| Number of needles | 6 |

| Needle diameter | 1.5 (mm) |

| Additional function | Variable stroke, high force |

| Needle stroke Z(NA) | 25 (mm) |

| Pressure range (operating pressure) [bar] | 3.0 ... 7.0 bar |

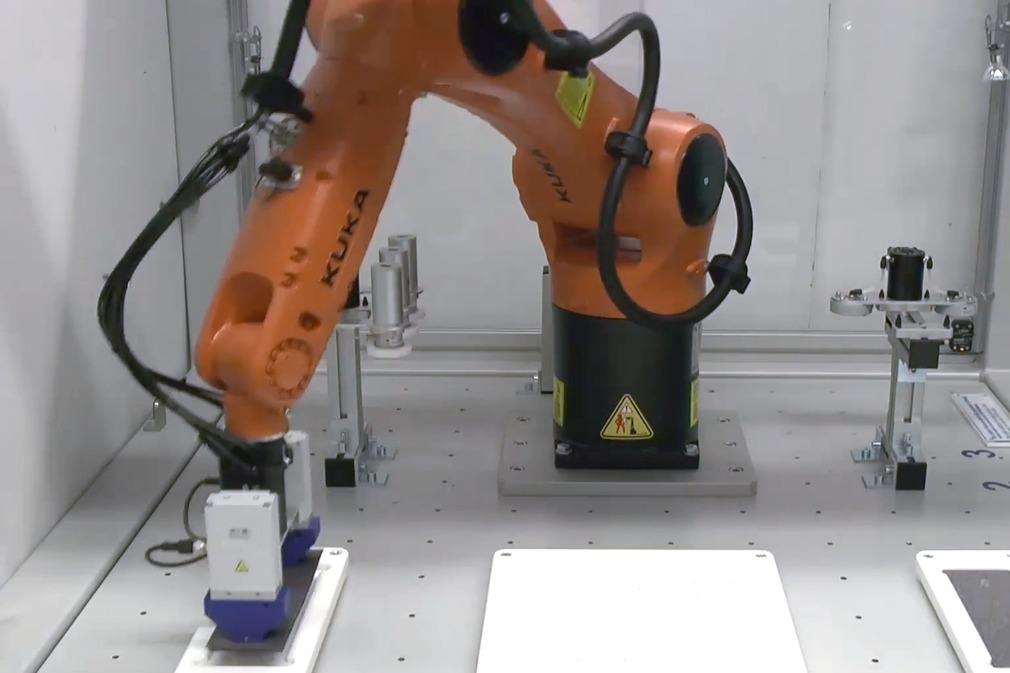

Gripping Technology in use during Hot Pressing of SMC

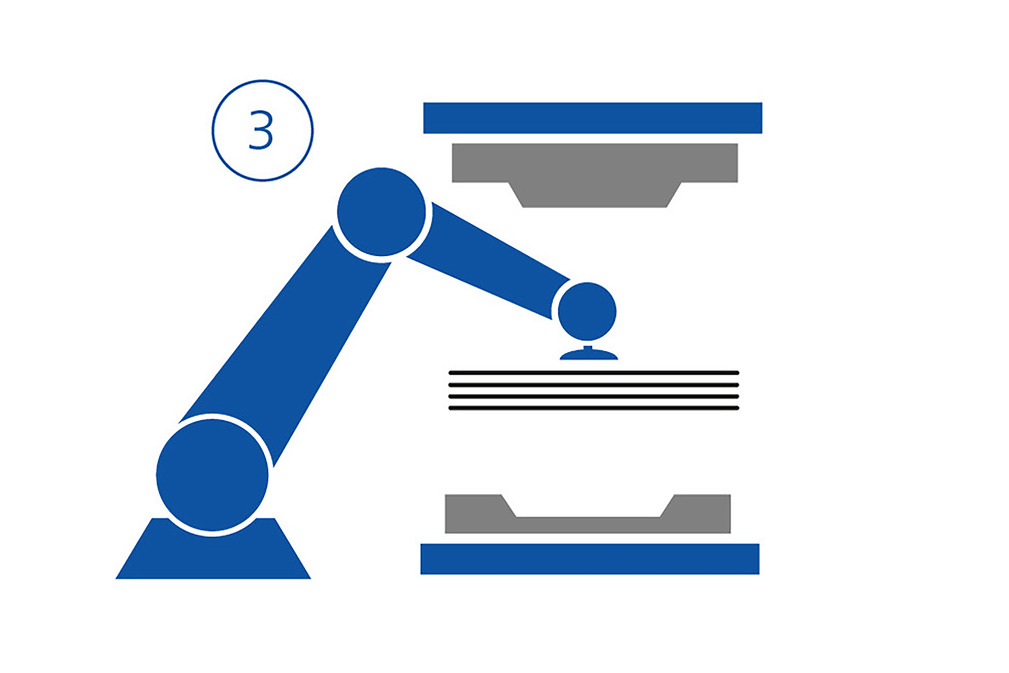

When processing SMC (sheet molding compound), the material comes on a roll and is cut into the desired pieces on a cutting unit. The long fibers with a length of maximum 50 mm, are embedded into the duroplastic matrix and are randomly oriented. A