"Schmalz's products are technically advanced, reliable, and the consultation service is excellent."∼ Michael Gierten, Automation and Process Technology

PRÜM-Türenwerk: Less Energy, Same Power With FA-X

PRÜM-Türenwerk wants to lower energy costs in order to achieve its sustainability goals. By using the latest generation of vacuum grippers, the company is reducing its compressed air consumption by 33 percent.

Characteristics of the success story

| Industry | Construction supplier |

|---|---|

| Workpiece | Interior doors |

| Product group | Vacuum Gripping Systems |

| Type of handling | Automated handling |

With Schmalz

33

percent

lower energy consumption

20

percent

more gripping cycles

The Customer: PRÜM-Türenwerk GmbH

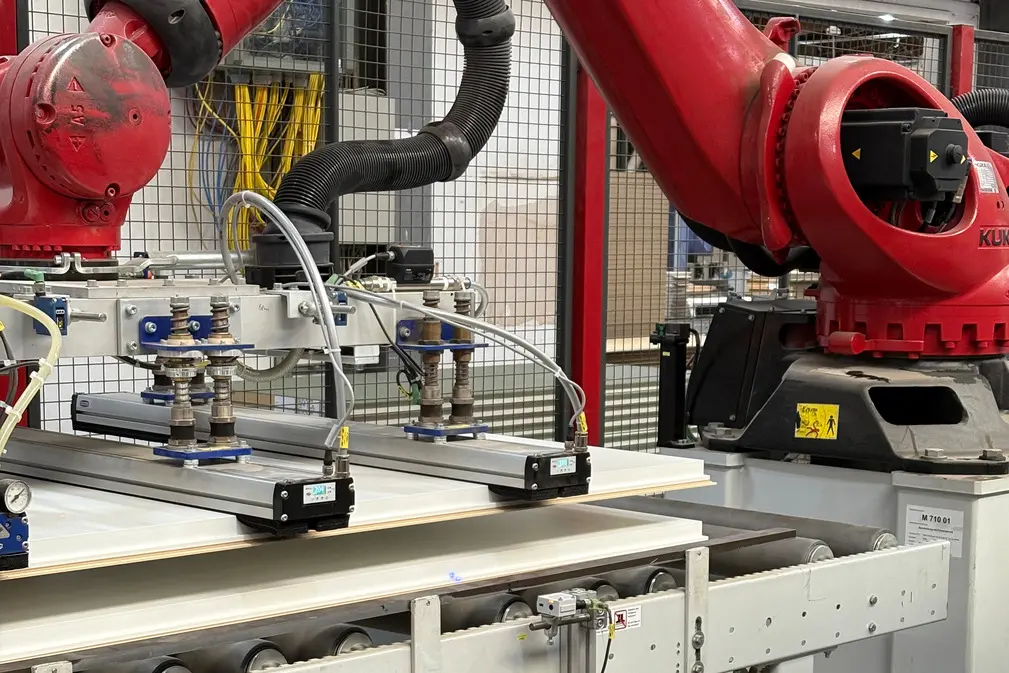

PRÜM-Türenwerk GmbH is one of Germany's leading manufacturers of high-quality interior doors and frames. Employing around 800 people, the company produces millions of door leaves every year and supplies customers throughout Europe. PRÜM stands for innovation, quality and custom-made solutions for private and commercial construction projects. Thanks to its highly automated production processes, PRÜM can manufacture door leaves in a wide range of dimensions and versions. These range from compact formats to large-format door leaves with dimensions of up to 2,500 x 1,500 millimeters and a weight of up to 150 kilograms. This diversity places special requirements on handling technology and automation solutions.

The Challenge

For many years, vacuum surface gripping systems from Schmalz have been used in production at PRÜM for the automated handling of door leaves weighing up to 150 kilograms. Although this solution worked reliably, it resulted in relatively high compressed air consumption by today's standards. As the company had set itself ambitious sustainability targets, this presented an economic and ecological challenge. The aim was to significantly reduce energy costs and consumption by 2028. PRÜM-Türenwerk GmbH therefore needed a solution that offered maximum energy efficiency without compromising on reliability or functionality.

Schmalz's Solution

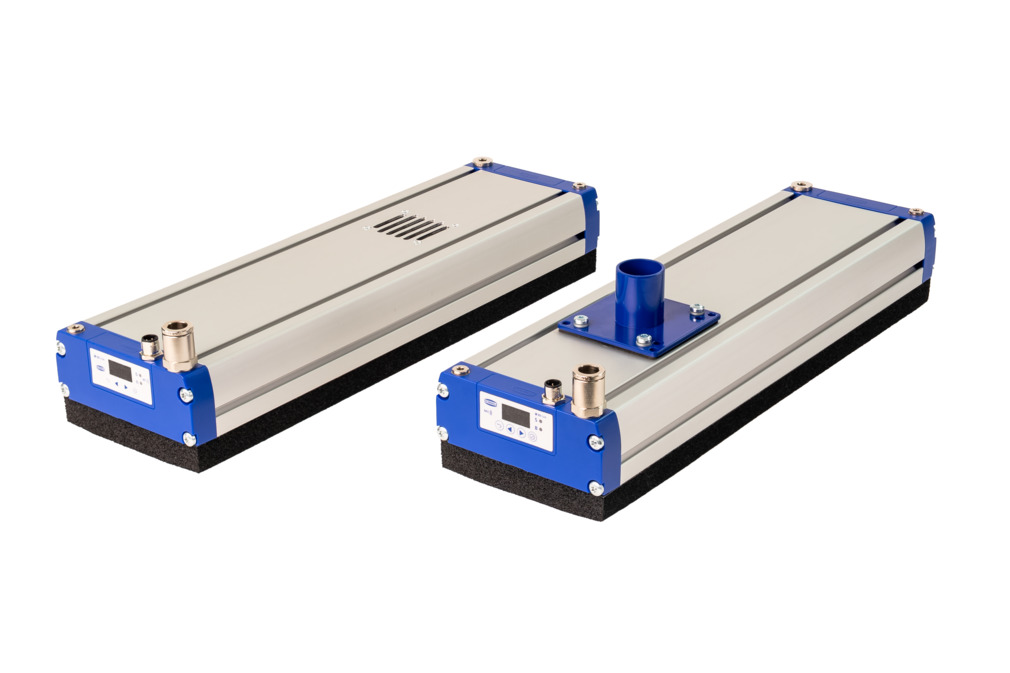

Thanks to its long-standing cooperation with Schmalz, PRÜM-Türenwerk GmbH is able to use the new, energy-efficient vacuum area gripper FA-Xi in production immediately. The Schmalz contact person understands PRÜM's requirements, materials and processes inside out and presents a custom-made solution. The new FA-Xi delivers impressive results. Compressed air consumption is reduced by 33 percent, while cycle time is cut from 13 to 10 seconds. A key advantage is the intelligent control system, which automatically switches the required nozzle strands on or off depending on the workpiece quality and occupancy level. Depending on the application, this can save up to 80 percent of the compressed air required compared to similar products - a significant factor in reducing operating costs and achieving the 2028 sustainability targets. The universal gripper reliably handles workpieces made of various materials, such as wood, plastics and other surfaces, regardless of their size or geometry. Thanks to its compact design and low weight, the gripper can be integrated directly onto the robot to save space. Simple maintenance with quick-change adhesive film also reduces downtimes to a minimum. PRÜM can therefor support its 2028 sustainability targets without any operational losses.