- PHASE-OUT ITEM

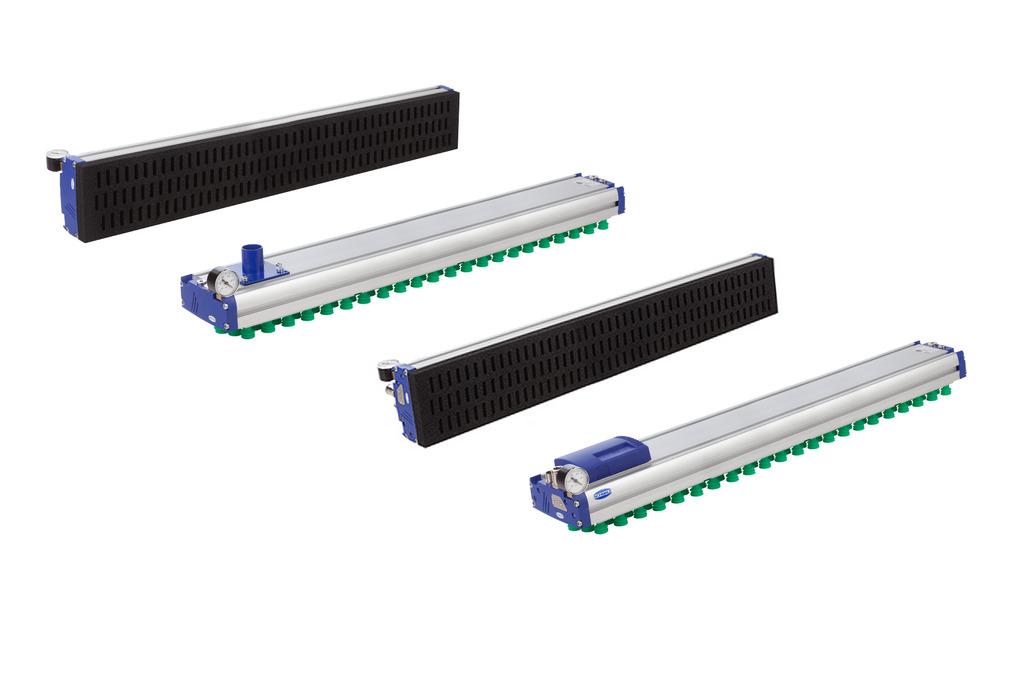

Vacuum Area Gripping System FXP / FMP

- Universal gripper for automated palletizing and depalletizing, commissioning and sorting