gripper picks up the tough, pasty and tacky cut pieces, places them layer by layer on a preparation table and a weighing unit measures when the desired amount of material is reached (2). A gripper, which is usually a special needle gripper with a high penetration force, picks up the stack of individual layers and positions it in the press (3).

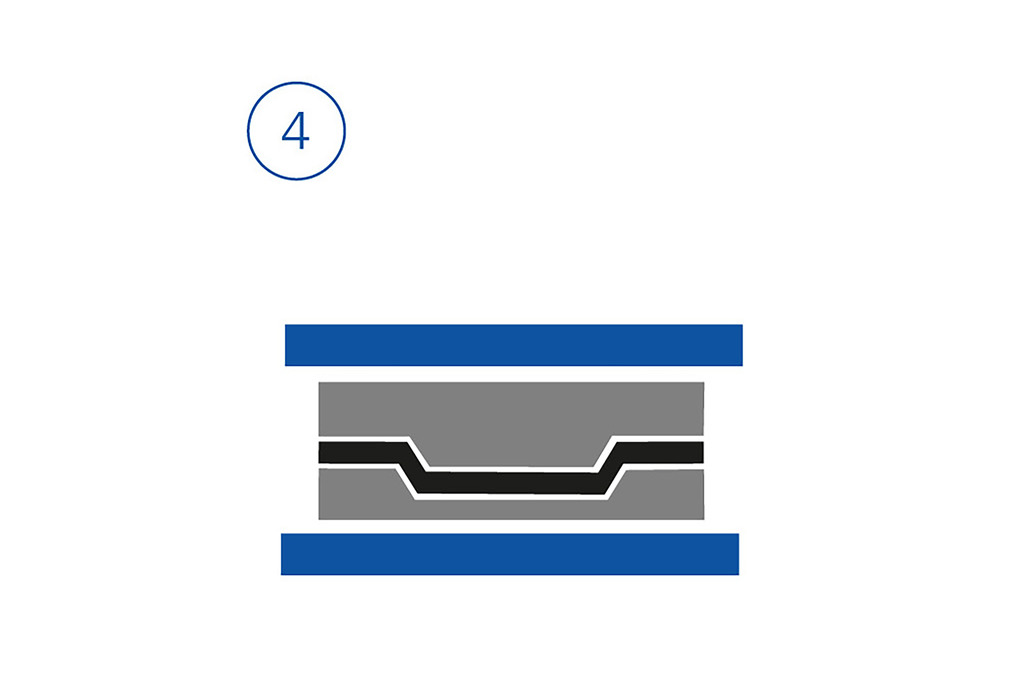

The SMC material already contains all of the components (resin and reinforcing fibers) required for production. Under high temperatures, the semi-finished product is plastified and molded into the desired shape (4).

