclean handling or inefficient processes – can have enormous consequences: Loss of quality, damage to consumer health, loss of production, damage to image or even legal consequences.

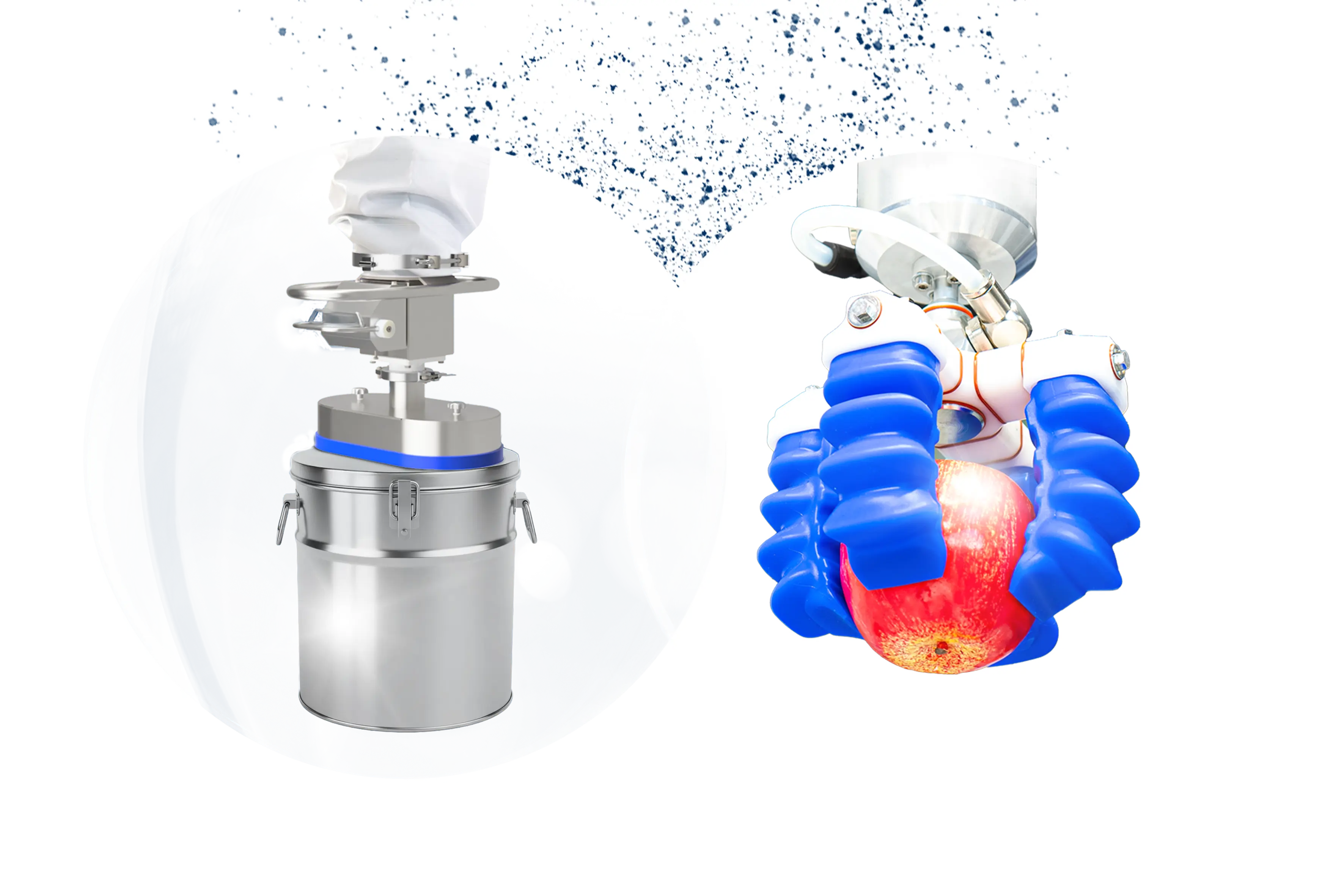

In order to meet these high requirements, different concepts are used, each pursuing specific protection goals. This is precisely where two worlds meet, which at first glance appear to be different and yet pursue a common goal: cleanrooms and hygienic areas. While cleanrooms are primarily focused on particle and germ freedom, hygienic areas concentrate on protection against microbiological contamination and infections. Different approaches – one common claim: uncompromising protection against contamination and process safety.

of contamination in a cleanroom is caused by people, especially by skin flakes or clothing.

micrometers is the particle size that is filtered out by cleanrooms. By comparison, a human hair has a diameter of around 70 micrometers.

particles per minute can be released from textiles. This is why special cleanroom clothing is essential.

of infections can be prevented in hygienic areas through consistent cleaning and disinfection.

Purity in cleanrooms and hygienic areas is more than a standard to us. It is our commitment to quality and process reliability.∼ Matthias Müller, Head of Sales, Vacuum Automation

Handling in hygienic areas and cleanrooms requires strict measures to prevent contamination and comply with cleanliness standards. This includes the use of suitable personal protective equipment (PPE) such as protective suits, gloves as well as mouth and nose protection, regular hygiene training and the correct use of auxiliary and operating equipment such as lifting devices.

Quick movements and frequent surface contact must be kept to a minimum, and tools and materials must be sterile and disinfected. Cleaning, decontamination and maintenance processes, including the maintenance of ventilation systems, ensure that cleanliness is permanently safe. These measures ensure product quality and process reliability.

This is precisely where Schmalz comes in with its specially developed vacuum automation and handling solutions for handling in cleanrooms and hygienic areas. Our products and systems are an integral part of modern cleanroom technology and make a decisive contribution to avoiding contamination and reliably complying with cleanliness standards.

From class limits and test procedures to detailed specialist knowledge. Discover all essential information about cleanroom technology here.

Our Schmalz solutions can be used in a wide variety of applications. Discover specific solutions for your industry and application.

Clean processes guaranteed: Discover our success stories for hygienic handling.

Discover how Schmalz shapes innovations for the future with cutting-edge technologies and deep know-how.

Johannes-Schmalz-Str.1

72293 Glatten

Germany