Electrical vacuum generation

Electrical vacuum generation describes the generation of vacuum using purely electrical devices such as vacuum pumps or vacuum blowers.

This technology is not only an alternative to compressed air-driven ejectors, but also enables flexible use in many other areas of application.

Operation mode and design of electrical vacuum generators

An electric vacuum generator generates vacuum using an electrically driven vacuum pump or vacuum blower - completely without compressed air. While pneumatic systems use electrically generated compressed air, for example according to the Venturi principle, to generate vacuum, electric vacuum pumps and vacuum blowers create the vacuum directly in the device. The vacuum pump or vacuum blower sucks air molecules (gas particles) out of an enclosed space until the pressure inside drops below atmospheric pressure and a vacuum is created. Depending on the application, different principles of operation are used, such as the diaphragm pump, rotary vane pump, claw pump or side channel blower.

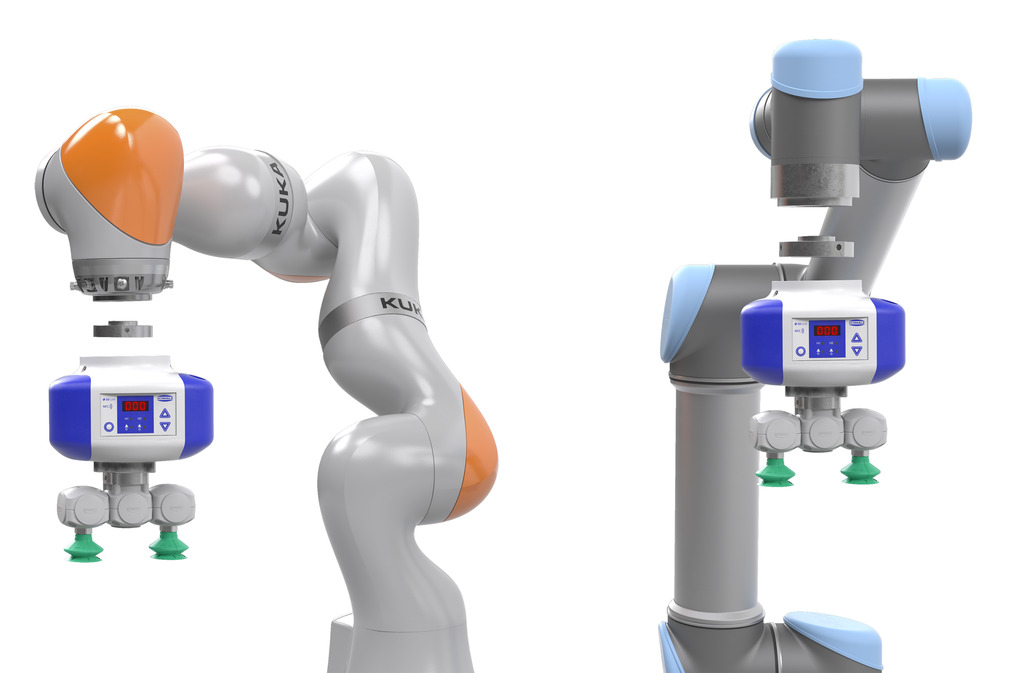

To meet the requirements of automation, Schmalz combines these electrical devices with additional technology. Sensors monitor the vacuum, the control system adapts the power to the actual demand and process data can be transferred to higher-level systems via digital communication interfaces such as IO-Link or fieldbus.

As vacuum generation is completely electrical, no complex compressed air infrastructure is required in addition to the electrical energy source. This means that electrical vacuum generators can be used anywhere and are particularly flexible.

Industry examples: Packaging, wood and logistics

In the packaging industry, electrical vacuum generation enables efficient pick and place applications and reliable end-of-line processes. Thanks to the software-supported adaptation of parameters, format changes can be implemented quickly, allowing systems to work more productively and remain competitive.

The technology also shows its strengths in wood processing. When gripping, clamping and moving sheets or beams, a stable vacuum ensures safe processes in sawmills, joineries and automated furniture production. This means that even large and porous workpieces can be handled safely.

In logistics, electrical vacuum generation supports modern intralogistics processes, such as the handling of pallets or warehouse picking. Flexible vacuum systems enable quick adaptation to different flows of goods and thus contribute to smooth and energy-efficient control of the material flow.

Související pojmy

Further information

Electrical vacuum generation

Compact, energy-efficient, compressed air-free - vacuum technology rethought. Discover electrical vacuum generation for industry and automation.

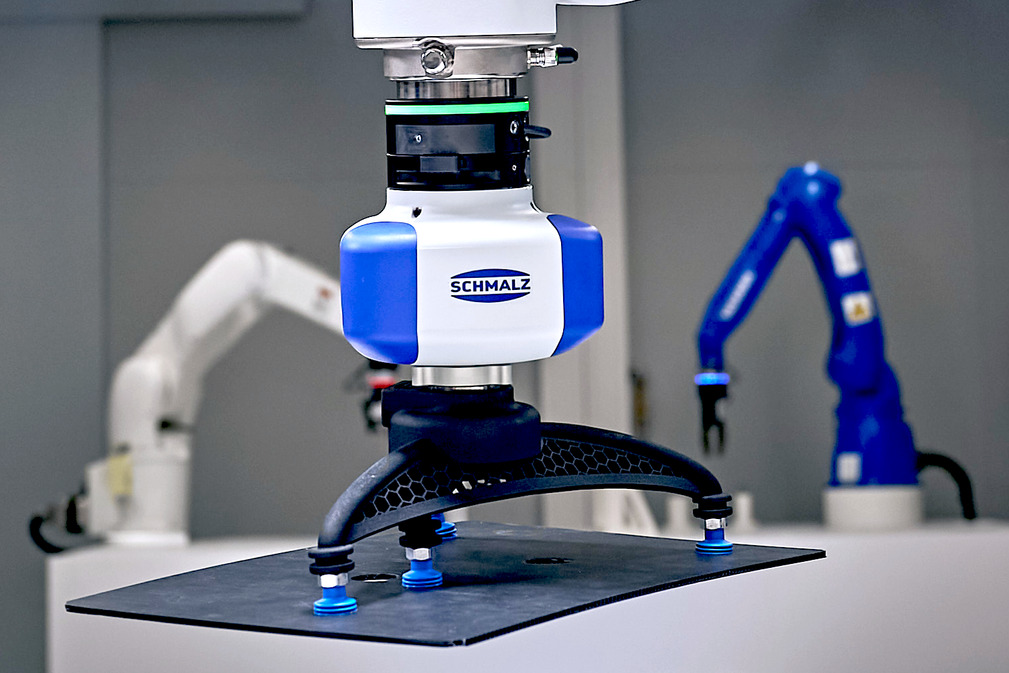

Vacuum Technology for Robotics

Robotics solutions from Schmalz are characterized by maximum precision, safety and process control in the gripping process.

Vacuum generator selection aid

Use the selection aid to help you choose the right vacuum generator. Discover the best-fit solution for your application here!

Vacuum generator

Vacuum generators provide the vacuum for handling workpieces pneumatically or electrically. Explore electric vacuum generation technologies here!