Approach to System Design

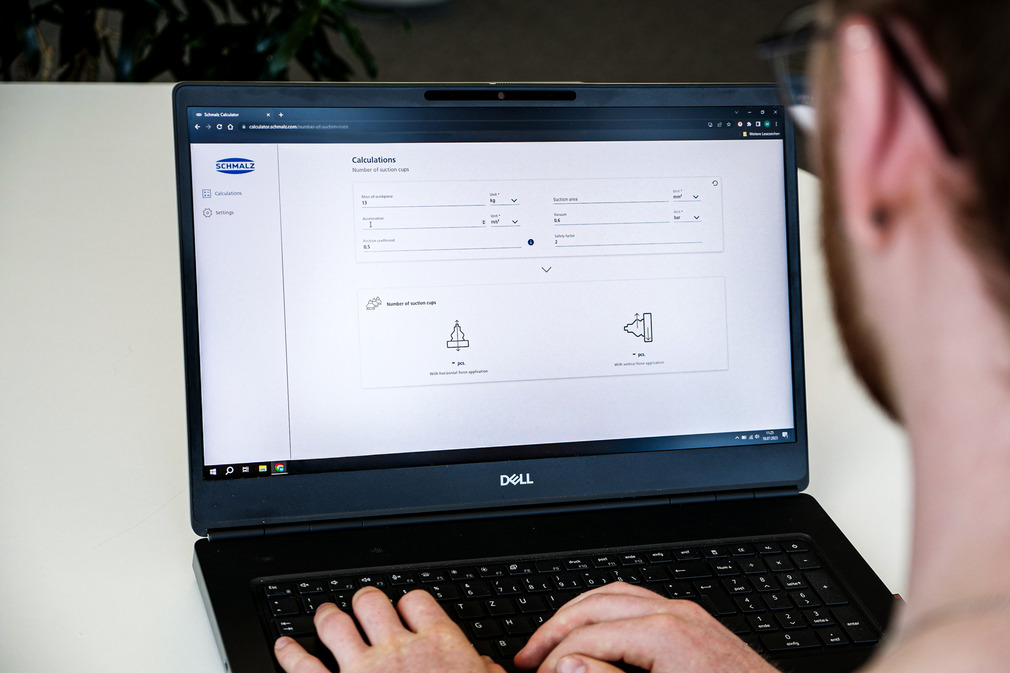

The implementation from theory to practice is shown with a system design based on an example. The Schmalz Calculator in the "Services" section provides helpful support for system design.

