Operating principles of vacuum generation

Venturi principle

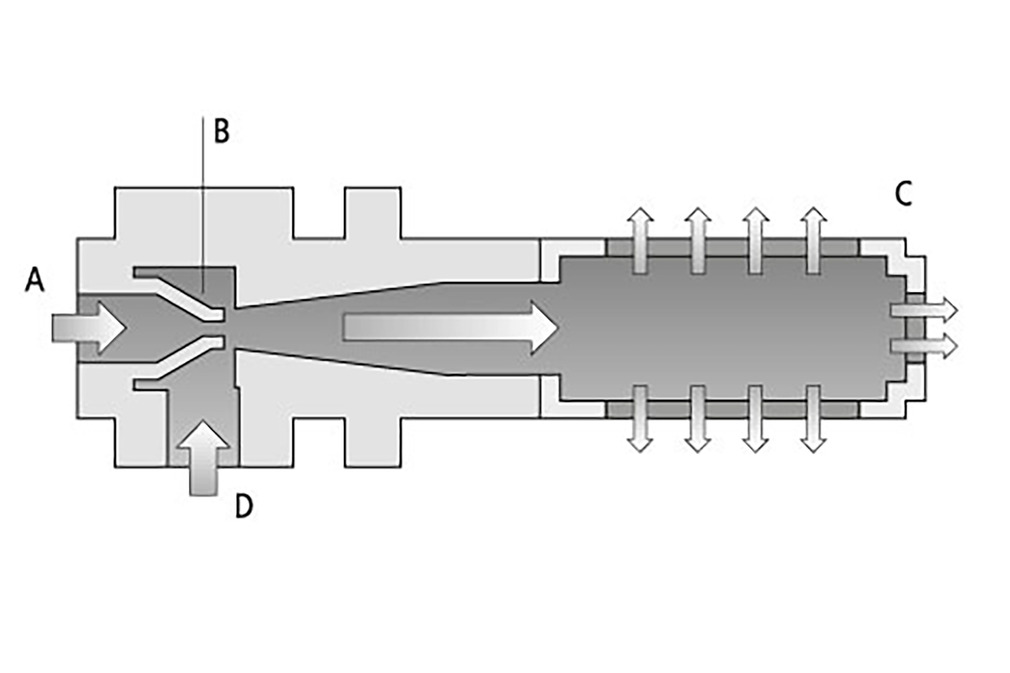

Operating principle

- Pneumatic vacuum generators function based on the Venturi principle

- Compressed air is introduced into the ejector (A)

- Due to the reduced cross-section of the motive nozzle (the Venturi nozzle [B]), the compressed air is accelerated. The dynamic pressure increases, while the static air pressure simultaneously decreases.

- Once it has passed the motive nozzle, the accelerated air expands and a vacuum is generated

- Air is "sucked" through the vacuum connection (D) into the ejector

- The compressed air escapes from the ejector through the silencer (C) together with the "sucked-in" air.

Advantages

- Vacuum generators that function according to the Venturi principle are especially suitable for very high accelerations

- Vacuum grippers can be controlled individually

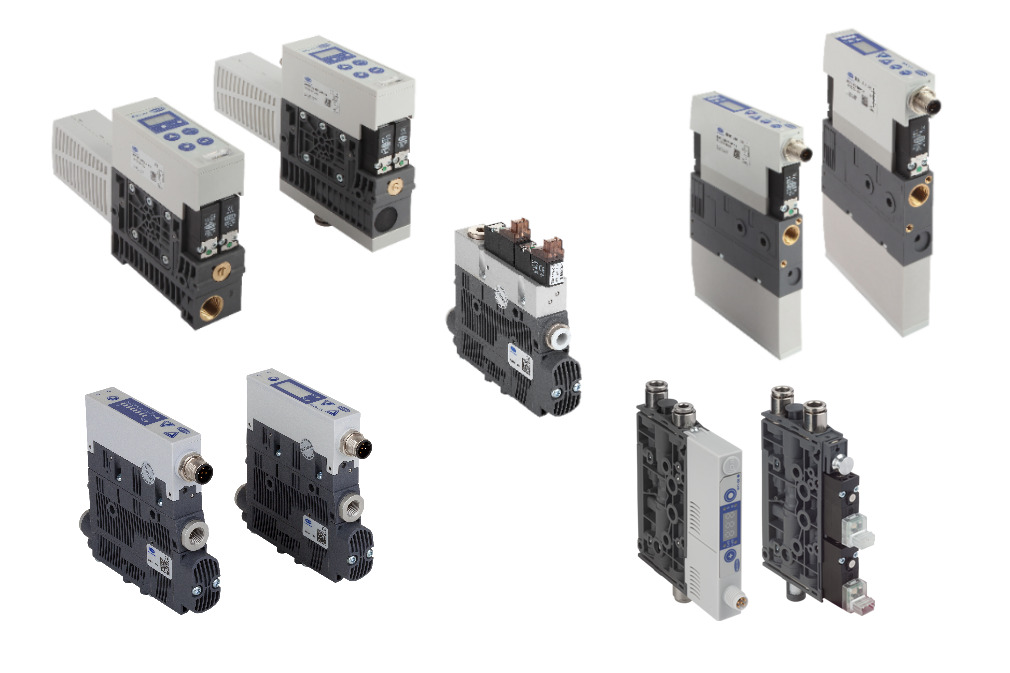

- Ejectors in different designs for centralized and decentralized vacuum generation depending on the application

