We wanted an all-in-one solution, and the VCBL-HD combines the goods from both vacuum block worlds.∼ Michael Ziegler, Managing Director Ziegler Holz- und Kunststofftechnik GmbH

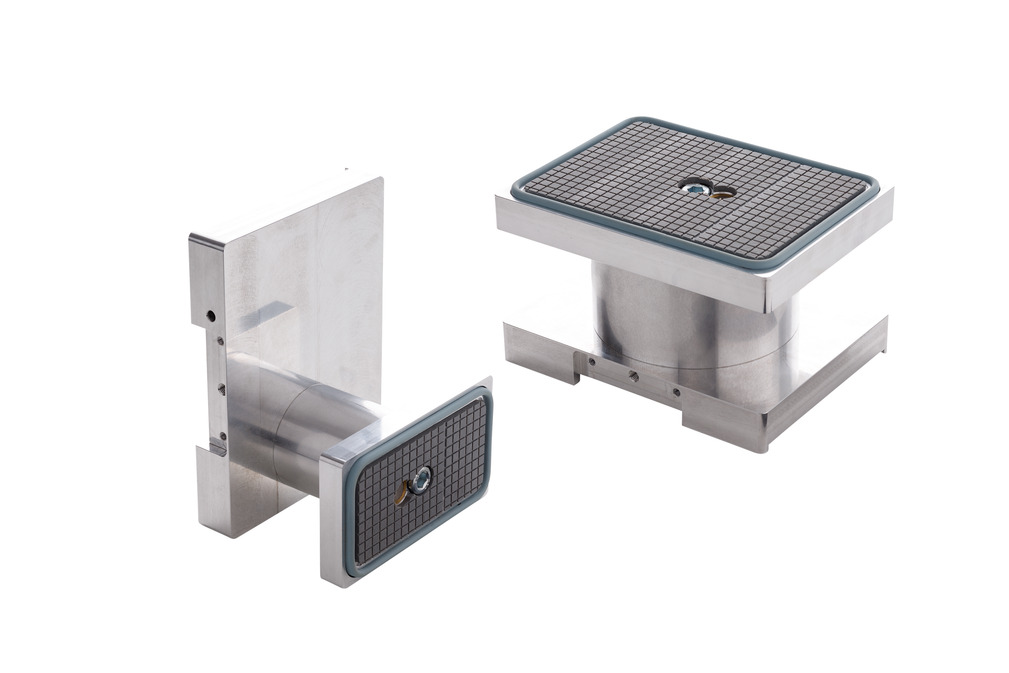

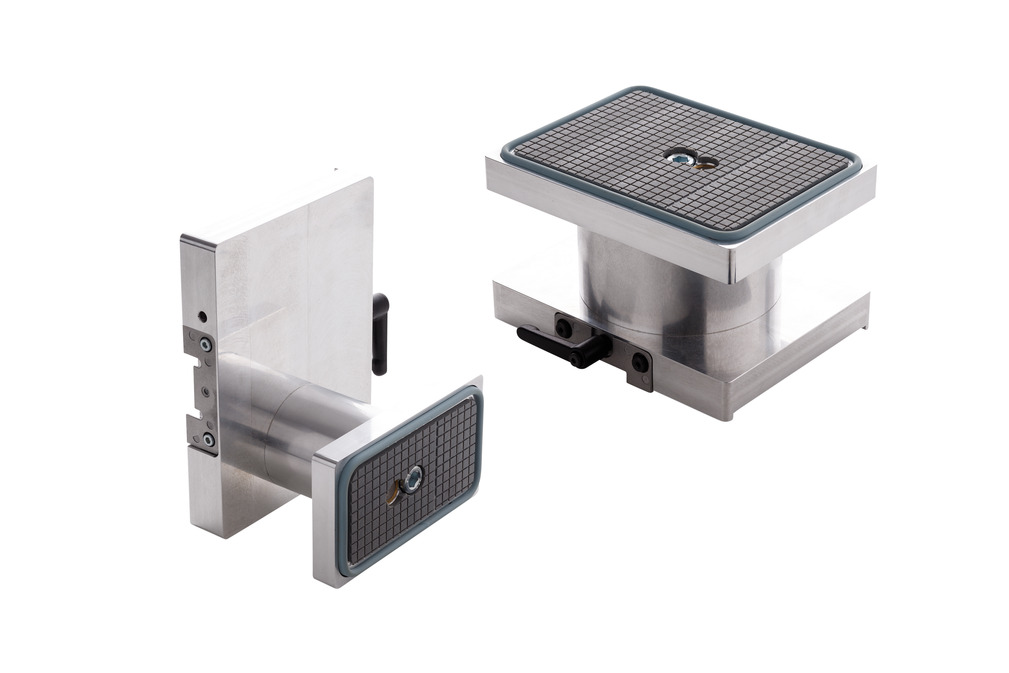

VCBL-HD: Vacuum Block for all Workpiece Sizes

Ziegler Holz- und Kunststofftechnik was looking for a versatile clamping solution for various workpieces, from pressboard and OSB sheets to sensitive surfaces, molded wood and solid wood parts. Schmalz involved the furniture manufacturer in the final development of the new VCBL-HD vacuum block.

Rysy úspěšného příběhu

| Průmysl | Wood |

|---|---|

| Obrobek | Pressboard, OSB sheets, molded wood, solid wood |

| Skupina výrobků | Vacuum Clamping Systems |

| Typ manipulace | Clamping |

Se společností Schmalz

52

Procento

more holding force

Zákazník: Ziegler Holz- und Kunststofftechnik GmbH

Ziegler Holz- und Kunststofftechnik GmbH specializes in the manufacture of complex three-dimensional moulded parts. The company also supplies furniture manufacturers, trade show and store fitters, caravan manufacturers and the packaging industry with classic solid wood products. With over 3,000 square meters of production space, the company employs 16 employees who manufacture sophisticated wooden parts of all kinds, whether as individual pieces or in large series.

Výzva

Ziegler currently uses two types of Schmalz vacuum blocks: The VCBL-A-K2 aluminum vacuum blocks are used to fix solid wood panels to the CNC table. The main advantage of these VCBL-A vacuum blocks is their aluminum body, which creates a low-vibration connection between the machine table and the workpiece. However, the special friction pad of these vacuum blocks requires subsequent processing of the workpieces as it can roughen the surfaces. Ziegler uses the VCBL-K2 vacuum block for the manufacture of standard furniture parts. Although this is gentle on the surface thanks to its elastomer suction plate, its design was not stable enough for processing solid wood.

Řešení od společnosti Schmalz

The solution from Schmalz is called VCBL-HD. The vacuum block offers numerous advantages and has been perfected in cooperation with Ziegler as a development partner. This vacuum block is characterized by a reinforcing design, reduced return force of the seals and a slightly roughened friction pad. In addition, it enables efficient processing of materials such as Corian and HPL, which was previously difficult to achieve with the standard K2 suction cup due to damage to the workpiece surfaces. The new vacuum blocks have proven themselves in use at Ziegler, as they offer more flexibility, reduce set-up processes and increase throughput speed when processing solid wood. They also make it possible to clamp thin-walled and sensitive workpieces without reworking. The rotatable suction plate allows the carpenter to adapt the clamping situation to complex workpiece geometries, and the flat friction pad ensures damage-free clamping. In this way, Ziegler can remove a workpiece with an intact surface from the machine at the end of the milling process. The VCBL-HD holds both thin construction and standard furniture parts as well as heavy solid wood with a rough surface safely and eliminates the need to change clamping devices.