Electrical Vacuum Generation

No compressed air. Future-ready solutions. Vacuum Technology, reimagined.

No compressed air available or particularly high power required? No problem! Discover the electrical future of vacuum technology: electrical vacuum generators such as vacuum pumps and vacuum blowers open up new possibilities for the use of vacuum technology in industrial automation. Schmalz offers the right solution for every application.

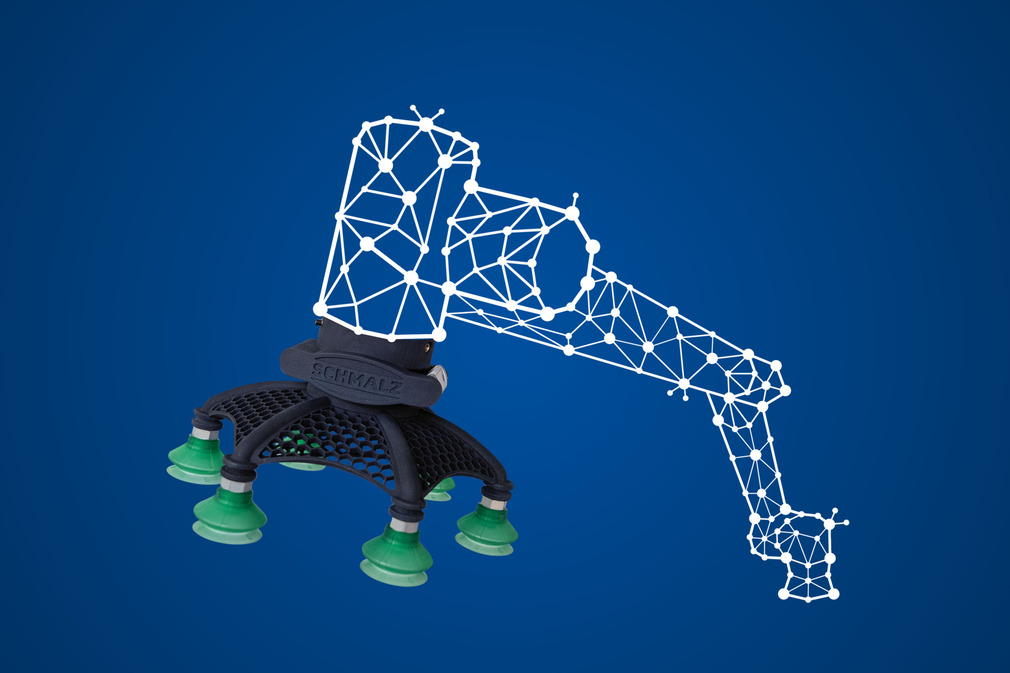

Our rotary vane pumps ensure clean processes, flexible use and maximum performance – even under the toughest conditions. Supplementing this, electrical vacuum generators such as our diaphragm pumps offer a compact, energy-efficient and compressed air-free solution that combines efficiency, reliability and future-proofing. This makes vacuum technology the engine for a more sustainable, flexible industry, automation and robotics.

Electrical vacuum generators such as pumps or blowers generate vacuum purely electrically. In contrast to pneumatic systems, vacuum generation takes place without the use of compressed air. Depending on the version, this results in higher energy efficiency and reduced operating costs.

If compressed air is not available or maximum power with high suction capacity is required, the Schmalz portfolio offers numerous powerful electrical vacuum generators. Thanks to various principles of operation, they achieve exactly the suction flow rates and vacuum levels that you need for your handling, lifting and clamping processes.

Electrical vacuum generation as an efficient alternative to pneumatic vacuum generation.

Find the right vacuum generator for your application.

Electrical vacuum generation is flexible and can be used in robotics, packaging, wood working and other industries.

Discover the electrical vacuum generators from Schmalz.

"We want to create alternatives that reduce energy consumption and still function when no or too little compressed air is available."∼ Dr. Kurt Schmalz, Managing Shareholder of J. Schmalz GmbH

| Type | Advantages | Industries | Example applications | Example products |

|---|---|---|---|---|

| Rotary vane pump |

|

|

|

|

| Claw pump |

|

|

|

|

| Side channel blower |

|

|

|

|

| Diaphragm pump |

|

|

|

Discover how Schmalz shapes innovations for the future with cutting-edge technologies and deep know-how.

Sustainable products with a tangible impact: innovations from Schmalz reduce emissions along the supply chain and lower energy costs.

Your point of contact for EOAT: specialist knowledge, applications and links to products, media and the latest news.

Robotics solutions from Schmalz are characterized by maximum precision, safety and process control in the gripping process.