Flowchart for system design

- Calculation of forces

- Suction cups

- Mounting elements

- Vacuum hoses

- Distributors

- Vacuum generators

- Solenoid valves

- Vacuum switches

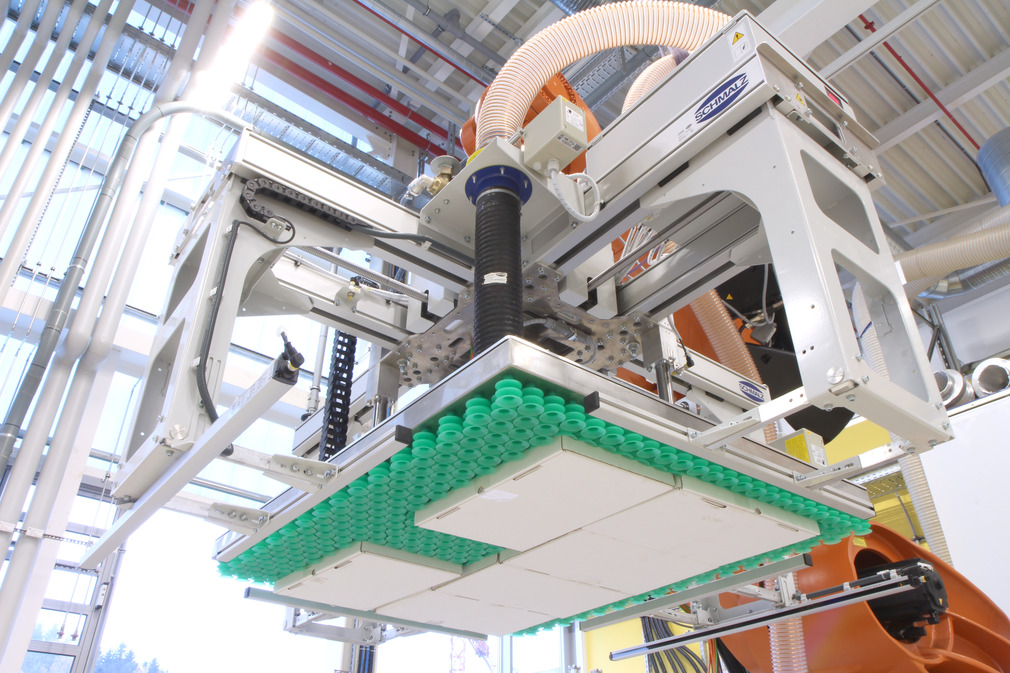

The following calculations are based on this application:

Workpiece

Material: Steel sheets, stacked on a pallet

Surface: Smooth, level, dry

Dimensions:

Length: max. 2,500 mm

Width: max. 1,250 mm

Thickness: max. 2.5 mm

Weight: approx. 60 kg

Handling system

Used system: Gantry handling system

Existing compressed air: 8 bar

Control voltage: 24 V DC

Working sequence: Horizontal Pick & Place

A steel sheet is picked up from a pallet, lifted, transported horizontally and deposited in a machining center.

Max. acceleration:

X, Y axis: 5 m/s2

Z axis: 5 m/s2

Cycle time: 30 s

Scheduled time:

for pick-up: < 1s

for releasing: < 1s

Schmalz Calculator

Use our Schmalz Calculator as a little helper when designing your vacuum system.

Weight Calculation of a Workpiece

It is important to determine the weight (m) of the workpiece to continue with additional calculations. It is calculated based on the following formula.

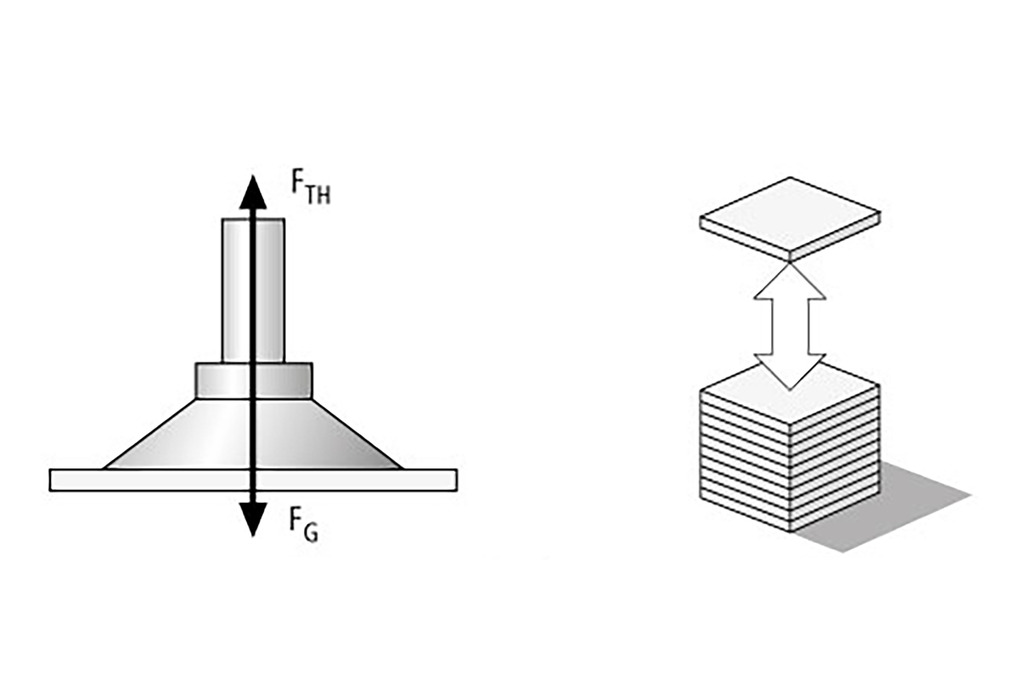

Theoretical Holding Force of a Suction Cup

To calculate the theoretical holding force, we show and describe the three most important and most frequently occurring load cases (handling sequences).

