Electronics production: ESD-safe and leaving few marks

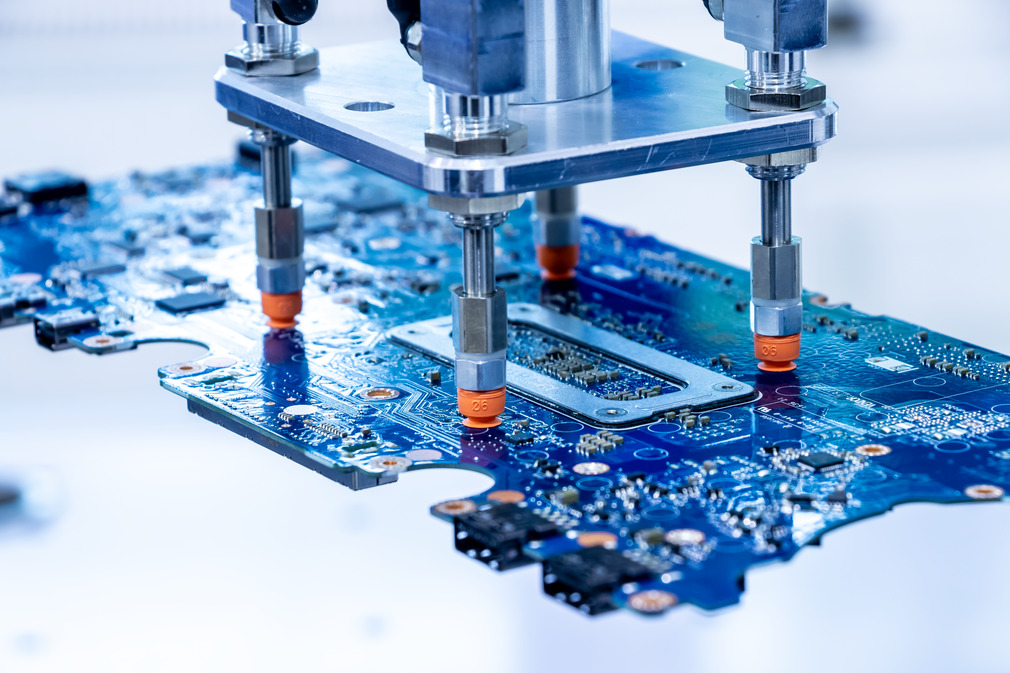

Safe handling of sensitive electronics: The new suction cup made of HT1-ESD material moves printed-circuit boards leaving few marks and reliably protects against electrostatic discharge.

A tiny fingerprint on a semiconductor wafer, a barely noticeable electrostatic discharge, conductive soot that can release particles. The result: costly production errors or contamination. Until now, manufacturers have had to make compromises. Schmalz now combines all requirements in the new suction cup material HT1-ESD.

The high-performance material combines the properties of the two already proven materials HT1 and NBR-ESD. The HT1 component ensures leaving few marks when handling, as it leaves only minimal chemical residue on components. At the same time, it withstands heat up to 170 degrees Celsius without losing its mechanical or chemical properties. The high ozone resistance and wear resistance significantly extend the service life of the suction cups. Cracks or material degradation do not occur, ensuring operational safety.

Without critical additives

Schmalz improves the benefits for users through the material composition: thanks to NBR-ESD, the HT1-ESD suction cup material does not require external coatings and conductive carbon black.These conductive additives can detach with wear, impair ESD protection, contaminate the process and lead to yield losses. Thanks to the new HT1-ESD material, electronics manufacturers benefit from clean surfaces that significantly reduce waste. Maintenance and downtimes are reduced and machine availability is increased.

Thanks to minimized impressions and maximized ESD protection, the suction cups made of HT1-ESD material are suitable for various applications in electronics production: from household appliances and consumer electronics to semiconductor production and final assembly. Schmalz offers the suction cups in different shapes to suit all workpieces.

Systematic wafer handling: suction cups made of the material HT1-ESD protect against electrostatic discharge and ensure the surface quality of sensitive electronic components.

Media contact

The Schmalz press team will be happy to answer any questions you may have.