Gentle hold for thick and thin

The combination makes the difference: aluminum makes the VCBL-HD stable and vibration-resistant, elastomer is gentle on all surfaces.

From walk-in eyes to wave-shaped shelving systems and curved dog bowls – Ziegler Holz- und Kunststofftechnik is known for complex three-dimensional molded parts. The furniture manufacturer also supplies trade show and store fitters, caravan manufacturers and the packaging industry with classic solid wood objects. The supplier mills the objects for this from various materials on CNC machines in formats up to 5,500 x 1,800 millimeters.

The family business began in a small furniture workshop in Lossburg-Lombach, south of Freudenstadt. Here, company founder Kurt Ziegler manufactured individual wooden workpieces for private customers. In the 1990s, the second generation of entrepreneurs, Erhard and Heidi Ziegler, got into CNC wood working. In 1994, they began what Ziegler Holz- und Kunststofftechnik is known for today. In the meantime, the third generation is in charge, and the one-man business has become a successful supplier to the furniture industry, with 16 employees producing sophisticated wooden parts of all kinds on 3,000 square meters - from individual pieces to large-scale production.

When kilometers and competence win

"We have been milling on HOMAG Group machines from the very beginning and have been using Schmalz clamping systems for just as long," explains Managing Director Michael Ziegler. The proximity was initially the decisive factor: Both companies are right on our doorstep. Today, Schmalz also convinces with its competence and the fast and uncomplicated contact. The most recent project was to make CNC machining even more flexible - with the help of a new clamping solution. Ziegler was not only the user, but also a partner in the final development process. Because the vacuum block was not yet on the market.

From A to HD

Previously, Ziegler alternated between the VCBL-A-K2 aluminum vacuum block and the VCBL-K2 with plastic main body, depending on the application. The VCBL-A version enables maximum cutting parameters even on rough surfaces and heavy solid wood boards, thanks to its special friction pad made of emery cloth. However, this was a source of concern for the carpenters: "Time and again, we had to rework workpieces because the rough coating roughened the surfaces," clarifies Ziegler. The advantage of the VCBL-A vacuum block, however, is its main body made of aluminum, which creates a low-vibration connection between the machine table and the workpiece. This is important when machining solid wood, as higher cutting forces and vibrations act here and the workpieces have a rougher surface.

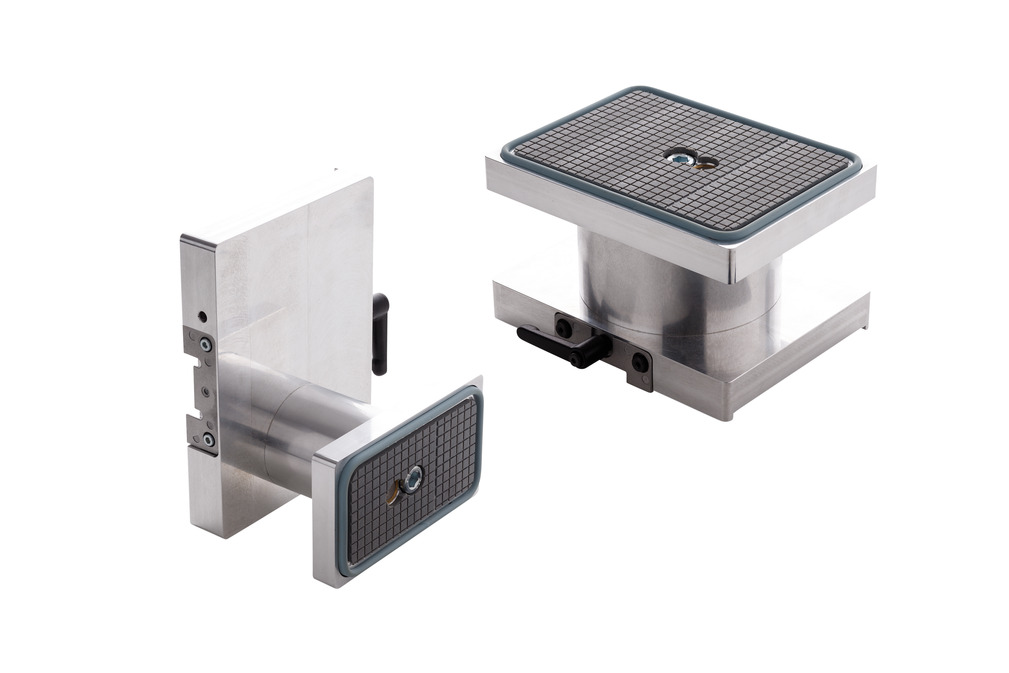

But solid wood is rarely on the table at Ziegler these days. For the production of its standard furniture parts, Ziegler turns to the VCBL-K2. Although this alternative is gentle on the surface thanks to the elastomer suction plate, its design is not sufficiently stable for solid wood. Ziegler wanted to be more efficient and flexible, able to set up and rework faster. "With this desire for an all-in-one solution, we turned to Schmalz, who presented us with the VCBL-HD," Ziegler recalls. The VCBL-HD combines the best of both vacuum block worlds: A flat support with an elastomer friction pad and a flexible sealing gasket sits on an aluminum main body. This holds both thin construction and standard furniture parts as well as solid wood with rough surfaces safely and makes a change of clamping devices unnecessary.

Challenging: In practice, the solid wood parts vibrated during milling. "With Ziegler as our development partner, we had the chance to perfect the HD variant. We reinforcing the design, reduced the restoring force of the sealings and roughened the friction pad somewhat," explains Matthias Schmider, product manager at Schmalz. The new vacuum block can do even more: it also enables efficient machining of the mineral-organic composite material Corian and of HPL (High Pressure Laminate). "That was previously difficult or impossible to implement. This is because, due to their strength, both materials cannot be machined with the standard K2 suction cup, or only at very low feed rates, while the VCBL-A would have damaged the surfaces of the workpieces," Schmider sucks.

At Ziegler, the new vacuum blocks have been in use since mid-2022: "When we lay up solid wood, we are much more flexible, have fewer setup processes and are faster in throughput. In addition, we can also clamp thin-walled and sensitive workpieces with the HD variant. This eliminates the need for reworking." The carpenter is even more flexible thanks to the rotatable version of the suction plate. Thanks to the 15-degree grid, he can adapt the clamping situation optimally even to complex workpiece geometries. The flat friction pad ensures damage-free clamping, so that Ziegler can be sure of being able to remove a workpiece with an intact surface from the machine at the end of the milling process.

The VCBL-HD safely holds thin construction and standard furniture parts as well as heavy solid wood with rough surfaces and eliminates the need to change clamping devices.

Media contact

The Schmalz press team will be happy to answer any questions you may have.