IO-Link Wireless

Wireless, flexible, reliable – real-time communication meets innovation. Discover scalable solutions!

Experience the wireless future of Industry 4.0: IO-Link Wireless connects sensors and actuators to your controller in real time – for greater freedom of movement, easy installation and maximum process reliability.

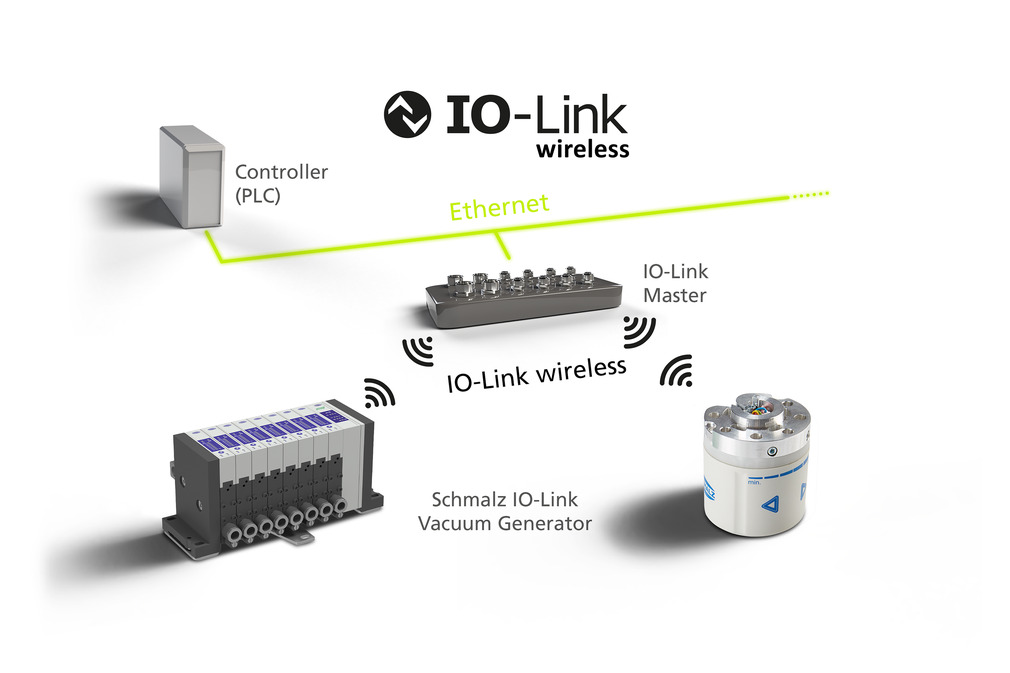

As a point-to-point communication standard in automation technology, IO-Link is revolutionizing bidirectional communication between control units and field devices.

IO-Link is a globally established, manufacturer-independent communication standard that connects sensors such as pressure sensors and actuators such as ejectors or valves to the controller. IO-Link Wireless extends this technology with a robust, wireless interface in accordance with IEC 61131-9.

This technology is ideal for applications where cable laying is difficult or cost-intensive – for example in robotics, packaging or mobile systems. It guarantees safe, interference-free and real-time data transmission that can be seamlessly integrated into existing automation systems.

Visit our FAQ and get all the answers about IO-Link!

IO-Link Wireless is standardized according to IEC 61131-9 and guarantees interoperability between devices from different manufacturers.

Data transmission with latencies of approx. 5 ms enables control tasks in real time.

Parameterization, diagnostics and control commands are transmitted reliably.

High fault tolerance (fault rate 10-⁹) and interference immunity even in industrial environments.

Data is the backbone of modern machines – with wireless technology and innovative IO-Link wireless devices, Schmalz is shaping the industrial future and offering companies reliable service and support for sustainable automation.∼ Michael Pojtinger, Head of Business Development Process, Vacuum Automation

Schmalz offers tailored IO-Link Wireless solutions for numerous industries:

IO-Link Wireless consists of the following components:

Technical Comparison: Wired vs. Wireless

| Criterion | Wired (e.g. IO-Link) | IO-Link Wireless |

|---|---|---|

| Flexibility | ❌ Permanently installed | ✅ Wireless placement |

| Installation | ❌ More complex cabling | ✅ Plug and play |

| Scalability | ❌ Conversion required | ✅ Up to 40 devices can be easily added |

| Latency | ✅ <1 ms | ✅ ~5 ms (real-time capable) |

| Mobility | ❌ None | ✅ Mobile and dynamic applications |

| Retrofit | ❌ More expensive and more complex | ✅ Simple and cost-effective |

Detailed information about Ethernet

Find more about communication NFC technologie.

Find more about communication interfaces IO-Link.

Find out which communication interface suits you best.

Johannes-Schmalz-Str.1

72293 Glatten

Germany