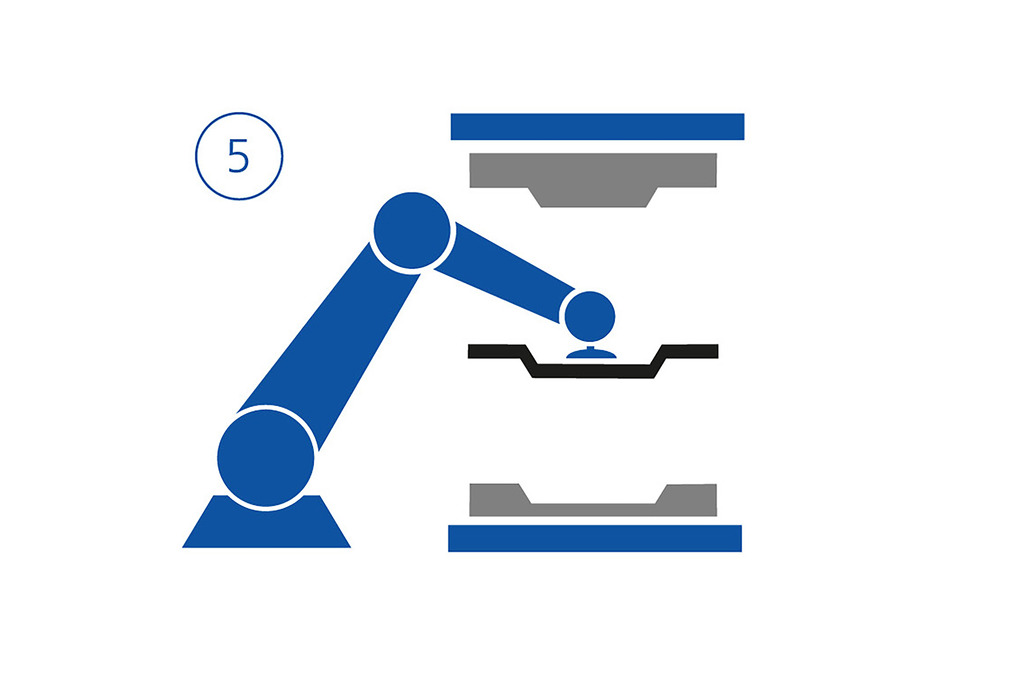

The finished part is removed with vacuum suction cups that are ideally "non-marking" and resistant to heat like the ones made of the material type HT1 (5).

요구 사항

Requirements for Gripping Technology

Tackiness of the workpiece

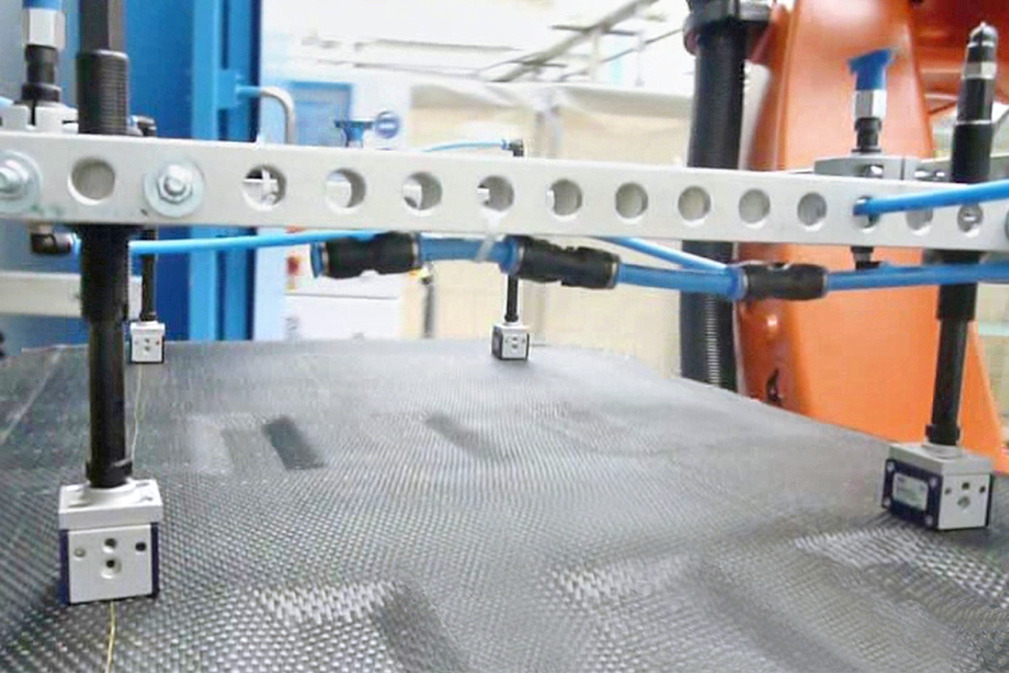

A feature of SMC materials is their tacky surface due to their composition of reactive resins and reinforcing fibers. It is a challenge for the gripper to ensure that the cut piece does not remain stuck on the gripper during the handling process.

Resistance of the material

The rubbery, pasty material can only be handled with difficulty using conventional grippers. Due to its high level of resistance, the material is very difficult to penetrate and requires a high insertion force.