- Various power classes to suit the workpiece and application

Bernoulli's principle

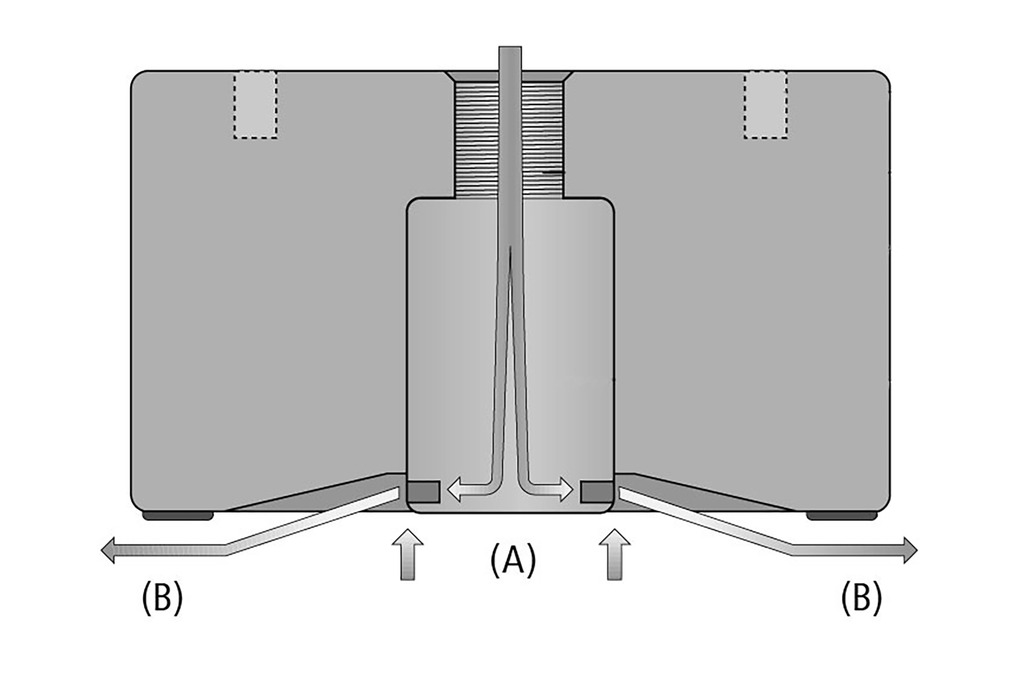

Operating principle

- Pneumatic operation with integrated vacuum generation

- Compressed air escapes through holes in the suction cup and is greatly accelerated when doing so

- Due to the increase in speed, the static pressure falls and a vacuum is produced (A) ("Bernoulli Equation")

- The accelerated air escapes to the side (B); an "air cushion" is produced between the floating suction pad and workpiece

- Leakage is compensated for through a high flow rate, which means that even porous workpieces can be handled and separated

- The Bernoulli effect ensures that the workpieces are handled with minimal contact

- Floating suction cups function according to Bernoulli's principle

Advantages

- Low-contact, gentle handling of thin and sensitive workpieces thanks to the Bernoulli effect

- Safe separation of thin and porous workpieces

The Coanda principle

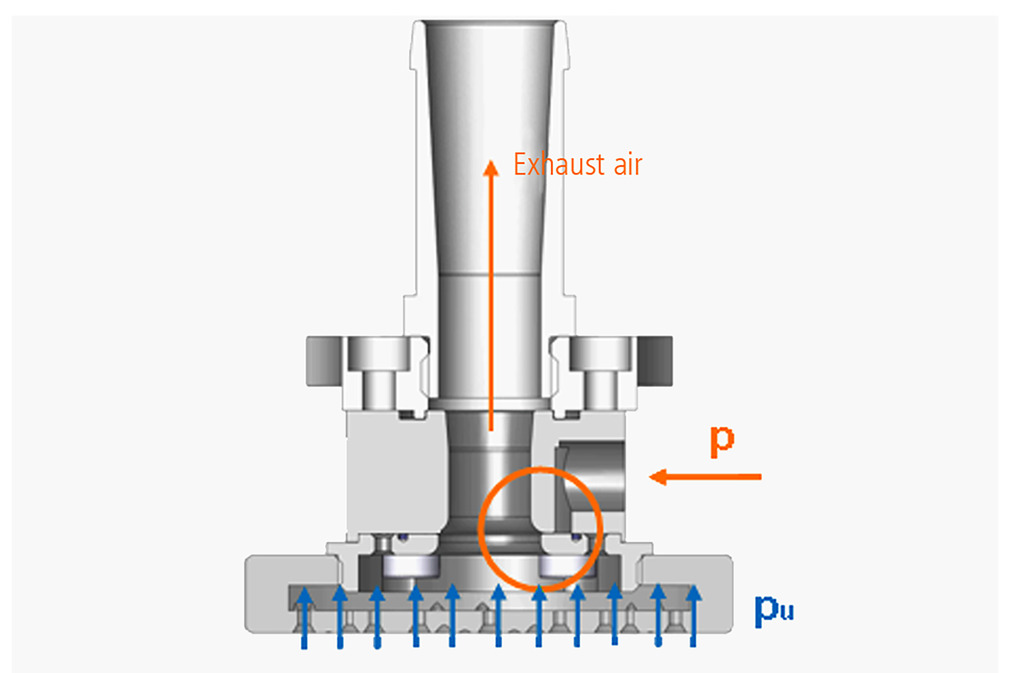

Operating principle

- Pneumatic operation with integrated vacuum generation

- With the Coanda principle, compressed air is guided through an annular gap which accelerates it

- The increase in the flow speed results in the "Coanda effect" in which the escaping air follows a convex surface

- The air flowing along the surface produces suction ("entrainment") in the ambient air

Advantages

- High suction rate and low air consumption (the required operating pressure is 1 to 5 bar) due to the Coanda effect

- Large contact surface with narrowly positioned vacuum openings prevent the workpiece from being sucked in or damaged

- Suction areas can also be partly engaged