- Dimensions: 442 x 130 to 1,432 x 130 mm

- Sealing element: sealing foam, suction cups

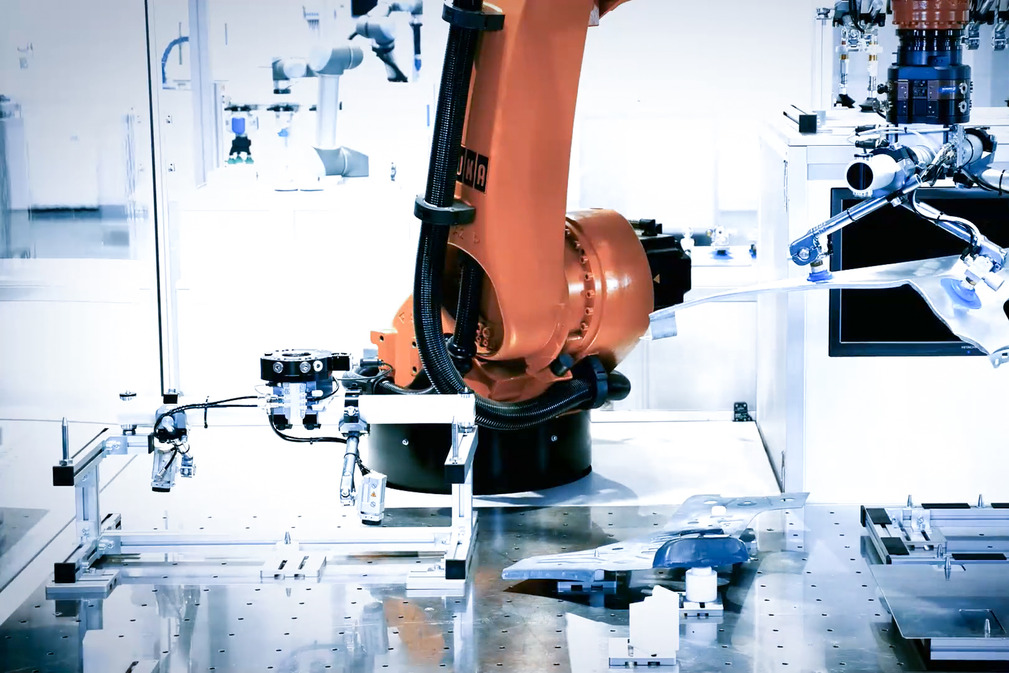

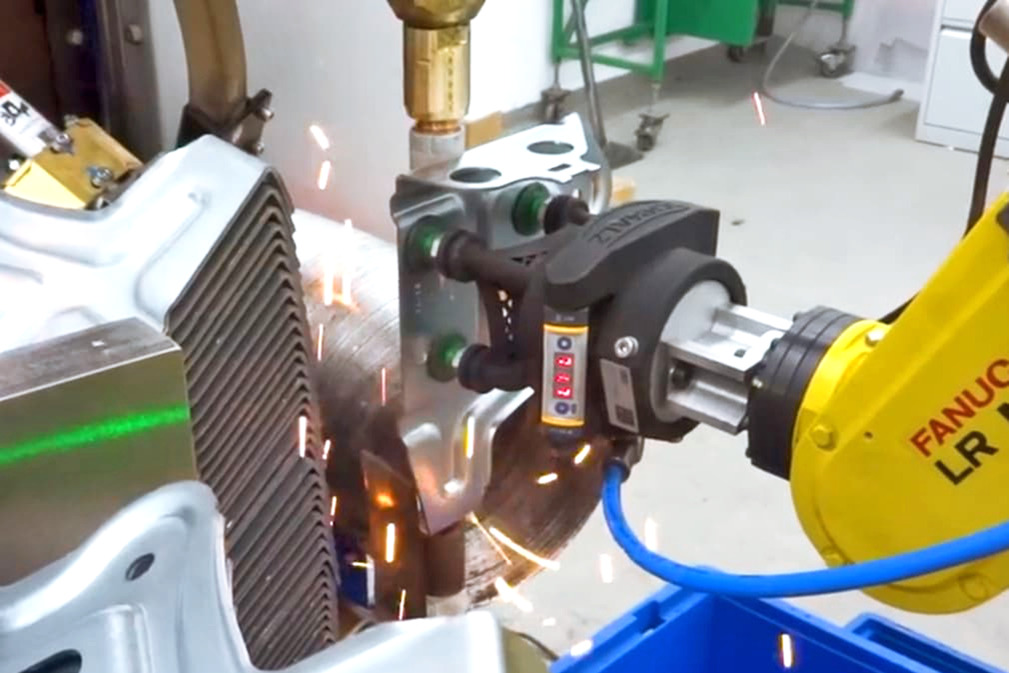

Aluminum structures are produced that are bent into shape after being sawn. A pre-configured vacuum gripper system from Schmalz, mounted on a robot, is used to automatically handle the sections between the individual work stages. The video shows a gripper system which comprises four area grippers FXC with integrated vacuum generation.

The video shows a gripping system that consists of four FXC area grippers with integrated vacuum generation. The compact and easy to install area grippers are equipped with numerous individual bellows suction cups. With their 2.5 corrugations, the suction cups fit flexibly to the structure of the warped sections. If individual suction cups are not applied, check valves prevent leackages in the system. 5 sections are taken up by a band and then transferred and palletised in each of two suction cycles. Narrow bars are used as separators between the individual pallet layers to prevent direct contact between the aluminium parts. The gripper system has a second vacuum circuit and four additional suction cups attached to the outside of the gripper system for this handling procedure. Two compact ejectors that are particularly energy-efficient thanks to an air-saving function generate the vacuum.

Discover application examples of the product in various industries - user-friendly, informative and practical.

No suitable videos found? Then take a look at our media center.