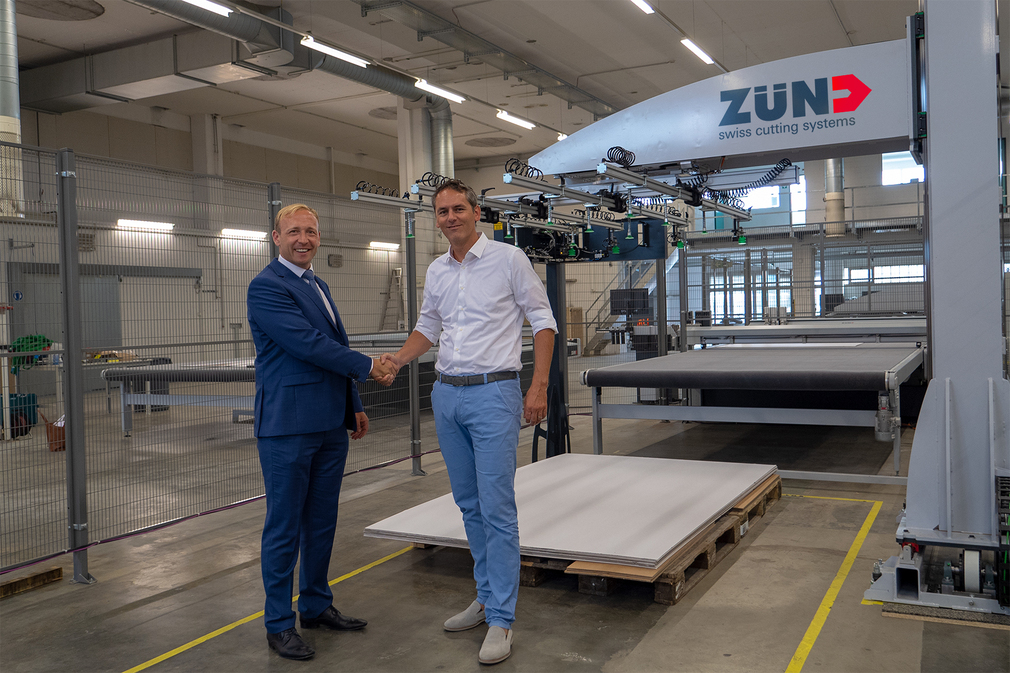

Schmalz immediately understood the requirements and translated them into a perfectly functioning system.∼ Oliver Zünd, Managing Director Zünd Systemtechnik AG

Zünd Cutter Automated With Schmalz Gripping System

Trade show and furniture builders, advertising technicians and packaging experts use cutter systems to cut materials precisely to size. Zünd Systemtechnik AG is a competent partner for this. For the latest development, a cutting table with an automatic feed and removal system, the Swiss machine manufacturer brought Schmalz on board as an experienced expert for the design of the vacuum system.

Characteristics of the success story

| Industry | Mechanical engineering |

|---|---|

| Workpiece | various |

| Product group | Vacuum Gripping Systems |

| Type of handling | Automated handling |

With Schmalz

800

doors

per week

The Customer: Zünd Systemtechnik AG

Zünd Systemtechnik AG was founded in 1984 by Karl Zünd. The company had previously sold flatbed plotters. In 1988, the company became a public limited company and began developing its own cutting machines. Today, Zünd Systemtechnik AG is a globally active Swiss family business with over 300 employees and is one of the leading manufacturers of modular and digital cutting systems. In addition to its own sales and service organizations in the USA, China, Thailand, India, Germany, the United Kingdom, the Netherlands and Italy, the company works with independent long-standing sales partners worldwide. Zünd Systemtehnik AG's customers come from commercial service and industrial companies in the graphics, packaging, clothing, leather, textiles and composites sectors.

The Challenge

Zünd required a vacuum solution from Schmalz to improve the efficiency and automation of the new cutting tables. These cutting tables should enable higher productivity and longer operating times so that customers can work more economically and efficiently. Vacuum technology from Schmalz is used as an automated supply to the cutting table to pick up materials safely and precisely from the stack and transport them to the cutting table.

Schmalz's Solution

The new BSH150 board handling system enables a stacking height of 1.50 meters and thus extends operating times. In addition to the cutting table, the system consists of an automatic supply with vacuum gripper spider and an automatic removal station. An important requirement for the system, in addition to a high output, was the ability to process orders unmanned overnight. The Schmalz suction spider takes different layers of material from the stack on a pallet and orients them. A scanner then reads the QR code with the order ID and designs the material on the cutting table. The suction cups used for the separation and stacking process are able to safely pick up different materials: The SPB2 suction cups with flexible, adaptable sealing lip adapt perfectly to different surfaces and seal well. Supplementary round flat suction cups are installed, which can grip the workpiece particularly quickly and accurately due to their flat shape and small volume. In order to achieve the required short cycle times, the vacuum is generated directly on the suction cup using the ecoPump SEP ejector module with silencer. The efficient vacuum generator enables high flow rates, which also ensures fast processes. Schmalz also supplied the spring plungers for an optimally functioning gripping system - they compensate for height differences, protect the surface and ensure a soft touchdown - as well as the necessary connection elements including aluminum profiles.

One suction cup for all materials – the simplicity of the solution is convincing.

The vacuum of the suction spider generates an ecoPump SEP and ensures short cycle times

Successful collaboration: Christian Landis (Schmalz) and Oliver Zünd in front of the BHS 150.