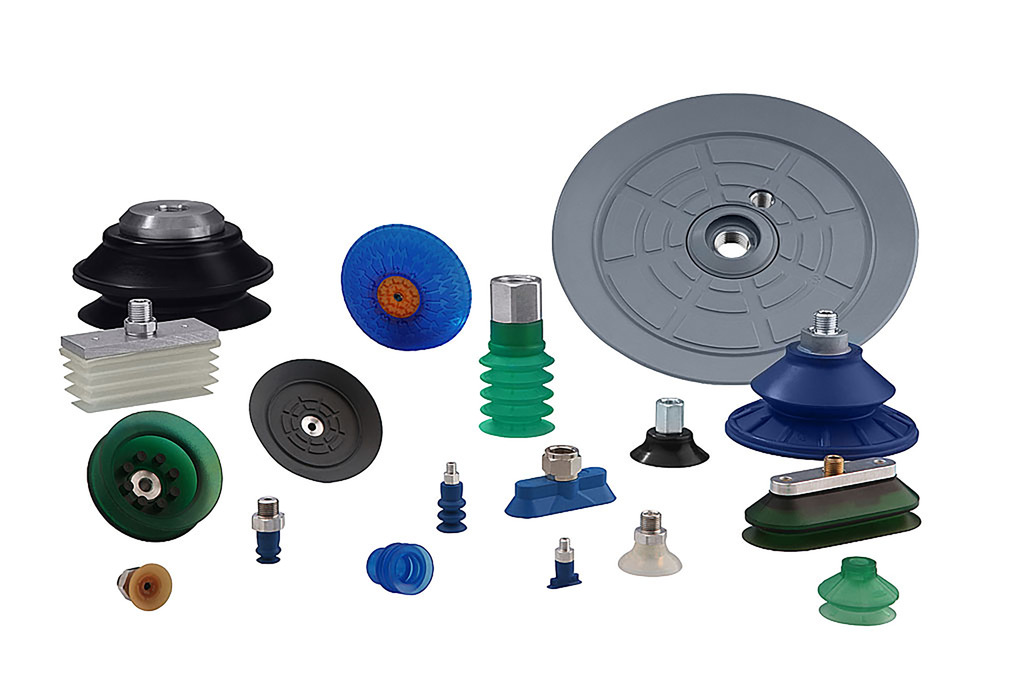

Suction Cup Selection

In order to select the right suction cup, you must take the ambient conditions into consideration.

Mounting Elements Selection

The mounting of the suction cups is usually selected according to customer requirements. But there may be compelling reasons for a particular type of mounting.

Vacuum Hose Selection

Schmalz selects the vacuum hoses to match the size of the flow rates as well as the size of the suction cups.

Distributor Selection

The distributor has to match the used hose diameter and the number of suction cups.

Vacuum Generator Selection

The selection of the matching vacuum generator (ejector, pump or blower) is determined by several factors.

Valve Technology Selection

The selection of the right valve technology depends on the suction rate of the generator and the control voltage.

Vacuum Switch Selection

Vacuum switches and manometers are usually selected based on the existing requirements regarding functionality and switching frequency.

Calculation of Evacuation Times

Calculate evacuation times and judge the cost-efficiency of your complete system from Schmalz.

Test with Original Parts

In addition to calculations, tests and original parts demonstrate the efficiency of Schmalz vacuum systems.